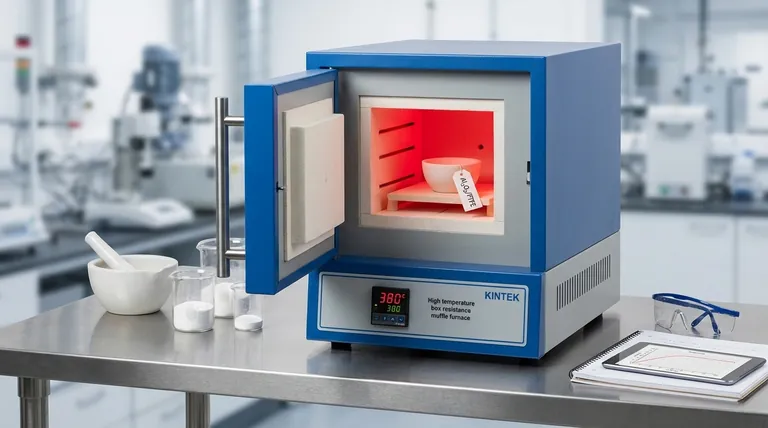

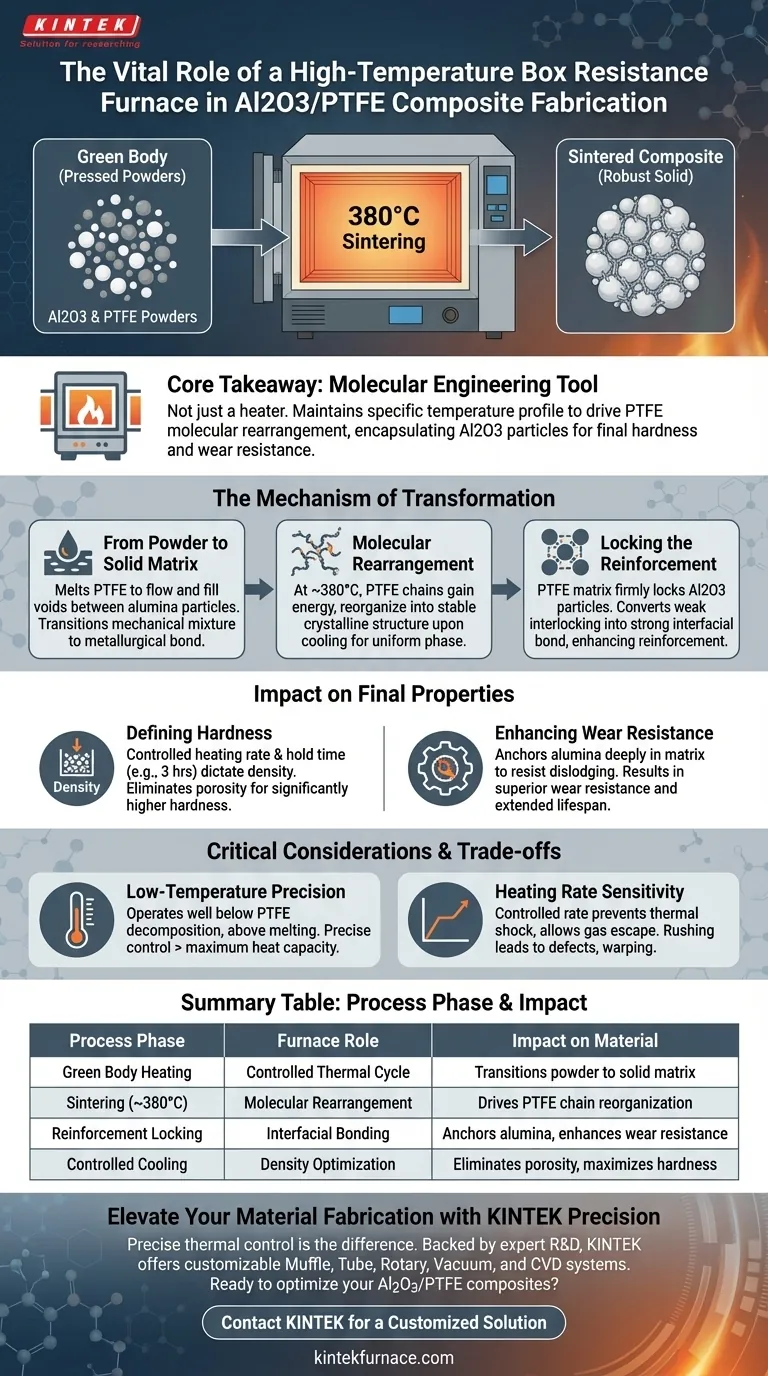

The high-temperature box resistance furnace acts as the critical vessel for sintering Al2O3/PTFE (alumina/polytetrafluoroethylene) composites. It transforms pressed "green bodies"—fragile compacted powders—into robust solid materials by subjecting them to a precisely controlled thermal cycle, typically reaching temperatures around 380 degrees Celsius. This process facilitates the physical bonding required to stabilize the composite structure.

Core Takeaway The furnace is not merely a heater; it is a tool for molecular engineering. By maintaining a specific temperature profile, it drives the rearrangement of PTFE molecular chains to encapsulate alumina particles, directly determining the final hardness and wear resistance of the composite.

The Mechanism of Transformation

From Powder to Solid Matrix

The primary function of the furnace is to transition the material from a mechanical mixture to a metallurgical bond.

Before entering the furnace, the Al2O3 and PTFE exist as pressed powders, known as a green body.

The furnace provides the thermal energy necessary to melt the PTFE, allowing it to flow and fill the voids between the alumina particles.

Molecular Rearrangement

At the specific sintering temperature (e.g., 380°C), the PTFE molecular chains gain enough energy to move freely.

This allows for molecular rearrangement, where the polymer chains reorganize into a more stable, crystalline structure upon cooling.

This rearrangement is essential for creating a uniform continuous phase that holds the composite together.

Locking the Reinforcement

The furnace environment ensures that the PTFE matrix firmly locks the alumina (Al2O3) particles in place.

Without this "melt bonding," the alumina acts merely as a loose filler rather than a reinforcing agent.

The thermal treatment converts the weak mechanical interlocking of the green body into a strong interfacial bond.

Impact on Final Properties

Defining Hardness

The heating rate and holding time (such as a 3-hour hold) controlled by the furnace dictate the density of the final part.

Proper sintering eliminates porosity, resulting in a composite with significantly higher hardness.

If the temperature is too low, the particles will not bond sufficient; if too high, the polymer may degrade.

Enhancing Wear Resistance

The ultimate goal of adding alumina to PTFE is to improve wear characteristics.

The furnace ensures that the alumina is anchored deeply enough within the matrix to resist being dislodged during friction.

A well-sintered composite exhibits superior wear resistance, extending the lifespan of the component in industrial applications.

Critical Considerations and Trade-offs

The Necessity of Precision

While box furnaces are capable of very high temperatures (often used for metals at 900°C+), processing Al2O3/PTFE requires low-temperature precision.

You must operate well below the decomposition temperature of PTFE while staying above its melting point.

The trade-off is that while the furnace can go hotter, doing so would destroy the polymer matrix; precise control at lower ranges is more critical than maximum heat capacity.

Heating Rate Sensitivity

The rate at which the furnace ramps up temperature is just as important as the final temperature.

A controlled heating rate prevents thermal shock and allows trapped gases to escape before the surface seals.

Rushing this process in the furnace can lead to internal defects, warping, or inconsistent material properties.

Making the Right Choice for Your Goal

To maximize the performance of your Al2O3/PTFE composites, focus on the specific parameters of your thermal treatment.

- If your primary focus is Structural Integrity: Ensure your furnace program includes a sufficient hold time (e.g., 3 hours) to allow complete molecular rearrangement and bonding.

- If your primary focus is Surface Durability: Prioritize a precise heating rate to ensure the alumina particles are evenly locked into the matrix without inducing thermal stress defects.

The furnace transforms potential into performance; precise thermal control is the only difference between a pile of powder and a durable industrial component.

Summary Table:

| Process Phase | Furnace Role | Impact on Material |

|---|---|---|

| Green Body Heating | Controlled Thermal Cycle | Transitions powder mixture to a solid matrix |

| Sintering (~380°C) | Molecular Rearrangement | Drives PTFE chain reorganization and crystallization |

| Reinforcement Locking | Interfacial Bonding | Anchors alumina particles to enhance wear resistance |

| Controlled Cooling | Density Optimization | Eliminates porosity to maximize final material hardness |

Elevate Your Material Fabrication with KINTEK Precision

Precise thermal control is the difference between a brittle mixture and a high-performance composite. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique sintering requirements.

Whether you need low-temperature precision for PTFE or high-temp durability for advanced ceramics, our lab furnaces deliver the uniform heating and programmable accuracy your research demands.

Ready to optimize your Al2O3/PTFE composites? Contact KINTEK today for a customized solution!

Visual Guide

References

- Guofeng Zhao, Shifan Zhu. Al2O3/PTFE Composites for Marine Self-Lubricating Bearings: Modulation Mechanism of Alumina Particle Size on Material Mechanical Properties and Tribological Behavior. DOI: 10.3390/lubricants13090377

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the significance of using a box-type furnace for molybdenum aluminide coating oxidation? Master Thermal Testing

- In what industries are muffle furnaces commonly used? Essential for High-Temperature Material Processing

- How is a muffle furnace utilized in environmental analysis? Essential for Precise Organic and Inorganic Composition Testing

- What is the significance of using a laboratory high-temperature box furnace for Fe3O4@Al2O3 nanopowders?

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How does a high-temperature box resistance furnace contribute to the synthesis of silicon-doped ruthenium dioxide catalysts?

- What optional accessories are available for muffle furnaces? Enhance Precision and Safety in Your Lab

- What are some major industrial applications of a muffle furnace? Unlock Precision Heating for Your Industry