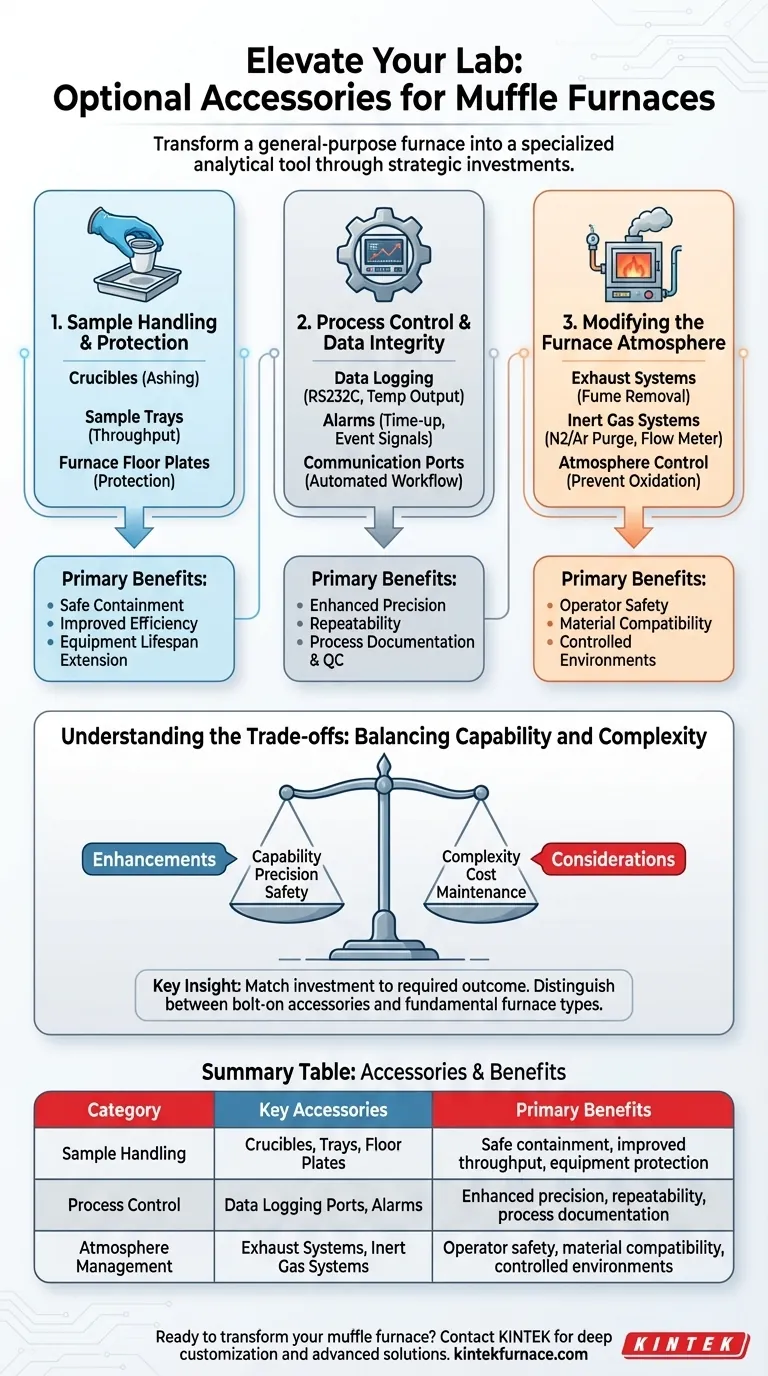

Optional accessories for a muffle furnace fall into three primary categories: those for sample handling, those for process control and data logging, and those for managing the furnace environment. These accessories range from simple consumables like crucibles and trays to sophisticated systems for controlling the internal atmosphere and integrating the furnace into a larger automated workflow.

The key is to understand that accessories are not mere add-ons; they are strategic investments that transform a general-purpose furnace into a specialized instrument. Your choice of accessories should be driven entirely by the specific process requirements of your application, whether it's for safety, precision, or material compatibility.

Optimizing Sample Handling and Protection

The most common accessories are those that interact directly with your samples and protect the furnace chamber itself. Their purpose is to ensure safe containment, improve throughput, and extend the lifespan of your equipment.

Crucibles and Sample Trays

Crucibles are ceramic or metal containers used to hold individual samples during high-temperature processes like ashing. They must be rated to withstand temperatures significantly higher than your process requires.

For processing multiple samples simultaneously, specialized sample trays or racks are used. These improve workflow efficiency and ensure even heating.

Furnace Floor Plates

A furnace floor plate, often made of a durable ceramic, is a sacrificial layer placed on the bottom of the heating chamber. Its sole purpose is to protect the furnace’s permanent insulation from spills, chemical attacks, or mechanical damage, making it a simple but critical investment.

Enhancing Process Control and Data Integrity

For applications requiring high precision, repeatability, and documentation, a second category of accessories focuses on monitoring and communication. These are essential for quality control and process validation.

Data Logging and Communication Ports

Modern furnaces can be equipped with various output terminals (RS232C, temperature output, operation signal) and external communication adapters. These allow the furnace to send real-time data to a computer or a central control system.

This capability is crucial for creating a documented heating profile, proving a process was completed to specification, and running the furnace as part of an automated system.

Alarms and Event Outputs

Time-up alarms and event output terminals are simple but effective tools for process management. They can audibly or electronically signal that a heating cycle is complete or that an error has occurred. This improves efficiency in a busy lab and allows for safe, unattended operation.

Modifying the Furnace Atmosphere

The most advanced accessories are those that alter the environment inside the furnace. These are necessary for processes where samples must be protected from air or when byproducts of the heating process must be safely managed.

Exhaust Systems

An exhaust or vent system is used to safely remove fumes, smoke, or moisture that may be released from a sample during heating. This is critical for operator safety when processing materials that produce hazardous off-gassing, such as in binder burnout applications.

Inert Gas Systems

For materials that must not oxidize at high temperatures, an inert gas system is essential. This accessory, often an N2 gas loading device with a flow meter, allows you to purge the ambient air from the chamber and replace it with an inert gas like nitrogen or argon.

The flow meter provides precise control over the gas environment, which is vital for achieving consistent results with sensitive materials.

Understanding the Trade-offs

Selecting accessories requires a cost-benefit analysis. While they enhance capability, they also introduce complexity and expense.

Cost vs. Required Precision

A simple ash content test may only require a basic crucible. However, a validated manufacturing process in the medical or aerospace industry will demand the precision and documentation provided by data logging and controlled atmosphere systems. Match the investment to the required outcome.

Integration and Maintenance

Accessories, particularly electronic and gas systems, increase the complexity of the furnace setup. They require proper installation, calibration, and operator training. This added maintenance overhead must be factored into the decision.

Accessories vs. Furnace Type

It is important to distinguish between bolt-on accessories and fundamental furnace designs. An inert gas port is an accessory. A fully vacuum-sealed chamber or a tilting furnace body is a different type of furnace altogether. Be clear on whether you need to augment an existing furnace or procure a different class of equipment.

Selecting the Right Accessories for Your Application

Your choice should be guided by your end goal. Evaluate your primary process need to determine which accessories will provide the most value.

- If your primary focus is basic ashing or heat treatment: Your essential accessories will be durable, high-temperature crucibles and a protective furnace floor plate.

- If your primary focus is process validation and quality control: Prioritize data logging capabilities, such as an RS232C port and temperature output terminals, for complete process traceability.

- If your primary focus is working with oxygen-sensitive materials: An inert gas inlet with a flow meter and a corresponding exhaust port are non-negotiable requirements.

- If your primary focus is operator safety and high throughput: Invest in an active exhaust system to manage fumes and alarm outputs to signal cycle completion.

By thoughtfully selecting the right accessories, you elevate your muffle furnace from a simple heat source to a precise and powerful analytical tool tailored to your specific needs.

Summary Table:

| Category | Key Accessories | Primary Benefits |

|---|---|---|

| Sample Handling | Crucibles, Trays, Floor Plates | Safe containment, improved throughput, equipment protection |

| Process Control | Data Logging Ports, Alarms | Enhanced precision, repeatability, process documentation |

| Atmosphere Management | Exhaust Systems, Inert Gas Systems | Operator safety, material compatibility, controlled environments |

Ready to transform your muffle furnace into a specialized tool? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you require accessories for enhanced sample handling, process control, or atmosphere management, we can help you achieve superior results. Contact us today to discuss how we can support your laboratory's goals!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO