At its core, a muffle furnace is an industrial workhorse for providing a uniform, high-temperature environment that is isolated from the byproducts of fuel combustion. This precise and clean heating capability makes it indispensable across a vast range of industrial applications, primarily for heat-treating metals, conducting material analysis through ashing, and manufacturing specialized products like ceramics.

The true value of a muffle furnace is not just its ability to generate high heat, but its "muffle"—an insulating chamber that isolates the sample from heating elements and contaminants. This ensures that the process is defined purely by temperature, not by a reactive chemical environment.

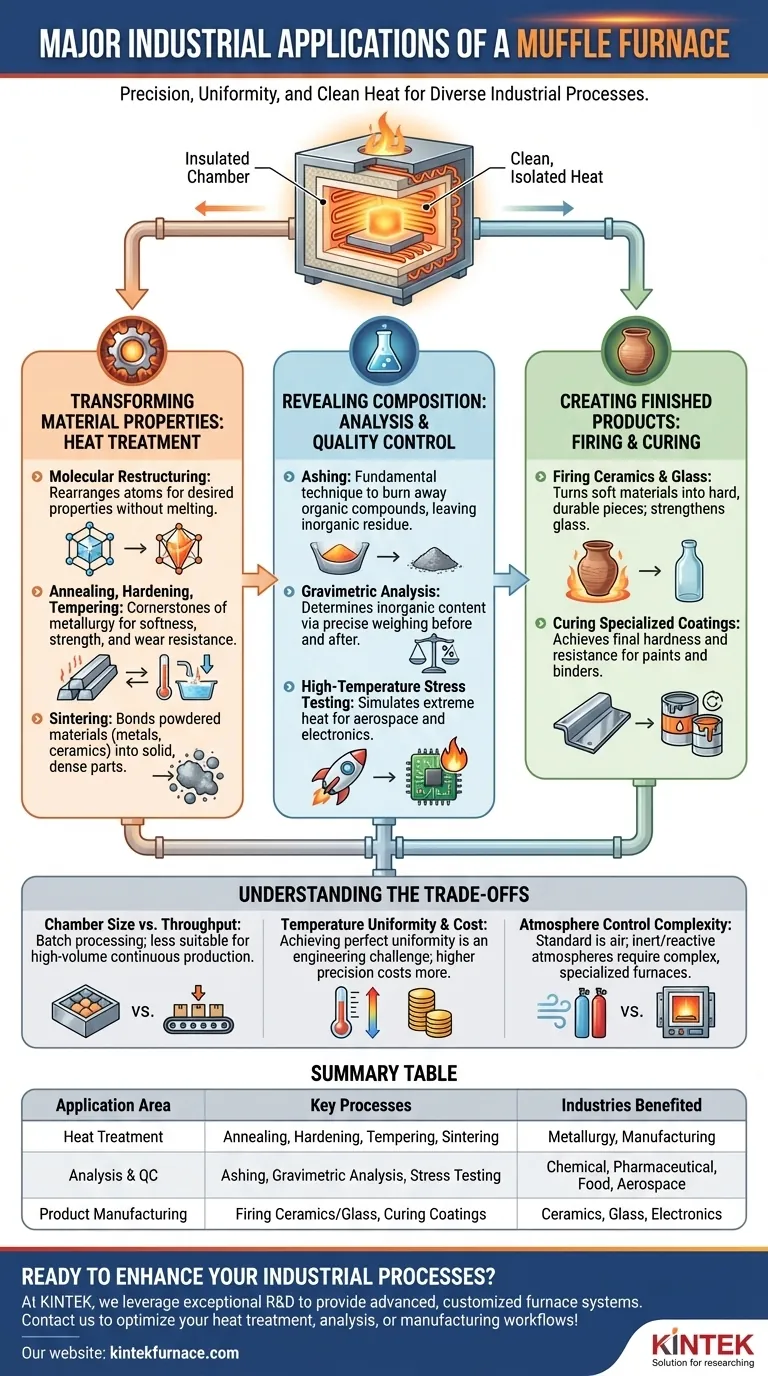

Transforming Material Properties: Heat Treatment

The most common industrial use for muffle furnaces is the heat treatment of materials, particularly metals. This involves heating and cooling a material under controlled conditions to alter its internal microstructure and, therefore, its physical and mechanical properties.

The Principle of Molecular Restructuring

Heat treatment does not melt the material. Instead, it gives the atoms within the material's crystal structure enough energy to rearrange themselves into a more desirable configuration, which becomes locked in upon cooling.

Annealing, Hardening, and Tempering

These are the cornerstones of metallurgy. A furnace is used to anneal metals, making them softer and more workable. Conversely, it can be used for hardening by heating and then rapidly cooling (quenching) a part to increase its strength and wear resistance, followed by tempering to reduce brittleness.

Sintering Powders into Solids

Muffle furnaces are critical for sintering, a process used for both metals and ceramics. Powdered materials are heated to a temperature below their melting point, causing the particles to bond and fuse into a solid, coherent mass with desired density and strength.

Revealing Composition: Analysis and Quality Control

When the goal is to understand what a material is made of, a muffle furnace is an essential analytical tool. It uses heat to break down samples for quantitative analysis.

The Critical Role of Ashing

In chemical, pharmaceutical, and food industries, ashing is a fundamental technique. A sample is placed in the furnace and heated until all organic and volatile compounds burn away, leaving only the non-combustible inorganic residue (ash).

Gravimetric Analysis for Quality

By weighing the sample before and after ashing, analysts can precisely determine its inorganic content. This is crucial for quality control in food (mineral content), coal (ash content), and cement production.

High-Temperature Stress Testing

In industries like aerospace and electronics, components must withstand extreme conditions. Muffle furnaces are used to simulate intense heat, testing the flame retardancy of materials or the operational integrity of circuit boards to ensure they meet stringent safety and reliability standards.

Creating Finished Products: Firing and Curing

Beyond modification and analysis, muffle furnaces are directly involved in the manufacturing of certain goods. The controlled heat provides the necessary energy for chemical and physical transformations.

Firing Ceramics and Glass

The process of firing is what turns a soft clay object into a hard, durable ceramic piece. The furnace's uniform heat ensures the part is cured evenly, preventing cracks and weaknesses. Similar processes are used in glass manufacturing to strengthen or shape products.

Curing Specialized Coatings

Certain high-performance paints, coatings, and binders require a thermal curing process to achieve their final hardness and chemical resistance. A muffle furnace provides the consistent, clean environment needed for these reactions to occur properly.

Understanding the Trade-offs

While incredibly versatile, a muffle furnace is not a universal solution. Understanding its limitations is key to using it effectively.

Chamber Size vs. Throughput

Muffle furnaces are fundamentally batch processors. Their chamber size limits the volume of material that can be processed at one time, making them less suitable for high-volume, continuous production lines compared to tunnel kilns.

Temperature Uniformity and Cost

Achieving perfect temperature uniformity throughout the chamber is an engineering challenge. Higher-specification furnaces with advanced controllers and multiple heating zones provide better uniformity but come at a significantly higher cost.

Atmosphere Control Complexity

A standard muffle furnace operates with an air atmosphere. If a process requires an inert (e.g., nitrogen, argon) or reactive atmosphere to prevent oxidation, a specialized and more complex furnace with gas-tight seals and input ports is necessary.

Making the Right Choice for Your Goal

The ideal application of a muffle furnace depends entirely on the industrial objective.

- If your primary focus is metallurgical processing: You need precise temperature control, programmable heating/cooling ramps, and potentially an inert atmosphere for sensitive alloys.

- If your primary focus is analytical chemistry (ashing): Your priority is ensuring complete combustion of organic matter, temperature stability, and preventing cross-contamination between samples.

- If your primary focus is material testing or R&D: Versatility is key, so look for a furnace with a wide temperature range, programmable cycles, and robust construction to handle diverse materials.

Ultimately, the muffle furnace serves as a fundamental tool for manipulating and understanding materials where controlled, clean heat is the critical parameter.

Summary Table:

| Application Area | Key Processes | Industries Benefited |

|---|---|---|

| Heat Treatment | Annealing, Hardening, Tempering, Sintering | Metallurgy, Manufacturing |

| Analysis & Quality Control | Ashing, Gravimetric Analysis, Stress Testing | Chemical, Pharmaceutical, Food, Aerospace |

| Product Manufacturing | Firing Ceramics/Glass, Curing Coatings | Ceramics, Glass, Electronics |

Ready to enhance your industrial processes with tailored high-temperature solutions?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnace systems for diverse laboratories and industries. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization capabilities to precisely meet your unique experimental and production needs.

Contact us today to discuss how our solutions can optimize your heat treatment, analysis, or manufacturing workflows!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites