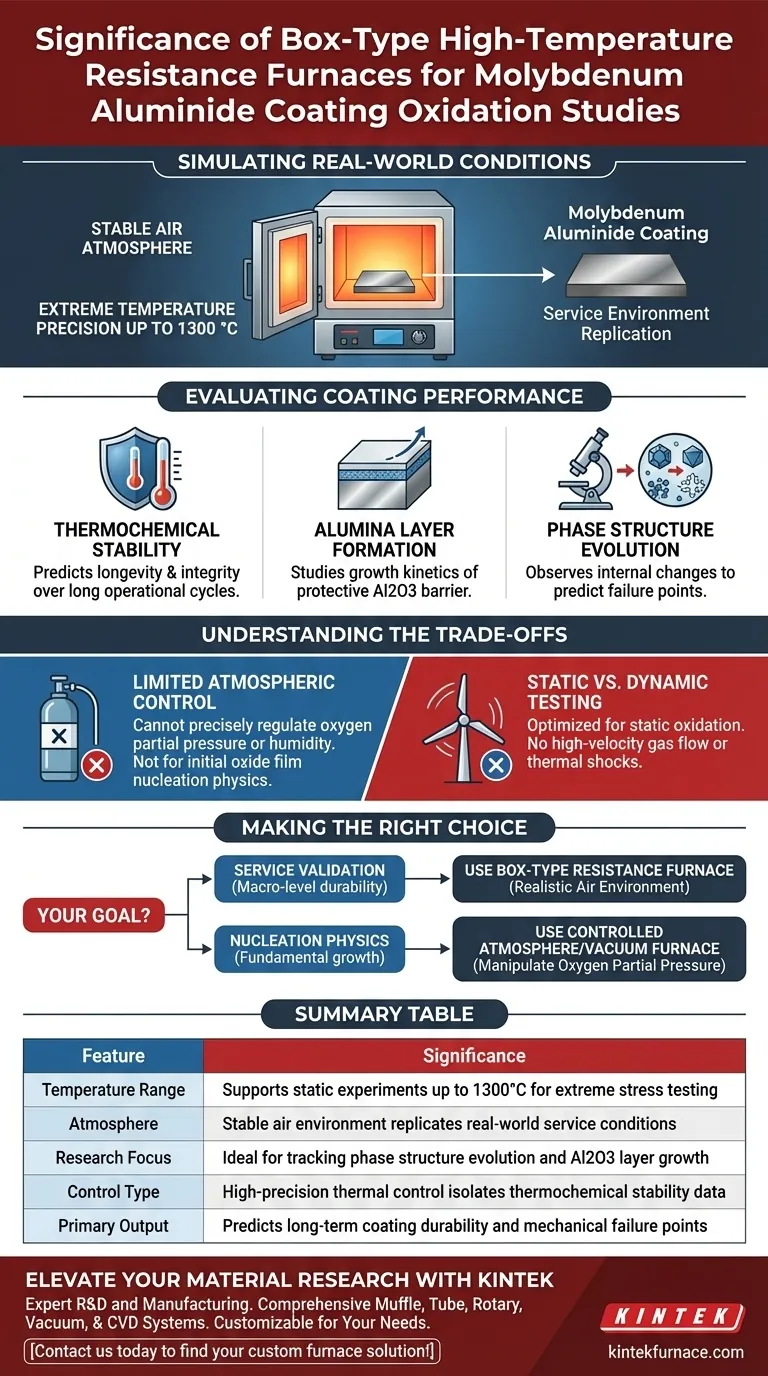

The primary significance of using a box-type high-temperature resistance furnace is its ability to accurately simulate the static oxidation conditions of a coating's actual service environment. By maintaining a stable air atmosphere at extreme temperatures up to 1300 °C, researchers can rigorously test the thermochemical limits of molybdenum aluminide.

This apparatus provides the precise thermal control necessary to isolate the formation of protective alumina (Al2O3) layers and track the phase structure evolution within the coating over time.

Simulating Real-World Conditions

Replicating the Service Environment

The box-type furnace is designed to create a stable air atmosphere.

Unlike controlled atmosphere furnaces that manipulate gas mixtures, this setup exposes the coating to the same oxygen-rich environment it will encounter during actual operation. This is essential for validating how the material behaves outside of theoretical, vacuum-sealed conditions.

Extreme Temperature Precision

Testing molybdenum aluminide coatings requires subjecting them to thermal extremes.

This specific furnace type allows for static experiments at temperatures as high as 1300 °C. Maintaining this heat level with high precision is required to accelerate oxidation processes and stress-test the material's durability.

Evaluating Coating Performance

Assessing Thermochemical Stability

The primary goal of these experiments is to determine the coating's longevity.

By subjecting the sample to sustained high heat, researchers can evaluate the thermochemical stability of the molybdenum aluminide. This data predicts whether the coating will degrade or maintain its integrity over long operational cycles.

Observing Alumina Layer Formation

The effectiveness of a molybdenum aluminide coating relies on its ability to grow a protective oxide scale.

The furnace facilitates the study of how the protective alumina (Al2O3) layer forms and thickens. Understanding the growth kinetics of this layer is vital, as it serves as the primary barrier against further oxidation.

Studying Phase Structure Evolution

Heat causes the internal structure of the coating to change.

Using this furnace allows scientists to observe the phase structure evolution within the coating. Identifying how these phases transform at 1300 °C helps engineers predict mechanical failure points or changes in material properties.

Understanding the Trade-offs

Limited Atmospheric Control

While excellent for simulating air oxidation, the box-type furnace lacks the versatility of vacuum induction or controlled atmosphere furnaces.

It cannot precisely regulate oxygen partial pressure or humidity. If your goal is to study the specific physics of initial oxide film nucleation (such as the transition from amorphous to crystalline γ-Al2O3), a controlled atmosphere furnace is a better tool.

Static vs. Dynamic Testing

The box-type furnace is optimized for static oxidation.

It does not inherently simulate dynamic factors like high-velocity gas flow or thermal cycling shocks found in some engine environments. It provides a baseline for chemical stability rather than a full simulation of mechanical stress.

Making the Right Choice for Your Goal

To select the correct experimental setup, you must define the specific aspect of the coating you wish to analyze.

- If your primary focus is Service Validation: Use the box-type resistance furnace to test how the coating survives and evolves in a standard, high-temperature air environment.

- If your primary focus is Nucleation Physics: Use a controlled atmosphere or vacuum furnace to manipulate oxygen partial pressure and study the fundamental growth of oxide films from the melt.

By choosing the box-type furnace, you are prioritizing the evaluation of macro-level durability and chemical resilience in a realistic operating atmosphere.

Summary Table:

| Feature | Significance for Molybdenum Aluminide Testing |

|---|---|

| Temperature Range | Supports static experiments up to 1300°C for extreme stress testing |

| Atmosphere | Stable air environment replicates real-world service conditions |

| Research Focus | Ideal for tracking phase structure evolution and Al2O3 layer growth |

| Control Type | High-precision thermal control isolates thermochemical stability data |

| Primary Output | Predicts long-term coating durability and mechanical failure points |

Elevate Your Material Research with KINTEK

Ready to achieve unmatched precision in your high-temperature oxidation studies? Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are testing molybdenum aluminide coatings or developing next-generation alloys, our lab high-temp furnaces are fully customizable to meet your unique thermal processing needs.

Contact us today to find your custom furnace solution!

Visual Guide

References

- Jurica Filipovic, Matthias Oechsner. Thermokinetic Modeling Approach for Aluminide Diffusion Coatings on Molybdenum Substrates. DOI: 10.1002/adem.202500293

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition

- What is the general structure of a muffle furnace? Discover Its Precision Engineering

- How does an industrial box resistance furnace facilitate the calcination of Mn-Zn ferrite? Boost Process Stability

- What is the temperature range of a box furnace? Key Factors for Your Application

- What critical support does an industrial muffle furnace provide in mineral dielectric evolution? Real-Time Insights

- What are some key applications of muffle furnaces? Unlock Precision and Purity in High-Temp Processes

- How does an industrial muffle furnace achieve precise temperature control? Mastering CCCM Heat Treatment Precision

- What is the function of high-temperature furnaces in biogenic hydroxyapatite conversion? Achieve High-Purity Biomaterials