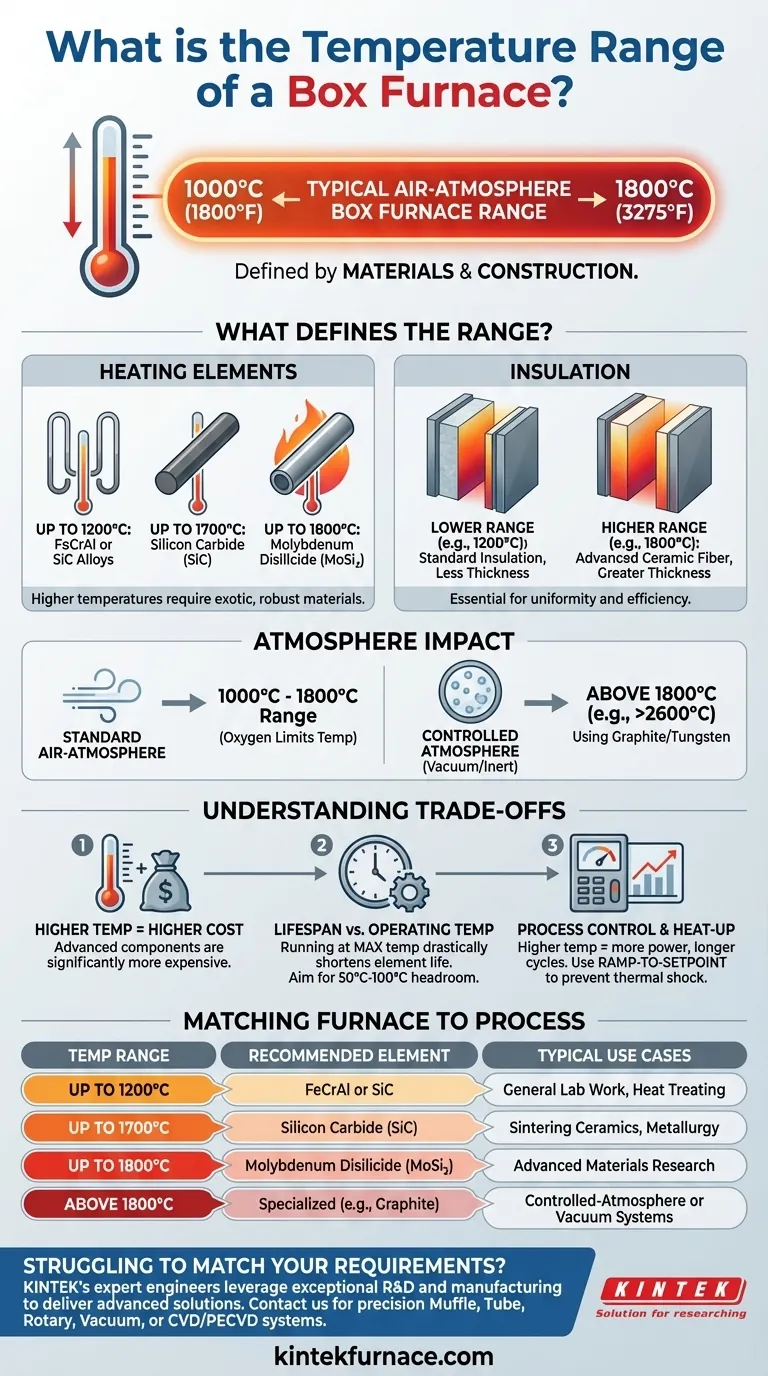

In short, a standard air-atmosphere box furnace typically operates within a temperature range of 1000°C to 1800°C (1800°F to 3275°F). While some units are designed for lower ranges, the most common high-temperature models fall within these bounds. The specific maximum temperature is not universal but is a direct function of the furnace's materials and construction.

The term "box furnace" describes a category of equipment, not a single specification. The advertised temperature range is fundamentally dictated by the materials used for its heating elements and internal insulation. Understanding this relationship is key to selecting the correct tool for your thermal process.

What Defines a Furnace's Temperature Range?

A furnace's ability to reach and sustain a specific temperature is not an arbitrary number. It is a result of deliberate engineering choices balancing performance, cost, and lifespan.

The Role of Heating Elements

The material used for the heating elements is the primary factor determining the maximum achievable temperature. Different materials have different limits before they degrade or fail, especially in an oxygen-rich air atmosphere.

Furnaces designed for higher temperatures (e.g., 1700°C - 1800°C) must use more exotic and robust elements, such as those made from molybdenum disilicide (MoSi₂). Lower-range furnaces may use more common materials like silicon carbide (SiC) or iron-chrome-aluminum (FeCrAl) alloys.

The Importance of Insulation

The insulation material must withstand the extreme heat generated by the elements. High-purity refractory ceramic fiber and firebrick are used to line the chamber, preventing heat loss and protecting the furnace's external structure.

A furnace rated for 1800°C will have a more advanced and thicker insulation package than a 1200°C model. This ensures temperature uniformity and operational efficiency.

Standard Air vs. Controlled Atmosphere

The typical 1000°C to 1800°C range applies specifically to air-atmosphere box furnaces. The presence of oxygen limits the maximum temperature of even the best heating elements.

Specialized units, like vacuum furnaces, operate without air. By removing the oxygen, these furnaces can utilize different heating elements (like graphite or tungsten) to reach far higher temperatures, sometimes in excess of 2600°C, for highly specialized applications.

Understanding the Trade-offs

Selecting a furnace involves more than just finding one that meets your maximum temperature requirement. You must consider the following practical trade-offs.

Higher Temperature Equals Higher Cost

There is a direct and significant correlation between a furnace's maximum temperature and its price. The specialized heating elements and advanced insulation required for 1800°C operation are substantially more expensive than the components used in a 1400°C model.

Element Lifespan and Operating Temperature

Consistently operating a furnace at its absolute maximum rated temperature will drastically shorten the lifespan of its heating elements. For longevity and reliability, it is wise to select a furnace with a maximum temperature rating at least 50°C to 100°C higher than your typical operating temperature.

Process Control and Heat-Up Time

Higher-temperature furnaces require more power and may have longer heat-up cycles. Modern units often include programmable controllers with a ramp-to-setpoint feature, allowing you to control the rate of temperature increase. This protects both the furnace and the material being processed from thermal shock.

Matching the Furnace to Your Process

Choosing the right furnace requires a clear understanding of your application's temperature demands.

- If your primary focus is general lab work or heat treating below 1200°C: A standard, cost-effective furnace with robust FeCrAl or SiC elements is an excellent choice.

- If your primary focus is sintering certain ceramics or metallurgy up to 1700°C: You need a high-performance furnace, likely with silicon carbide (SiC) elements and superior insulation.

- If your primary focus is advanced materials research near 1800°C: Your only option is a top-tier furnace equipped with molybdenum disilicide (MoSi₂) elements and the best available insulation.

- If your primary focus is processing above 1800°C: A standard air-atmosphere box furnace is unsuitable, and you must investigate specialized controlled-atmosphere or vacuum furnace systems.

By understanding the relationship between your temperature needs and the furnace's core components, you can select a tool that is both effective and economical for your specific application.

Summary Table:

| Application Temperature Range | Recommended Heating Element | Typical Use Cases |

|---|---|---|

| Up to 1200°C | FeCrAl or SiC | General lab work, heat treating |

| Up to 1700°C | Silicon Carbide (SiC) | Sintering ceramics, metallurgy |

| Up to 1800°C | Molybdenum Disilicide (MoSi₂) | Advanced materials research |

| Above 1800°C | Specialized (e.g., Graphite) | Controlled-atmosphere or vacuum systems |

Struggling to match a furnace to your exact temperature and process requirements? KINTEK's expert engineers leverage exceptional R&D and in-house manufacturing to deliver advanced high-temperature furnace solutions. Whether you need a standard Muffle Furnace or a deeply customized Tube, Rotary, Vacuum, or CVD/PECVD system, we design for precision, durability, and your unique experimental needs.

Contact our thermal experts today for a consultation and ensure your lab has the right tool for the job.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision