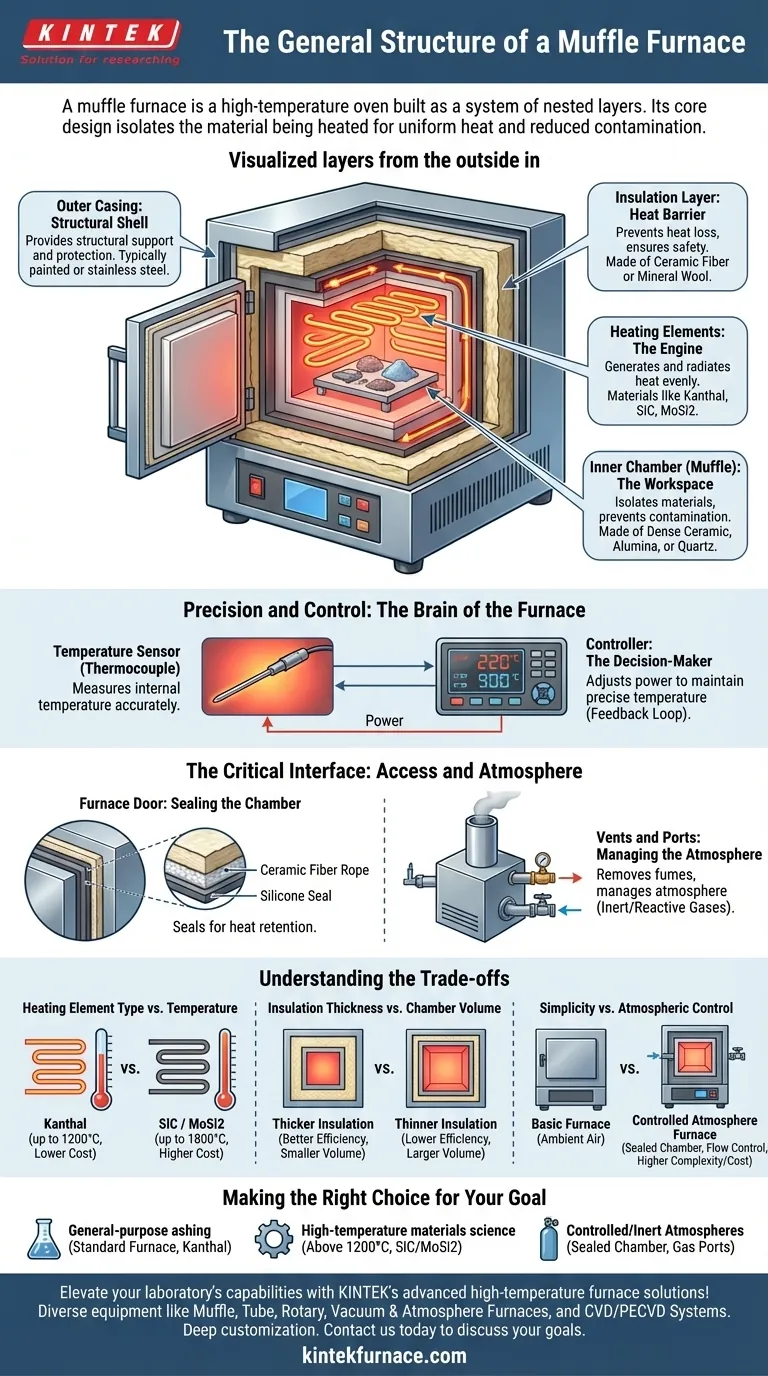

At its core, a muffle furnace is a high-temperature oven built as a system of nested layers. Its structure consists of a protective outer casing, a thick insulation layer, powerful heating elements, and a central inner chamber—the "muffle"—that holds the material. This design isolates the material being heated from direct contact with the flame or heating elements, ensuring uniform heat and preventing contamination.

The essential insight is that a muffle furnace isn't just a hot box. It's a precisely engineered system where each component—from the outer shell to the inner controller—serves a specific purpose: to generate, contain, and control extreme heat with precision, efficiency, and safety.

The Core Components: A System of Layers

Understanding a muffle furnace is best done by thinking from the outside in. Each layer builds upon the last to create a stable, high-temperature environment.

The Outer Casing: The Structural Shell

The outermost layer is a rigid casing, typically fabricated from painted or stainless steel. Its primary job is to provide structural support and protect the internal components from the external environment. This shell is what gives the furnace its familiar box-like shape.

The Insulation Layer: The Heat Barrier

Between the outer casing and the inner workings lies a thick layer of insulation. This is commonly made from high-performance materials like ceramic fiber or mineral wool. This layer is critical for two reasons: it prevents immense heat loss, making the furnace energy-efficient, and it keeps the outer casing at a safe temperature for operators.

The Heating Elements: The Engine

The heat itself is generated by powerful heating elements. These are made from high-resistance materials such as Kanthal (nichrome), silicon carbide (SiC), or molybdenum disilicide (MoSi2). They are strategically placed around the inner chamber to radiate heat evenly, eliminating hot spots and ensuring uniform temperature distribution across the sample.

The Inner Chamber (The Muffle): The Workspace

This is the heart of the furnace and the origin of its name. The muffle is the isolated chamber where materials are placed. It is constructed from refractory materials like dense ceramic, alumina, or quartz, which can withstand extreme thermal shock.

Crucially, the muffle separates the workload from the heating elements. This prevents any byproducts from the heating elements from contaminating the sample and protects the elements from any fumes or spatter from the sample.

Precision and Control: The Brain of the Furnace

Generating heat is only half the battle. Controlling it is what makes a muffle furnace a scientific instrument.

Temperature Sensors (Thermocouples): The Eyes and Ears

A thermocouple is a sensor that extends into the heating chamber to measure the internal temperature accurately. It acts as the furnace's sensory input, constantly relaying real-time temperature data back to the controller.

The Controller: The Decision-Maker

The temperature controller is the furnace's brain. It receives data from the thermocouple, compares it to the user's desired temperature (the setpoint), and precisely adjusts the power sent to the heating elements. This constant feedback loop allows for maintaining temperatures with incredible accuracy, often within a few degrees.

The Critical Interface: Access and Atmosphere

The final pieces of the structure govern how the user interacts with the furnace and how the internal atmosphere is managed.

The Furnace Door: Sealing the Chamber

The door is more than just a cover; it's a critical sealing component. High-quality furnaces feature multi-layer seals, often with an inner ceramic fiber rope for high-temperature resilience and an outer silicone seal. Sophisticated models may even include a water-cooled door frame to prolong the life of the seals during extreme temperature operation.

Vents and Ports: Managing the Atmosphere

Most furnaces include an exhaust port or ventilation system. This allows for the safe removal of fumes, moisture, or other gases released during the heating process. In more advanced models, dedicated intake and exhaust ports allow users to introduce specific gases to create a controlled, inert, or reactive atmosphere inside the chamber.

Understanding the Trade-offs

Selecting or using a muffle furnace involves balancing competing factors.

Heating Element Type vs. Temperature

The choice of heating element material directly dictates the furnace's maximum operating temperature and lifespan. Kanthal elements are common and cost-effective for temperatures up to 1200°C, while SiC or MoSi2 elements are required for higher temperatures (up to 1800°C) but come at a higher cost.

Insulation Thickness vs. Chamber Volume

Thicker, higher-quality insulation improves energy efficiency and temperature stability. However, this often comes at the expense of usable internal chamber volume for a given external footprint.

Simplicity vs. Atmospheric Control

A basic furnace simply heats in the ambient air and vents fumes. A furnace designed for controlled atmosphere work requires a fully sealed chamber, gas-tight ports, and flow control systems, which adds significant complexity and cost to the design.

Making the Right Choice for Your Goal

Your application determines which structural features are most important.

- If your primary focus is general-purpose ashing or simple heat treating: A standard furnace with Kanthal elements and a basic digital controller is a reliable and cost-effective choice.

- If your primary focus is high-temperature materials science (above 1200°C): Prioritize a furnace built with SiC or MoSi2 heating elements and superior multi-layer insulation.

- If your primary focus is working with controlled or inert atmospheres: You must select a model specifically designed with a sealed chamber and dedicated gas inlet and outlet ports.

By understanding how these structural components function as a system, you are empowered to select the right instrument and operate it with precision and confidence.

Summary Table:

| Component | Function | Common Materials |

|---|---|---|

| Outer Casing | Provides structural support and protection | Painted or stainless steel |

| Insulation Layer | Prevents heat loss and ensures safety | Ceramic fiber, mineral wool |

| Heating Elements | Generates and radiates heat evenly | Kanthal, silicon carbide, molybdenum disilicide |

| Inner Chamber (Muffle) | Holds materials, prevents contamination | Dense ceramic, alumina, quartz |

| Temperature Sensors | Measures internal temperature accurately | Thermocouples |

| Controller | Adjusts power to maintain precise temperature | Digital temperature controllers |

| Furnace Door | Seals the chamber for heat retention | Ceramic fiber rope, silicone seals |

| Vents and Ports | Manages atmosphere and removes fumes | Exhaust ports, gas inlet/outlet systems |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering enhanced efficiency, safety, and performance. Contact us today to discuss how we can support your specific goals and drive innovation in your work!

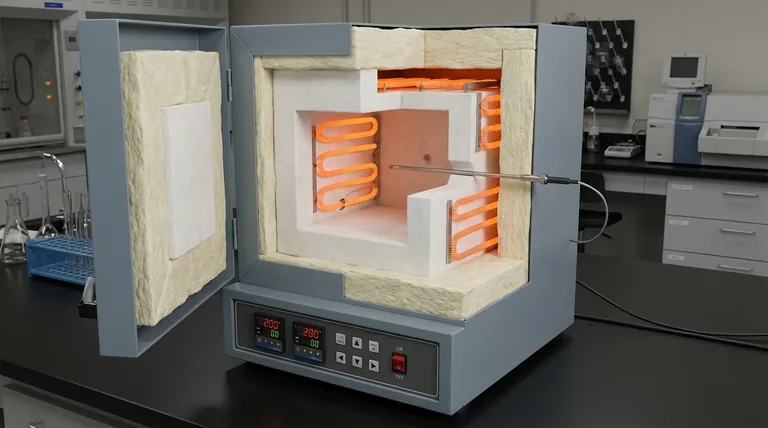

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?