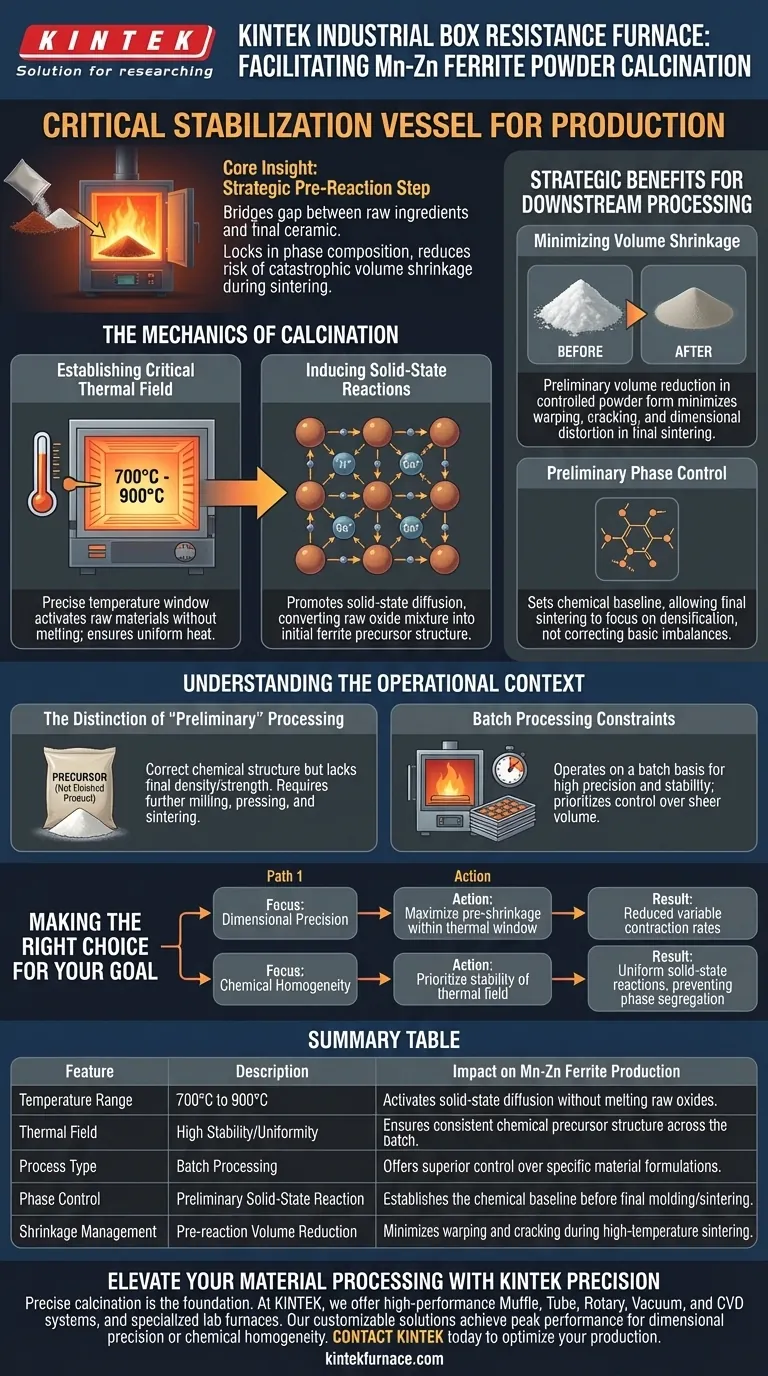

An industrial box resistance furnace functions as a critical stabilization vessel for the production of Mn-Zn ferrite powders. It facilitates calcination by establishing a precise, stable thermal field between 700 and 900 °C, which triggers preliminary solid-state reactions among raw oxides to create a ferrite precursor structure.

Core Insight: Calcination is a strategic pre-reaction step that bridges the gap between raw ingredients and the final ceramic. By locking in the phase composition and pre-reacting the powder in a box resistance furnace, you significantly reduce the risk of catastrophic volume shrinkage during the subsequent high-temperature sintering stage.

The Mechanics of Calcination

Establishing the Critical Thermal Field

The primary function of the box resistance furnace is to maintain a specific temperature window, strictly between 700 and 900 °C.

This range is energetic enough to activate the raw materials but low enough to avoid melting or full densification. The stability of this thermal field ensures that the entire batch of powder receives uniform heat energy.

Inducing Solid-State Reactions

Within this heated environment, the furnace facilitates the interaction of raw oxides.

Rather than melting the materials, the heat promotes solid-state diffusion. This process moves ions between particles, converting the mixture of raw oxides into the initial ferrite precursor structure required for magnetic applications.

Strategic Benefits for Downstream Processing

Minimizing Volume Shrinkage

A major challenge in ferrite manufacturing is the physical contraction of the material during final processing.

The calcination step in the box furnace forces the material to undergo a preliminary volume reduction. By handling this shrinkage early in a controlled powder form, you minimize the risk of warping, cracking, or dimensional distortion during the final high-temperature sintering of the molded part.

Preliminary Phase Control

The furnace allows engineers to dictate the material's phase composition before it is ever molded.

By controlling the thermal exposure in the box furnace, you set the chemical baseline of the material. This preliminary control ensures that the final sintering stage focuses on densification rather than struggling to correct basic chemical imbalances.

Understanding the Operational Context

The Distinction of "Preliminary" Processing

It is vital to recognize that the output of this furnace is a precursor, not a finished product.

The material exiting the box furnace has the correct chemical structure but lacks the density and mechanical strength of the final ferrite. It must still undergo milling, pressing, and a final high-temperature sintering cycle to become a functional component.

Batch Processing Constraints

As a "box" type furnace, this equipment typically operates on a batch basis rather than a continuous flow.

This ensures high precision and stability for specific formulations but may limit throughput speed compared to continuous tunnel kilns. It is an equipment choice that prioritizes control over sheer volume.

Making the Right Choice for Your Goal

To maximize the effectiveness of your Mn-Zn ferrite production, align your furnace settings with your specific processing needs:

- If your primary focus is dimensional precision: Ensure the calcination process fully utilizes the thermal window to maximize pre-shrinkage, reducing the variable contraction rates during final sintering.

- If your primary focus is chemical homogeneity: Prioritize the stability of the thermal field to ensure uniform solid-state reactions across the entire batch, preventing phase segregation.

Effective calcination is the foundation of high-performance ferrite ceramics, turning volatile raw oxides into a stable, predictable manufacturing resource.

Summary Table:

| Feature | Description | Impact on Mn-Zn Ferrite Production |

|---|---|---|

| Temperature Range | 700°C to 900°C | Activates solid-state diffusion without melting raw oxides. |

| Thermal Field | High Stability/Uniformity | Ensures consistent chemical precursor structure across the batch. |

| Process Type | Batch Processing | Offers superior control over specific material formulations. |

| Phase Control | Preliminary Solid-State Reaction | Establishes the chemical baseline before final molding/sintering. |

| Shrinkage Management | Pre-reaction Volume Reduction | Minimizes warping and cracking during high-temperature sintering. |

Elevate Your Material Processing with KINTEK Precision

Precise calcination is the foundation of high-performance Mn-Zn ferrite production. At KINTEK, we understand that thermal stability and customization are critical to your success. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temperature furnaces tailored to your unique specifications.

Whether you are focusing on dimensional precision or chemical homogeneity, our customizable industrial furnaces ensure your materials achieve peak performance. Contact KINTEK today to discuss your thermal processing needs and see how our expertise can optimize your production outcomes.

Visual Guide

References

- A. Faeghinia. Effects of sintering and pressing conditions on the properties of manganese ferrite. DOI: 10.53063/synsint.2025.53260

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the use of a muffle furnace in a laboratory? Achieve Precise High-Temperature Transformations

- How does the muffle design contribute to furnace performance? Enhance Purity, Uniformity, and Efficiency

- What is a muffle furnace and how does it relate to laboratory furnaces? Discover Its Key Benefits for Your Lab

- What are some specific applications of muffle furnaces? Unlock Precision in Heat Treatment and Analysis

- How should materials like alkaline substances or Pyrex glass be handled in the muffle furnace? Ensure Safety and Longevity

- What role do auxiliary equipment like fans and sprayers play in a box furnace? Enhance Precision and Efficiency in Heat Treatment

- What are the key considerations when selecting a muffle furnace? Ensure Optimal Performance for Your Lab

- What role does a box muffle furnace play in the calcination of ZnO? Master Nanoparticle Crystal Engineering