To safely handle specific materials in a muffle furnace, you must use protective barriers to prevent irreversible damage to the furnace chamber. For alkaline substances, place your crucible on a refractory plate to shield the furnace floor from chemical corrosion. For Pyrex glass, wrap open ends or small items in aluminum foil to act as a release agent and prevent the glass from fusing to the furnace surfaces at high temperatures.

The core issue is not the materials themselves, but how they react with the furnace's delicate interior at extreme temperatures. The fundamental solution is to always place a protective, sacrificial barrier between your sample and the furnace floor to prevent chemical corrosion and physical bonding.

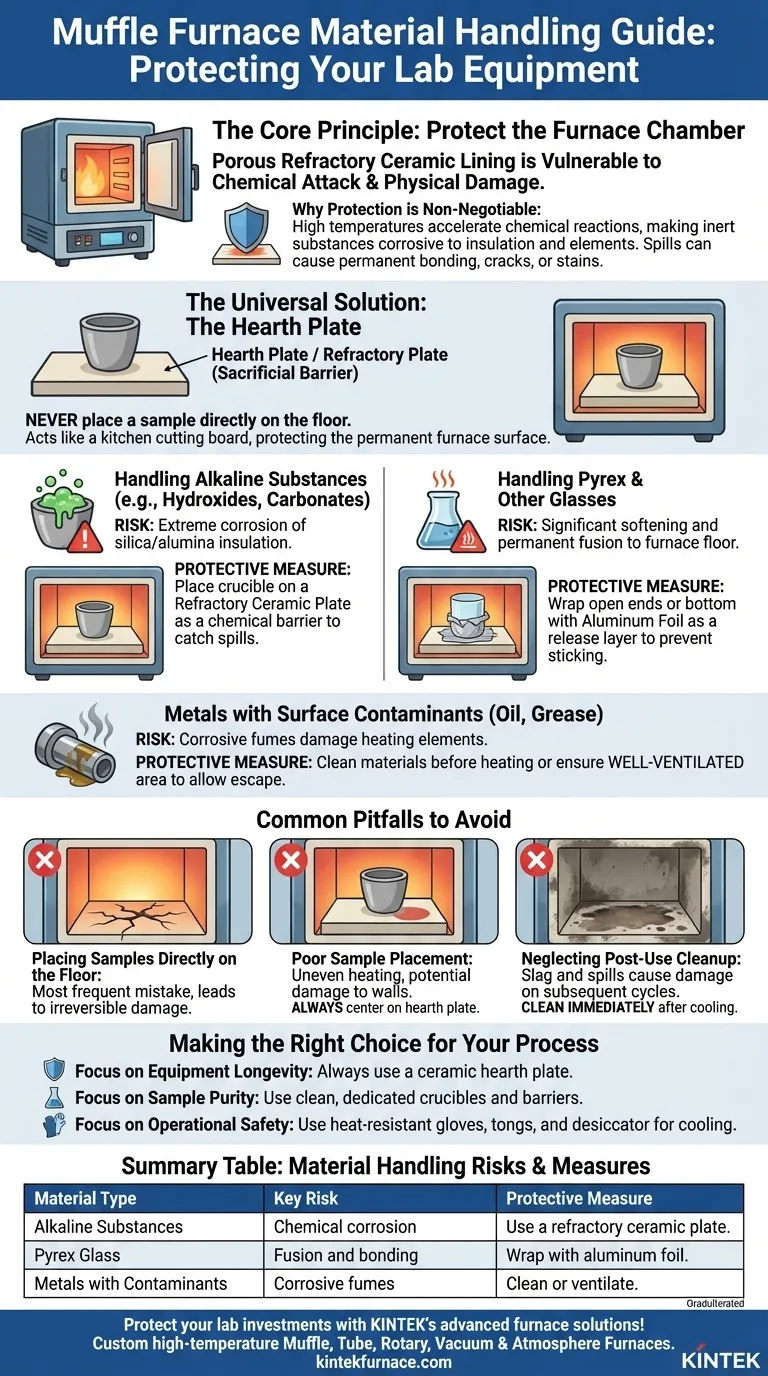

The Core Principle: Protecting the Furnace Chamber

The interior of a muffle furnace is typically lined with a porous refractory ceramic. While durable against heat, this material is highly susceptible to chemical attack and physical damage, which can be costly and difficult to repair.

Why Protection is Non-Negotiable

At high temperatures, chemical reactions are significantly accelerated. Seemingly inert substances can become highly corrosive, attacking the furnace insulation and heating elements. Spills can seep into the porous floor, causing stains, cracking upon cooling, or bonding permanently to the surface.

The Universal Solution: The Hearth Plate

The most critical practice is to never place a sample directly on the furnace floor. Always use a protective layer, often called a hearth plate or refractory plate.

Think of a hearth plate as a cutting board for your kitchen counter. It is a durable, sacrificial surface that takes the wear, spills, and abuse, protecting the expensive and permanent surface underneath. These plates are typically made of dense, high-alumina ceramic.

Handling Specific, Reactive Materials

Different materials pose different risks. Understanding the specific interaction is key to choosing the right protective measure.

For Alkaline Substances

Alkaline materials (e.g., hydroxides, carbonates) are extremely corrosive to the silica and alumina content found in furnace insulation. Direct contact will etch and degrade the furnace floor.

The standard protocol is to place your crucible on a refractory ceramic plate. This plate acts as a chemical barrier, catching any potential spills or boil-overs and protecting the furnace hearth.

For Pyrex and Other Glasses

Borosilicate glass, such as Pyrex, softens significantly at temperatures achievable in many muffle furnaces. The primary risk is fusion, where the softened glass bonds directly and permanently to the furnace floor or crucible.

To prevent this, wrap the bottom of your glass item or any open ends with aluminum foil. The foil acts as a simple, effective release layer, preventing the glass from sticking as it heats and cools.

For Metals with Surface Contaminants

When heating metals coated in oil, grease, or other volatile substances, these compounds will burn off. The resulting gases can be highly corrosive to the heating elements, significantly shortening their operational lifespan.

If possible, clean materials before heating. If not, ensure the furnace is in a well-ventilated area to allow these corrosive fumes to escape quickly.

Common Pitfalls to Avoid

Mistakes in material handling are the leading cause of premature furnace failure. Avoiding these common errors is essential for ensuring the longevity of your equipment.

Placing Samples Directly on the Floor

This is the most frequent and damaging mistake. Even a small spill can lead to corrosion or create a fused mass that is impossible to remove without damaging the hearth.

Poor Sample Placement

Always place your sample in the center of the hearth plate. This ensures the most even heating and minimizes the risk of radiant heat overshooting the sample and damaging the furnace walls or door. It also keeps your sample away from direct contact with the heating elements.

Neglecting Post-Use Cleanup

After a run, inspect the furnace interior. Any slag, metal oxides, or spilled material should be removed immediately after the furnace has cooled. If left, these spills can cause damage on subsequent heat cycles.

Making the Right Choice for Your Process

Your specific handling procedure should be guided by your primary goal, whether it's equipment longevity, sample purity, or safety.

- If your primary focus is protecting the furnace: Always use a ceramic hearth plate, regardless of the material you are processing. It is the single best investment to extend the life of your furnace.

- If your primary focus is preventing sample contamination: Use clean, dedicated crucibles for each material type and ensure any protective barriers, like foil, are clean.

- If your primary focus is operational safety: Always use heat-resistant gloves and tongs for handling. Place heated crucibles in a dedicated desiccator to cool, which prevents thermal shock to the crucible and protects it from atmospheric moisture.

Proper material handling transforms your furnace from a simple appliance into a reliable and long-lasting scientific instrument.

Summary Table:

| Material Type | Key Risk | Protective Measure |

|---|---|---|

| Alkaline Substances | Chemical corrosion of furnace floor | Use a refractory ceramic plate as a barrier |

| Pyrex Glass | Fusion and bonding to furnace surfaces | Wrap with aluminum foil as a release layer |

| Metals with Contaminants | Corrosive fumes damaging heating elements | Clean before heating or ensure ventilation |

Protect your lab investments with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, enhancing safety and efficiency. Contact us today to discuss how we can support your research and extend equipment longevity!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production