At its core, a muffle is far more than just the inner chamber of a furnace. It is a precisely engineered component that creates a thermally isolated, chemically non-reactive, and uniformly heated environment. By separating the heating elements from the processing area, the muffle's design is the primary factor determining the purity, accuracy, and repeatability of any high-temperature application.

The fundamental purpose of a muffle is to act as a barrier. Its design choices—from material and geometry to sealing mechanisms—directly dictate the furnace's ability to protect the sample from contamination while ensuring precise and even heat distribution.

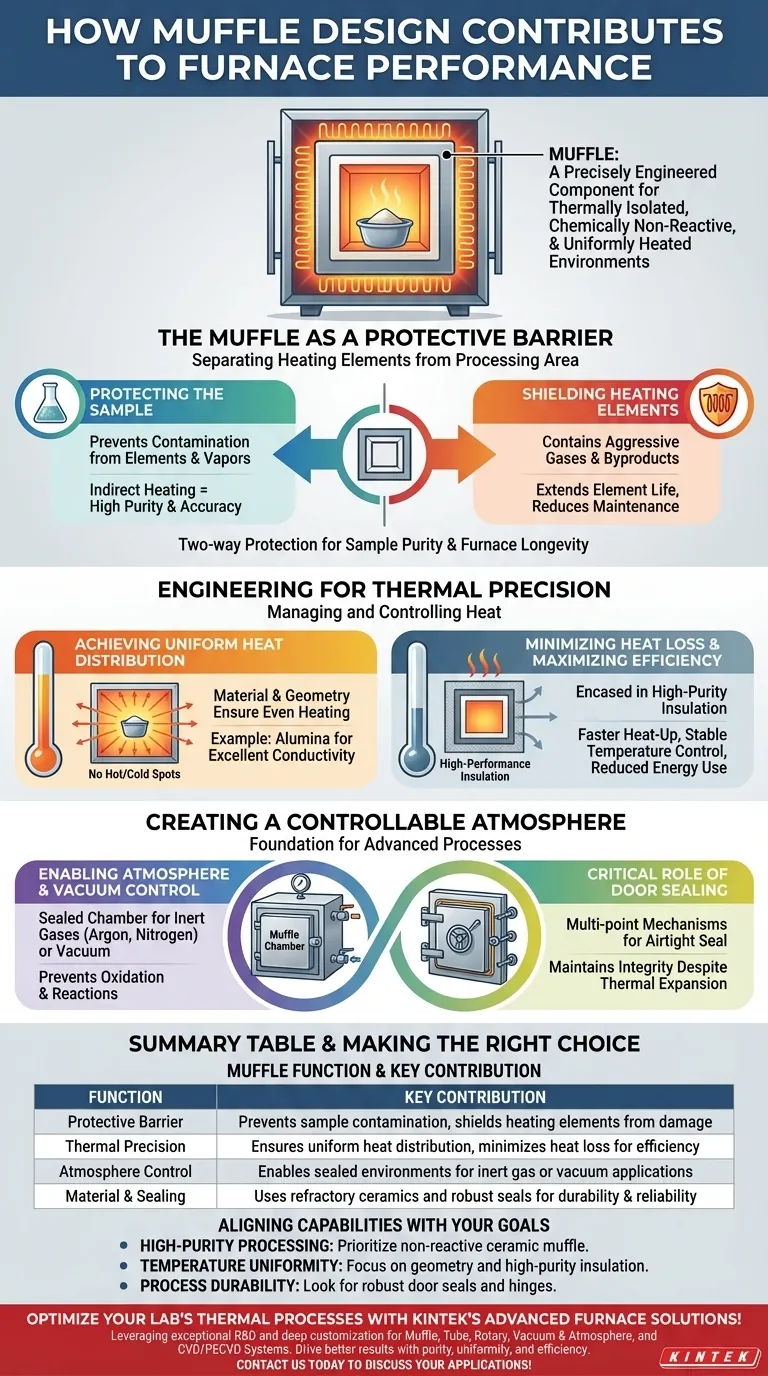

The Muffle as a Protective Barrier

The most fundamental contribution of the muffle is creating separation. This two-way protection is critical for both the sample being processed and the furnace itself.

Protecting the Sample from Contamination

The heating elements, which reach extreme temperatures, can shed microscopic particles or release vapors. The muffle forms an impassable physical barrier between these elements and your sample.

This indirect heating method is essential for applications where even trace amounts of contamination could compromise the results, such as in materials science research or analytical chemistry.

Shielding Heating Elements from Damage

Conversely, many thermal processes release aggressive gases, vapors, or byproducts. These emissions can corrode or degrade the expensive and sensitive heating elements.

The muffle contains these byproducts, significantly extending the life of the heating elements and reducing furnace maintenance and downtime.

Engineering for Thermal Precision

Beyond just separation, the muffle's design is engineered to manage and control heat with a high degree of precision, which is a cornerstone of furnace performance.

Achieving Uniform Heat Distribution

The material and geometry of the muffle are chosen to absorb and radiate heat evenly throughout the chamber. This prevents "hot spots" and "cold spots" that can lead to inconsistent processing.

Materials like alumina are selected for their excellent thermal conductivity and stability at high temperatures, ensuring the entire sample experiences the same thermal conditions.

Minimizing Heat Loss and Maximizing Efficiency

The muffle is encased in high-performance insulation, such as high-purity alumina fiber. This insulation minimizes heat loss to the outside environment.

This efficient design not only reduces energy consumption but also contributes to faster heat-up times and more stable temperature control, as the system isn't constantly fighting to replace lost energy.

Understanding the Trade-offs

A muffle furnace's design represents a series of deliberate engineering compromises. Understanding these helps you align the equipment's capabilities with your specific needs.

Material Choice and Chemical Inertness

The muffle is typically made from a refractory ceramic like alumina because it is highly resistant to both extreme heat and chemical attack. This makes it ideal for a wide range of applications.

However, no single material is perfect for every process. The choice of ceramic is a balance between thermal performance, chemical inertness for your specific sample, and cost.

Indirect Heating vs. Ramp Rate

The key benefit of indirect heating is purity and uniformity. The trade-off is that it can sometimes result in slower temperature ramp rates compared to furnaces where elements are directly exposed to the chamber.

For processes requiring maximum purity and precision, this slightly slower heating is a worthwhile compromise.

Sealing Complexity vs. Reliability

Advanced furnaces feature complex door seals, often with multiple layers (e.g., inner ceramic rope, outer silicone ring), cooling jackets, and multi-point locking mechanisms.

This complexity ensures an airtight seal for atmosphere control and safety, but it requires proper operation and maintenance to remain effective over the furnace's lifespan.

Creating a Controllable Atmosphere

For many advanced processes, controlling the gaseous environment inside the furnace is just as important as controlling the temperature.

Enabling Atmosphere and Vacuum Control

The sealed chamber created by the muffle is the foundation for controlled-atmosphere applications.

Features like dedicated vent ports allow for the introduction of inert gases (like argon or nitrogen) or the removal of air to create a vacuum, preventing unwanted oxidation or reactions during processing.

The Critical Role of Door Sealing

A perfect seal is non-negotiable for atmosphere control. The furnace door is a critical point of potential failure.

Designs using double-hinge mechanisms and multi-point handwheel locks ensure the door seals evenly despite the immense thermal expansion and contraction the furnace undergoes. This robust design guarantees the integrity of the internal atmosphere.

Making the Right Choice for Your Process

The muffle's design directly impacts results. By understanding its key functions, you can better match a furnace's capabilities to your goals.

- If your primary focus is high-purity processing: Prioritize a furnace with a high-quality, non-reactive ceramic muffle to ensure complete separation from heating elements.

- If your primary focus is temperature uniformity: Look for designs that emphasize the muffle's geometry and high-purity insulation to guarantee even heat distribution.

- If your primary focus is process durability and longevity: Pay close attention to the muffle material (alumina) and the robust engineering of the door seals and hinges.

Ultimately, understanding the muffle's design empowers you to move beyond simply setting a temperature and instead control the fundamental conditions of your thermal process.

Summary Table:

| Function | Key Contribution |

|---|---|

| Protective Barrier | Prevents sample contamination and shields heating elements from damage |

| Thermal Precision | Ensures uniform heat distribution and minimizes heat loss for efficiency |

| Atmosphere Control | Enables sealed environments for inert gas or vacuum applications |

| Material and Sealing | Uses refractory ceramics and robust seals for durability and reliability |

Optimize your lab's thermal processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for enhanced purity, uniformity, and efficiency. Contact us today to discuss how we can support your specific applications and drive better results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals