Selecting the right muffle furnace is a decision grounded in matching the equipment's core capabilities to the specific demands of your application. The primary factors to evaluate are the required temperature range and uniformity, the physical size of the chamber needed for your samples, and whether your process requires a controlled atmosphere beyond ambient air. These three pillars dictate nearly every other feature, from heating element type to cost.

The goal is not simply to find a furnace that meets a list of specifications. The true challenge is to select a tool that delivers reliable, repeatable results safely and efficiently over its entire operational lifespan, justifying its role as a critical capital investment.

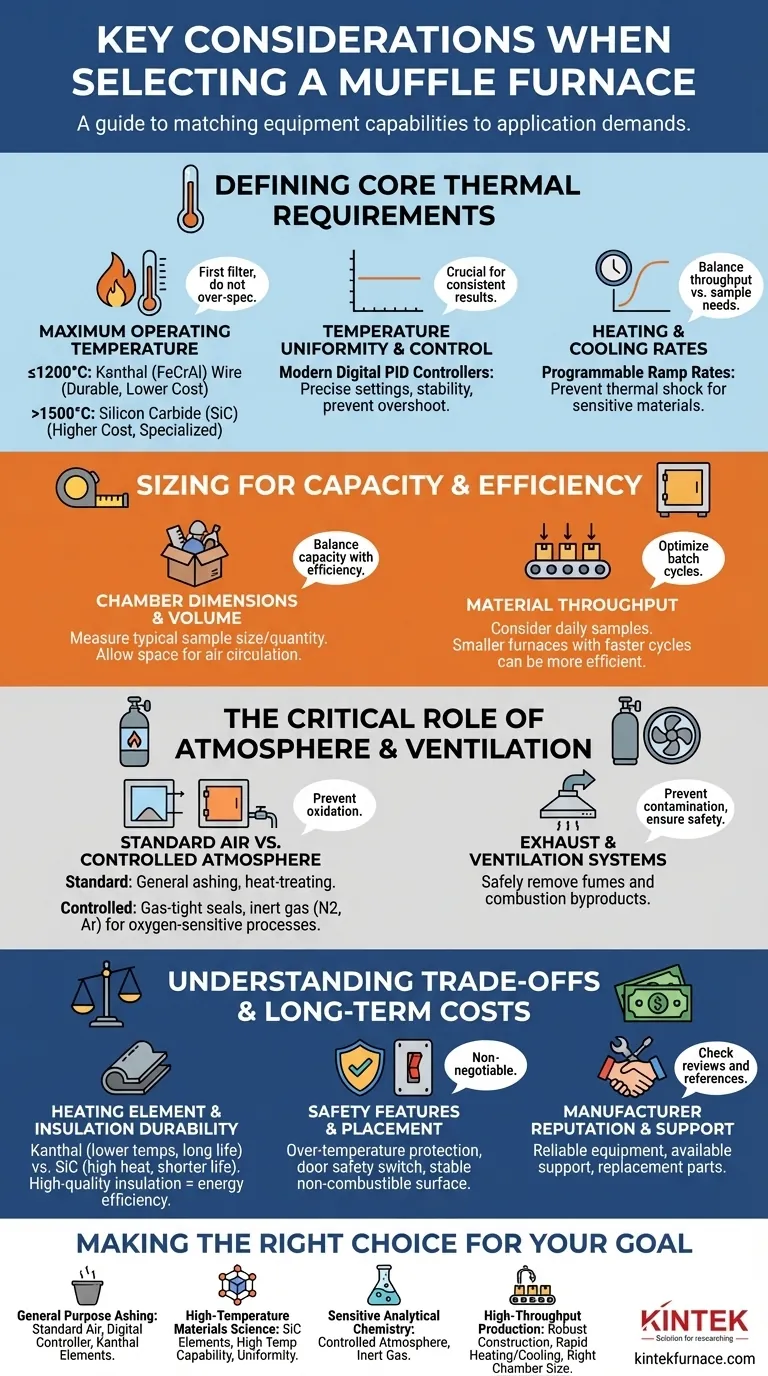

Defining Your Core Thermal Requirements

The single most important function of a muffle furnace is to generate and maintain heat. Your first step is to precisely define the thermal profile your application requires.

Maximum Operating Temperature

Your required maximum operating temperature is the first filter in your selection process. Do not over-spec an unnecessarily high temperature, as this significantly increases cost and energy consumption.

Furnaces operating up to 1100-1200°C typically use durable Kanthal (FeCrAl) wire heating elements. For higher temperatures, often up to 1500°C or more, furnaces require silicon carbide (SiC) or other specialized elements, which are more expensive and can be more brittle.

Temperature Uniformity and Control

For many scientific and quality control applications, temperature uniformity—how consistent the temperature is throughout the entire chamber—is more critical than the maximum temperature itself.

Look for furnaces with modern digital PID (Proportional-Integral-Derivative) controllers. These provide precise temperature settings and stability, preventing overshoot and ensuring your process runs at the exact target temperature. A furnace with poor uniformity can lead to inconsistent results and failed experiments.

Heating and Cooling Rates

The heating rate (ramp rate) determines how quickly the furnace reaches its setpoint. While faster is often better for throughput, some sensitive materials require slow, controlled ramps to prevent thermal shock. Ensure the furnace's controller allows you to program these rates if needed.

Sizing for Capacity and Efficiency

Choosing the correct chamber size is a balance between accommodating your largest samples and maintaining operational efficiency.

Chamber Dimensions and Volume

Measure your typical sample or crucible size and quantity. Select a chamber that can comfortably fit your workload with adequate space for air circulation, which is crucial for uniform heating.

However, an oversized chamber is inefficient. It requires more energy and takes longer to heat, wasting both time and electricity. Choose the smallest size that reliably meets your needs.

Material Throughput

Consider how many samples you need to process per day. A larger furnace may seem like it increases throughput, but a smaller furnace with faster heating and cooling cycles might actually process more batches in the same amount of time.

The Critical Role of Atmosphere and Ventilation

The environment inside the furnace is just as important as the temperature. Failing to control it can contaminate samples or ruin processes.

Standard Air vs. Controlled Atmosphere

A standard muffle furnace operates in ambient air. This is sufficient for many applications like general ashing or simple heat-treating.

However, if your process is sensitive to oxygen (e.g., to prevent oxidation), you will need a furnace with controlled atmosphere capabilities. These models include gas-tight seals and ports for introducing inert gases like nitrogen or argon to displace the air.

Exhaust and Ventilation Systems

All muffle furnaces must be properly ventilated. Processes like ashing, binder burnout, or chemical conversions release fumes and combustion byproducts that must be safely removed.

An effective exhaust port or vent prevents these gases from contaminating the chamber or creating a hazardous work environment. Ensure your facility can accommodate the necessary ventilation for the model you choose.

Understanding the Trade-offs and Long-Term Costs

A furnace's sticker price is only one part of its total cost. Durability, energy consumption, and safety are long-term considerations.

Heating Element and Insulation Durability

As mentioned, Kanthal and silicon carbide (SiC) are common heating element materials. Kanthal is a workhorse for lower temperatures, while SiC is required for high-heat applications but can have a shorter lifespan and higher replacement cost.

High-quality ceramic fiber insulation contributes to faster heat-up times and better energy efficiency. A cheaper furnace may have lower-grade insulation, leading to higher electricity bills over its lifetime.

Safety Features and Placement

Safety is non-negotiable. Look for features like over-temperature protection and a door safety switch that cuts power when the door is opened. The furnace itself must be placed on a stable, non-combustible surface and properly grounded.

Ensure the workspace is free of any flammable materials and that operators are trained not to open the door at very high temperatures (e.g., >600°C) to avoid thermal shock and potential injury.

Manufacturer Reputation and Support

Choosing a reputable manufacturer ensures you are purchasing a reliable piece of equipment with available support and replacement parts. Check reviews and ask for references to gauge the long-term reliability and service quality associated with the brand.

Making the Right Choice for Your Goal

Ultimately, the best furnace is the one that directly serves your primary objective.

- If your primary focus is general-purpose ashing or heat-treating: A standard air furnace with a reliable digital controller and Kanthal elements is your most cost-effective choice.

- If your primary focus is high-temperature materials science (ceramics, alloys): Prioritize a furnace with SiC elements for high-temperature capability and excellent temperature uniformity.

- If your primary focus is sensitive analytical chemistry or processing reactive metals: A furnace with controlled atmosphere capabilities is essential to prevent oxidation and ensure process purity.

- If your primary focus is high-throughput production: Focus on robust construction, rapid heating/cooling rates, and the right chamber size to optimize batch cycles.

By systematically aligning these technical considerations with your specific application, you can confidently select a furnace that will serve as a reliable tool, not a source of error.

Summary Table:

| Key Consideration | Description |

|---|---|

| Maximum Temperature | Determines heating element type (e.g., Kanthal for ≤1200°C, SiC for higher temps) and cost. |

| Temperature Uniformity | Critical for consistent results; look for digital PID controllers. |

| Chamber Size | Balance sample capacity with energy efficiency; avoid oversizing. |

| Atmosphere Control | Needed for oxygen-sensitive processes; includes gas-tight seals for inert gases. |

| Heating/Cooling Rates | Programmable rates prevent thermal shock and optimize throughput. |

| Safety Features | Include over-temperature protection and door safety switches for operator safety. |

| Long-Term Costs | Consider durability, energy efficiency, and manufacturer support for total cost of ownership. |

Ready to find the perfect muffle furnace for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your laboratory's efficiency and reliability with a customized solution!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment