At its core, a muffle furnace is a laboratory-grade oven that provides a compact, enclosed environment for reaching extremely high and precisely controlled temperatures, often up to 1200°C (2200°F). It is used to transform materials through processes like ashing, heat treating, and sintering to analyze their composition, test their durability, or alter their physical properties.

The true value of a muffle furnace is not just its ability to get hot, but its capacity to perform controlled thermal decomposition and transformation. It allows you to strip a material down to its fundamental inorganic components or to fundamentally change its structure with precision.

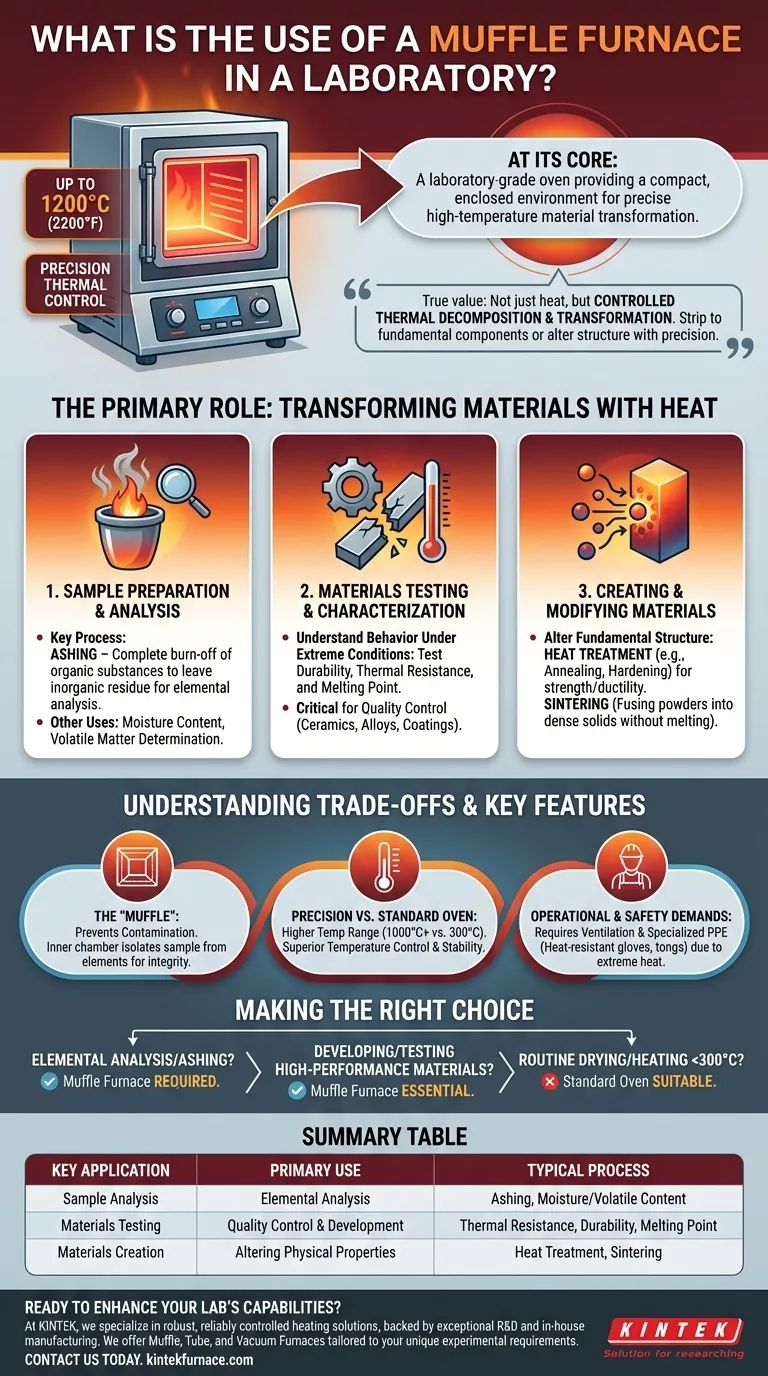

The Primary Role: Transforming Materials with Heat

A muffle furnace goes far beyond simple drying. Its purpose is to subject samples to thermal stress in a way that reveals or alters their basic characteristics.

Sample Preparation and Analysis

The most common laboratory use is preparing a sample for further chemical analysis. The high heat initiates specific chemical changes.

Ashing is the cornerstone of this process. It involves heating a sample to a temperature high enough to completely burn off all organic substances, leaving behind only the non-combustible inorganic residue, or ash. This ash can then be analyzed for its elemental composition.

Other analytical uses include determining a sample's moisture content or the amount of volatile matter that is released at high temperatures.

Materials Testing and Characterization

Engineers and material scientists use muffle furnaces to understand how a material behaves under extreme conditions.

By exposing a material to a specific temperature for a set duration, they can test its durability, thermal resistance, and melting point. This is critical for quality control and developing new materials like ceramics, alloys, and high-performance coatings.

Creating and Modifying Materials

A muffle furnace is also a tool for creation. Processes like heat treatment and sintering use temperature to fundamentally change a material's internal structure.

Heat treatment, such as annealing or hardening metals, alters properties like strength and ductility. Sintering is a process used for ceramics and some metals where fine powders are heated until their particles fuse together, forming a solid, dense object without melting.

Understanding the Trade-offs and Key Features

While powerful, a muffle furnace is a specialized instrument. Understanding its design and limitations is key to using it effectively.

The "Muffle": Preventing Contamination

The name comes from the furnace's design. The "muffle" is the inner chamber that isolates the sample from the heating elements. This is critical because it prevents contamination from the byproducts of combustion (in fuel-fired furnaces) or from the elements themselves, ensuring the sample's integrity.

Precision vs. A Standard Oven

A muffle furnace is not interchangeable with a standard laboratory oven. The key differentiators are its temperature range (often 1000°C+ vs. 300°C for a typical oven) and its temperature control system, which allows for highly precise and stable heating profiles.

Operational and Safety Demands

The extreme temperatures of a muffle furnace introduce significant operational requirements. Proper ventilation is mandatory to handle fumes, and operators must use specialized personal protective equipment (PPE), such as heat-resistant gloves and tongs, to prevent severe burns.

Making the Right Choice for Your Goal

Deciding whether you need a muffle furnace depends entirely on the transformation your material must undergo.

- If your primary focus is elemental analysis or determining inorganic content: You need a muffle furnace for precise ashing procedures.

- If your primary focus is developing or testing high-performance materials: A muffle furnace is essential for heat treatment, sintering, and thermal stress testing.

- If your primary focus is routine sample drying or heating below 300°C: A standard laboratory oven is a more suitable and cost-effective tool.

Ultimately, the muffle furnace is the indispensable tool for any laboratory process that requires subjecting materials to precisely controlled, extreme heat.

Summary Table:

| Key Application | Primary Use | Typical Process |

|---|---|---|

| Sample Analysis | Elemental Analysis | Ashing, Moisture/Volatile Content Determination |

| Materials Testing | Quality Control & Development | Thermal Resistance, Durability, Melting Point Testing |

| Materials Creation | Altering Physical Properties | Heat Treatment (Annealing), Sintering |

Ready to enhance your lab's capabilities with a high-performance furnace?

At KINTEK, we understand that precise thermal processing is critical for accurate results in research and quality control. Our expertise in advanced high-temperature furnace solutions, including Muffle, Tube, and Vacuum Furnaces, is backed by exceptional R&D and in-house manufacturing.

We specialize in providing robust, reliable, and precisely controlled heating for applications like ashing, heat treatment, and sintering. Our strong deep customization capability ensures your furnace is tailored to meet your unique experimental requirements perfectly.

Contact us today to discuss how we can provide the right high-temperature solution for your laboratory.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis