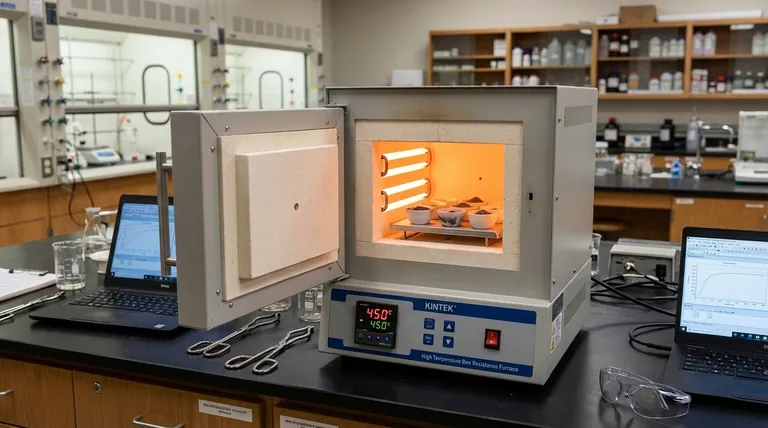

The high-temperature box resistance furnace acts as the definitive reaction environment for synthesizing silicon-doped ruthenium dioxide catalysts. It provides a precise, static thermal field—specifically at 450°C in an air atmosphere—which is required to drive the calcination and oxidation of precursors. This thermal treatment is the specific mechanism that transforms raw materials into a chemically active, doped crystal structure.

Core Takeaway: The furnace's primary function is to facilitate the complete decomposition of resin templates through stable heating. This process forces silicon and ruthenium atoms into a rutile phase crystal lattice, resulting in a robust interstitial doping structure essential for catalytic stability.

The Physics of Synthesis

Precise Thermal Control

The synthesis of this specific catalyst requires a sustained temperature of 450°C.

The box resistance furnace maintains a uniform temperature field throughout the chamber. This uniformity is critical to prevent thermal gradients that could lead to uneven doping or incomplete reaction of the precursors.

Oxidative Atmosphere

Unlike synthesis methods that require reducing environments, this process relies on an air atmosphere.

The box furnace design naturally accommodates calcination in air. This oxidative environment is necessary to convert the precursors into their oxide forms (Ruthenium Dioxide) rather than reducing them to metallic states.

Structural Transformation Mechanisms

Template Decomposition

The synthesis utilizes a resin template to guide the formation of the catalyst particles.

The heat from the furnace ensures the complete carbonization and decomposition of this resin. By thoroughly removing the organic template components, the furnace prevents impurities from interfering with the final active sites.

Lattice Engineering

The ultimate goal of the thermal treatment is atomic-level structural engineering.

As the resin decomposes and the temperature holds at 450°C, ruthenium and silicon atoms are energetically driven into a specific arrangement.

Interstitial Doping

The thermal process facilitates the entry of these atoms into the rutile phase crystal lattice.

This results in a stable interstitial doping structure. The furnace's ability to hold the temperature precisely ensures that the doping is consistent, maximizing the structural integrity and performance of the final catalyst particle.

Understanding the Trade-offs

Box Furnace vs. Tube Furnace

It is vital to select the correct furnace based on the chemical reaction required.

A box resistance furnace is ideal for the oxidation and calcination processes described here (static air, 450°C). It excels at batch processing in oxidative environments.

In contrast, a tube furnace is typically required when a controlled reducing atmosphere (such as H2/Ar) is needed. As noted in comparative processes, tube furnaces are used to reduce metal oxides into alloys, whereas the box furnace is used here to create the oxide structure.

Making the Right Choice for Your Goal

To ensure synthesis success, align your equipment choice with your chemical pathway:

- If your primary focus is Ruthenium Dioxide synthesis: Use a box resistance furnace at 450°C to ensure proper oxidation and lattice formation in an air atmosphere.

- If your primary focus is Metallic Alloy reduction: Switch to a tube furnace to maintain the necessary hydrogen/argon reducing environment.

The quality of your final catalyst is directly dependent on the stability of the thermal field during the lattice formation phase.

Summary Table:

| Feature | Specification/Role |

|---|---|

| Optimal Temperature | 450°C (Stable Static Thermal Field) |

| Atmosphere | Ambient Air (Oxidative Environment) |

| Key Mechanism | Resin Template Decomposition & Lattice Engineering |

| Crystalline Phase | Rutile Phase Interstitial Doping |

| Equipment Choice | Box Resistance Furnace (for Oxidation vs. Tube for Reduction) |

Elevate Your Catalyst Synthesis with KINTEK Precision

Precision at 450°C is the difference between an inactive precursor and a high-performance rutile catalyst. KINTEK provides the specialized Muffle and Box Resistance Furnaces required for stable oxidation and complex lattice engineering.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique laboratory requirements. Whether you are performing air-atmosphere calcination or H2/Ar reduction, our equipment ensures uniform heating and repeatable results for your most sensitive materials research.

Ready to optimize your thermal processing? Contact our technical experts today to find the perfect furnace solution.

References

- Xinyu Ping, Zidong Wei. Locking the lattice oxygen in RuO2 to stabilize highly active Ru sites in acidic water oxidation. DOI: 10.1038/s41467-024-46815-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How are muffle furnaces used in forensic investigations? Uncover Hidden Evidence with Precision Ashing

- Why is a high-temperature Muffle Furnace required for SiNW manufacturing? Optimize Solid-State Dewetting Processes

- What are the primary uses of muffle furnaces in the pharmaceutical industry? Ensure Drug Purity and Stability

- What is the primary function of a muffle furnace in PI microfibers? Enhance Polyimide Thermal Imidization

- What role does a Muffle Furnace play in processing steel and soil samples for cobalt extraction? Essential Lab Guide

- What is the function of a high-temperature muffle furnace? Master Polycrystalline MgSiO3 and Mg2SiO4 Synthesis

- What is the primary function of an industrial box furnace? Master 60Si2CrV Spring Steel Heat Treatment

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites