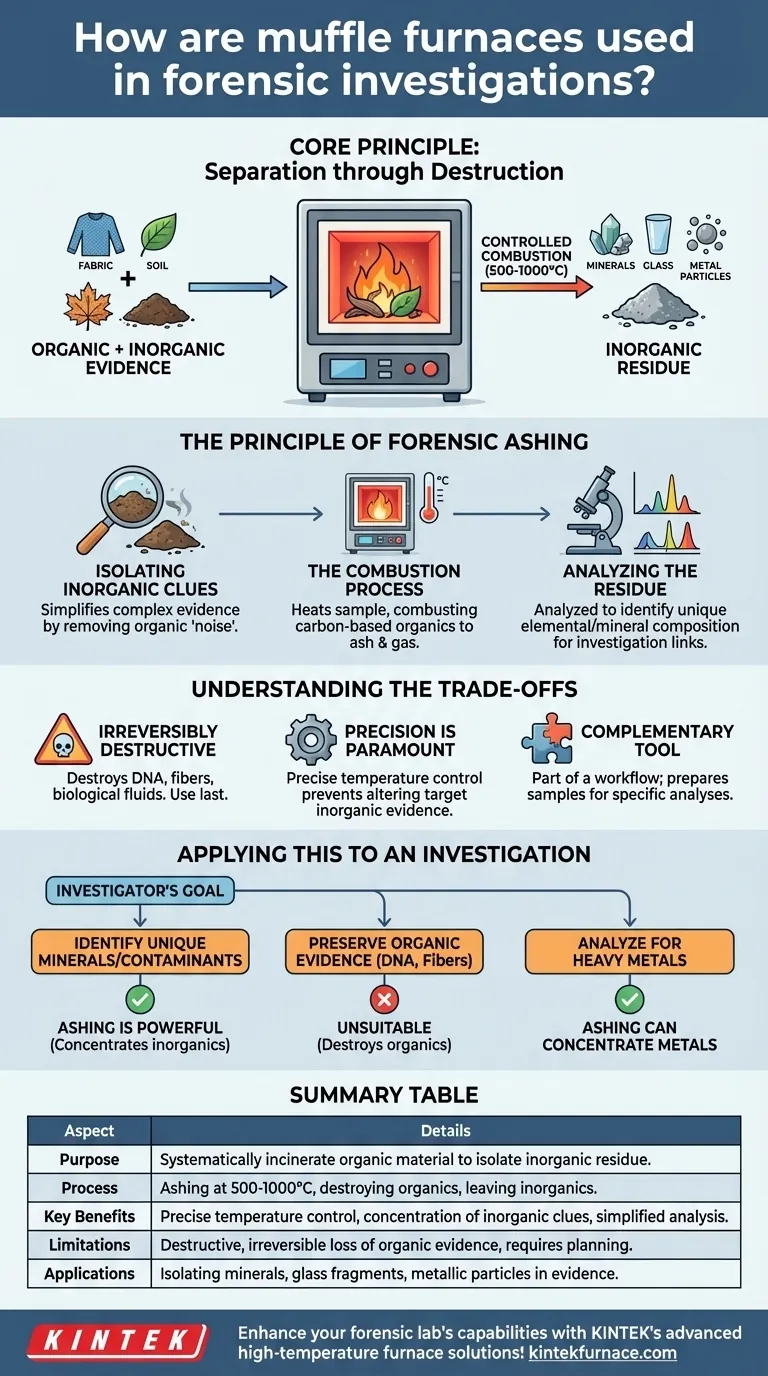

In forensic investigations, muffle furnaces serve a singular, powerful purpose: they are used to systematically incinerate organic material from a piece of evidence. This controlled combustion process burns away substances like fabric, tissue, or soil organics, leaving behind only the non-combustible, inorganic residue for analysis.

The core principle is separation through destruction. By using precisely controlled high temperatures to eliminate organic matter, investigators can isolate and concentrate inorganic materials—such as unique minerals, glass fragments, or metallic particles—that can provide crucial links in an investigation.

The Principle of Forensic Ashing

The use of a muffle furnace in forensics is a process known as ashing. It is designed to simplify a complex evidence sample down to its essential inorganic components.

Isolating Inorganic Clues

Most physical evidence is a mixture. A soil sample on a suspect's shoe contains both organic matter (decomposing plants) and inorganic matter (sand, clay, minerals). A piece of burnt cloth from an arson scene may contain both the original fabric and a foreign chemical accelerant. Ashing removes the organic "noise" to reveal the inorganic "signal."

The Combustion Process

Inside the furnace, a sample is heated to temperatures that can exceed 500-1000°C. This extreme heat causes the carbon-based organic compounds to combust and turn into ash and gas, which are then vented. What remains is a small amount of residue that is purely inorganic.

Analyzing the Residue

This remaining residue is where the evidentiary value lies. It can be analyzed using techniques like microscopy or spectroscopy to identify its elemental and mineral composition. The goal is to find materials that are unique or out of place, potentially linking a suspect to a victim or a crime scene.

Understanding the Trade-offs

While powerful, ashing is not a universal solution. Its application requires careful consideration of the evidence and the investigative goals.

It Is a Destructive Technique

The most significant trade-off is that the process is irreversibly destructive. Any organic information, such as DNA, fibers, or biological fluids, is completely destroyed. Therefore, a sample is only ashed after all other potential analyses are complete, or if a sub-sample is specifically designated for this purpose.

Precision Is Paramount

The references highlight that muffle furnaces offer precise temperature control, which is critical. Different inorganic compounds have different melting or vaporization points. If the temperature is too high, the very evidence an investigator is trying to isolate could be altered or destroyed, rendering the analysis invalid.

It Is a Complementary Tool

Ashing is rarely the sole method of analysis. It is one step in a larger analytical workflow. Evidence is typically examined visually and microscopically first. Ashing is then used to prepare the sample for more specific inorganic analyses, acting as a bridge between the raw evidence and the final chemical data.

Applying This to an Investigation

Deciding to use a muffle furnace depends entirely on what information an investigator needs to find.

- If your primary focus is identifying unique minerals or industrial contaminants: Ashing is a powerful method for concentrating these inorganic materials from a complex organic matrix like soil or dust.

- If your primary focus is preserving organic evidence like DNA or fibers: This technique is entirely unsuitable, as its sole purpose is to destroy the organic components of the sample.

- If your primary focus is analyzing for the presence of heavy metals: Ashing can concentrate metallic particles from a sample, making them easier to detect and quantify in subsequent tests.

Ultimately, the use of a muffle furnace in forensics is a calculated decision to destroy one part of the evidence to reveal the secrets hidden within another.

Summary Table:

| Aspect | Details |

|---|---|

| Purpose | Systematically incinerate organic material to isolate inorganic residue for analysis. |

| Process | Ashing at 500-1000°C, destroying organics like fabric or tissue, leaving inorganics. |

| Key Benefits | Precise temperature control, concentration of inorganic clues, simplified evidence analysis. |

| Limitations | Destructive technique, irreversible loss of organic evidence, requires careful planning. |

| Applications | Isolating minerals, glass fragments, metallic particles in soil, dust, or arson evidence. |

Enhance your forensic lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored for precise forensic ashing. Our deep customization ensures your unique experimental needs are met, helping you isolate critical inorganic evidence efficiently. Contact us today to discuss how our furnaces can support your investigations!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production