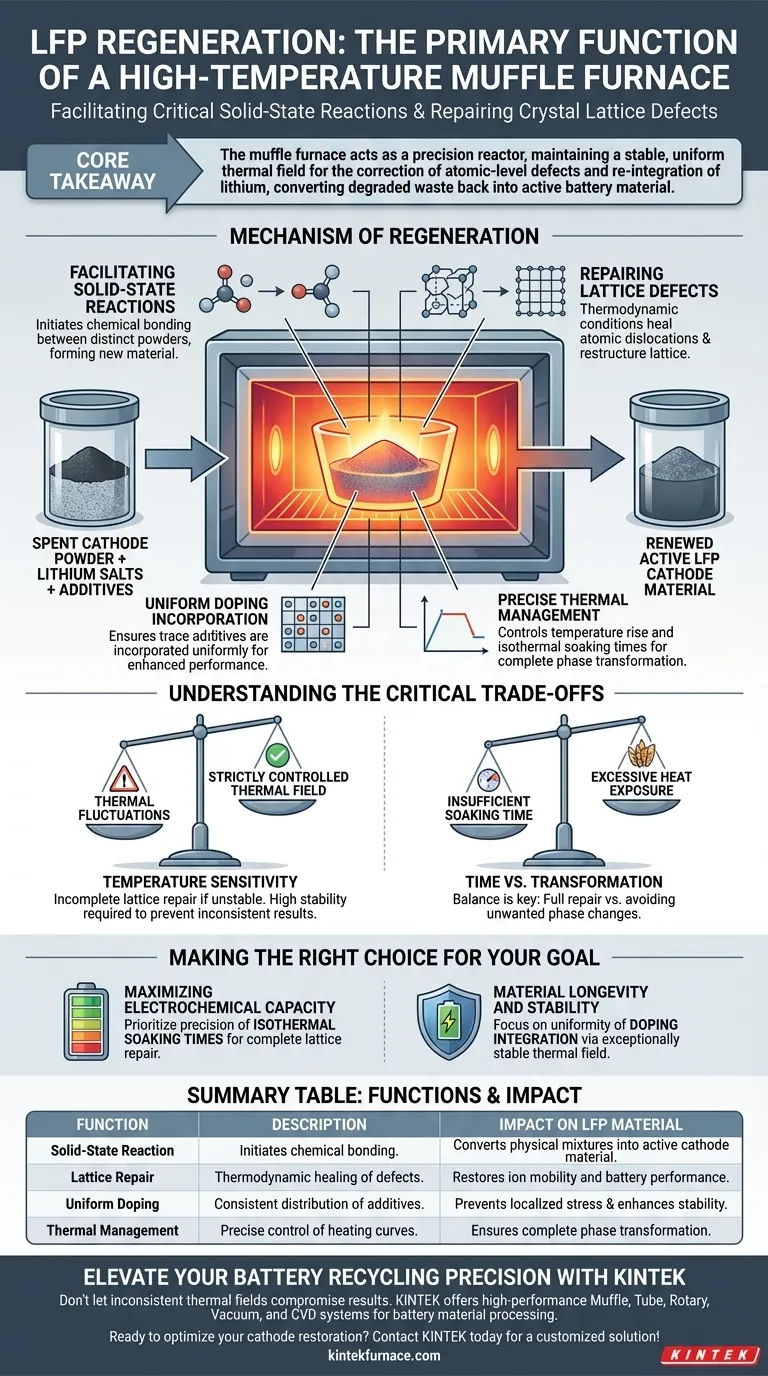

The primary function of a high-temperature muffle furnace in LFP regeneration is to facilitate critical solid-state reactions within a mixture of spent cathode powder, lithium salts, and additives. By strictly controlling the thermal environment—specifically temperature rise curves and isothermal soaking times—the furnace enables the repair of crystal lattice defects and restores the material's electrochemical activity.

Core Takeaway The muffle furnace acts as a precision reactor that drives the chemical restoration of spent LFP material. Its ability to maintain a stable, uniform thermal field is what allows for the correction of atomic-level defects and the re-integration of lithium, converting degraded waste back into active battery material.

The Mechanism of Regeneration

Facilitating Solid-State Reactions

The regeneration process relies on mixing spent LFP precursors with fresh lithium salts and doping additives.

The muffle furnace provides the energy required to initiate and sustain solid-state reactions between these distinct powders.

Without this high-temperature environment, the components would remain a physical mixture rather than chemically bonding to form renewed cathode material.

Repairing Lattice Defects

Over the life of a battery, the crystal structure (lattice) of the cathode material degrades and develops defects.

The furnace's controlled heat provides the thermodynamic conditions necessary to heal these atomic dislocations.

This restructuring is essential for ensuring the ions can move freely within the material again, which is the basis of battery performance.

Uniform Doping Incorporation

To enhance performance, doping elements (trace additives) are often introduced during regeneration.

The furnace ensures these elements are incorporated uniformly throughout the material structure.

Uniform distribution is critical; uneven doping can lead to localized stress and premature failure in the regenerated battery.

Precise Thermal Management

The success of the regeneration is dictated by the heating profile, not just the maximum temperature.

The muffle furnace manages temperature rise curves and isothermal soaking times (holding the material at a specific heat for a specific duration).

This precision ensures that the phase transformation is complete without overheating or degrading the material components.

Understanding the Critical Trade-offs

Temperature Sensitivity

While muffle furnaces offer excellent isolation, the process is highly sensitive to thermal fluctuations.

If the furnace cannot maintain a strictly controlled thermal field, the lattice repair will be incomplete.

As noted in broader research applications, materials sensitive to temperature changes require a furnace with high stability to prevent inconsistent results.

Time vs. Transformation

There is a delicate balance between the soaking time and reaction completeness.

Insufficient soaking time prevents the full repair of lattice defects, resulting in lower electrochemical activity.

Conversely, excessive heat exposure can lead to grain growth or unwanted phase changes, counteracting the benefits of regeneration.

Making the Right Choice for Your Goal

To maximize the effectiveness of your LFP regeneration process, align your thermal strategy with your specific objectives:

- If your primary focus is maximizing electrochemical capacity: Prioritize the precision of your isothermal soaking times to ensure complete lattice repair and defect elimination.

- If your primary focus is material longevity and stability: Focus on the uniformity of doping integration by ensuring your furnace provides an exceptionally stable thermal field during the reaction phase.

The muffle furnace is not merely a heating element; it is the environment where the structural integrity and value of the cathode material are reclaimed.

Summary Table:

| Function | Description | Impact on LFP Material |

|---|---|---|

| Solid-State Reaction | Initiates chemical bonding between spent powder and lithium salts. | Converts physical mixtures into active cathode material. |

| Lattice Repair | Thermodynamic healing of atomic dislocations and defects. | Restores ion mobility and battery performance. |

| Uniform Doping | Ensures consistent distribution of trace additives throughout the structure. | Prevents localized stress and enhances material stability. |

| Thermal Management | Precise control of heating curves and isothermal soaking times. | Ensures complete phase transformation without degradation. |

Elevate Your Battery Recycling Precision with KINTEK

Don't let inconsistent thermal fields compromise your LFP regeneration results. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the rigorous demands of battery material processing.

Whether you need to maximize electrochemical capacity through precise isothermal soaking or ensure long-term stability via uniform doping, our lab high-temperature furnaces are fully customizable to meet your unique research and production needs.

Ready to optimize your cathode restoration? Contact KINTEK today for a customized solution!

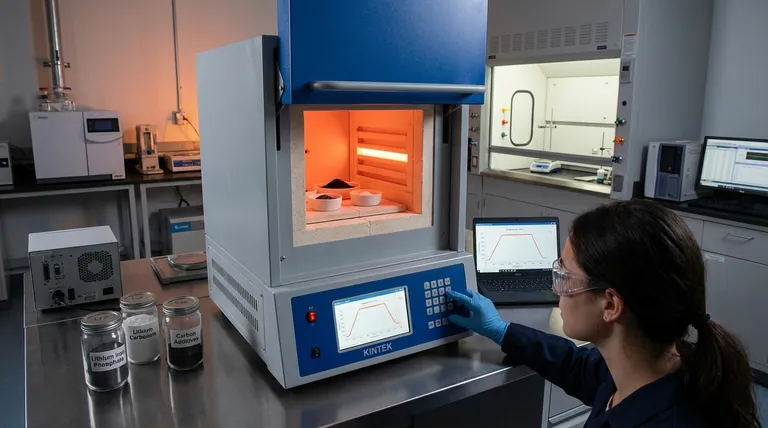

Visual Guide

References

- Cheng-Yan Huang, Hongxia Han. Sustainable Regeneration of Spent LiFePO <sub>4</sub> Cathode with Al‐Doping. DOI: 10.1002/ente.202500113

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How are muffle furnaces utilized in dental labs? Essential for Precision Dental Restorations

- What applications do muffle furnaces have in ceramics? Unlock Precision Firing for Superior Results

- What are the benefits of muffle furnaces compared to tube furnaces? Choose the Right Furnace for Your Lab

- How do a laboratory high-temperature box furnace and water quenching work together? Optimize High-Manganese Steel

- What temperature ranges can muffle furnaces achieve? Find the Perfect Heat for Your Lab Needs

- Why are muffle furnaces critical in research and development? Unlock Precise, Contaminant-Free High-Temp Processing

- How does the muffle design contribute to furnace performance? Enhance Purity, Uniformity, and Efficiency

- How does a muffle furnace compare to other high-temperature furnaces in terms of cost? Discover Affordable Heat Treatment Solutions