In a dental laboratory, a muffle furnace is the essential high-temperature oven used to transform raw materials into finished dental restorations. It is the primary tool for processes like sintering zirconia, firing porcelain onto crowns and bridges, and burning out wax patterns for casting, ensuring the final product has the required strength, fit, and aesthetic appearance.

The core purpose of a muffle furnace in dentistry is not just to heat materials, but to provide an exceptionally precise and clean environment. This control allows technicians to trigger specific chemical and physical transformations in materials like ceramic and zirconia, turning them from a fragile state into a durable, tooth-like restoration.

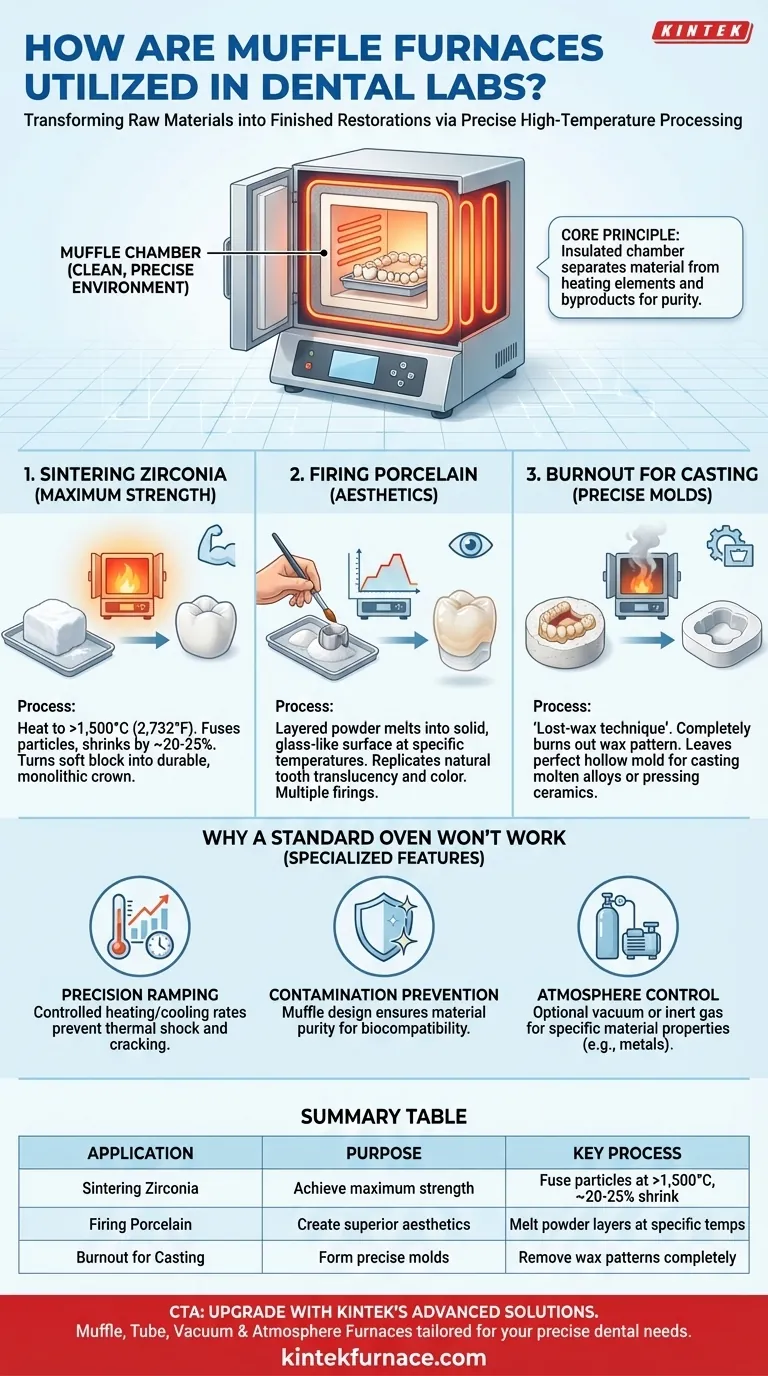

The Core Principle: From Powder to Prosthesis

A muffle furnace is fundamentally a furnace with an insulated inner chamber (the "muffle") that separates the material being heated from the heating elements and any combustion byproducts. This design is critical for dental applications where material purity is paramount.

Sintering for Maximum Strength

The most common modern use is for sintering zirconia. Zirconia crowns are milled from a soft, chalk-like block.

Placing this pre-shaped crown in the furnace and heating it to temperatures often exceeding 1,500°C (2,732°F) initiates sintering. This process fuses the material's particles together, shrinking the crown by about 20-25% and transforming it into one of the strongest and most durable materials in dentistry.

Firing Porcelain for Aesthetics

For Porcelain-Fused-to-Metal (PFM) or all-ceramic crowns, technicians build up layers of fine porcelain powder mixed with a liquid.

Each layer is fired in the muffle furnace at specific temperatures. This firing process melts the powder particles into a solid, glass-like layer that mimics the translucency and color of a natural tooth. Multiple firings are needed to build up the final shape and glaze the surface.

Casting and Pressing via Burnout

Muffle furnaces are also used for the "lost-wax technique." A wax pattern of the desired restoration is encased in a plaster-like material called investment.

The furnace is used to burn out the wax completely, leaving a perfectly shaped hollow mold inside the investment. This mold is then used for casting molten metal alloys or pressing high-strength ceramics to create the final framework or restoration.

Why a Standard Oven Won't Work

Using a specialized muffle furnace is non-negotiable in a dental lab due to the precise demands of dental materials. The differences go far beyond simply reaching a high temperature.

Critical Need for Precision Ramping

Dental materials are highly sensitive to thermal shock. They cannot be heated or cooled too quickly without cracking or developing internal stresses that lead to failure.

Muffle furnaces are programmable, allowing technicians to control the rate of temperature increase (ramping) and implement holds at specific temperatures. This ensures the material transforms evenly and predictably.

Preventing Material Contamination

The muffle design is key. It creates a clean chamber where the restoration is not exposed to any contaminants from the heating elements.

This is vital for biocompatible materials used in the human body. Any contamination could compromise the material's strength, color, and safety.

Atmosphere Control

Some advanced processes, like sintering certain metals, require a specific atmosphere (e.g., a vacuum or an inert gas like argon). Muffle furnaces can be designed with these capabilities to prevent oxidation and ensure the desired material properties are achieved.

Key Applications and Their Purpose

Your understanding of the furnace's role depends on the final product you are trying to create.

- If your primary focus is ultimate strength and durability: The key process is sintering zirconia, which turns a soft pre-milled shape into a monolithic, high-strength final restoration.

- If your primary focus is superior aesthetics: The key process is the meticulous layering and firing of porcelain to replicate the natural translucency, color, and surface texture of a tooth.

- If your primary focus is creating metal-based substructures: The key process is the burnout of wax patterns to create a precise mold for casting molten alloys.

Ultimately, the muffle furnace is the engine of material science within the dental lab, enabling the creation of durable, functional, and lifelike restorations.

Summary Table:

| Application | Purpose | Key Process |

|---|---|---|

| Sintering Zirconia | Achieve maximum strength and durability | Heating to >1,500°C to fuse particles, shrinking by 20-25% |

| Firing Porcelain | Create superior aesthetics and natural tooth appearance | Melting layers of porcelain powder at specific temperatures |

| Burnout for Casting | Form precise molds for metal or ceramic frameworks | Removing wax patterns to create hollow molds in investment material |

Upgrade your dental lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored for precise sintering, firing, and burnout processes. Our deep customization capabilities ensure your unique experimental needs are met, enhancing efficiency and restoration quality. Contact us today to discuss how our furnaces can transform your dental restorations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations