In the field of ceramics, muffle furnaces are fundamentally used for firing—the critical high-temperature process that transforms pliable clay into a hard, durable ceramic object. Their design provides the precise temperature control and clean heating environment necessary for creating everything from pottery and tiles to advanced technical ceramics and enamel coatings.

A muffle furnace's primary advantage for ceramics is its design, which physically separates the object being heated from the furnace's heating elements. This "muffle" prevents contamination from fuel or electrical byproducts, ensuring a clean atmosphere that is crucial for the final appearance and integrity of the ceramic piece and its glazes.

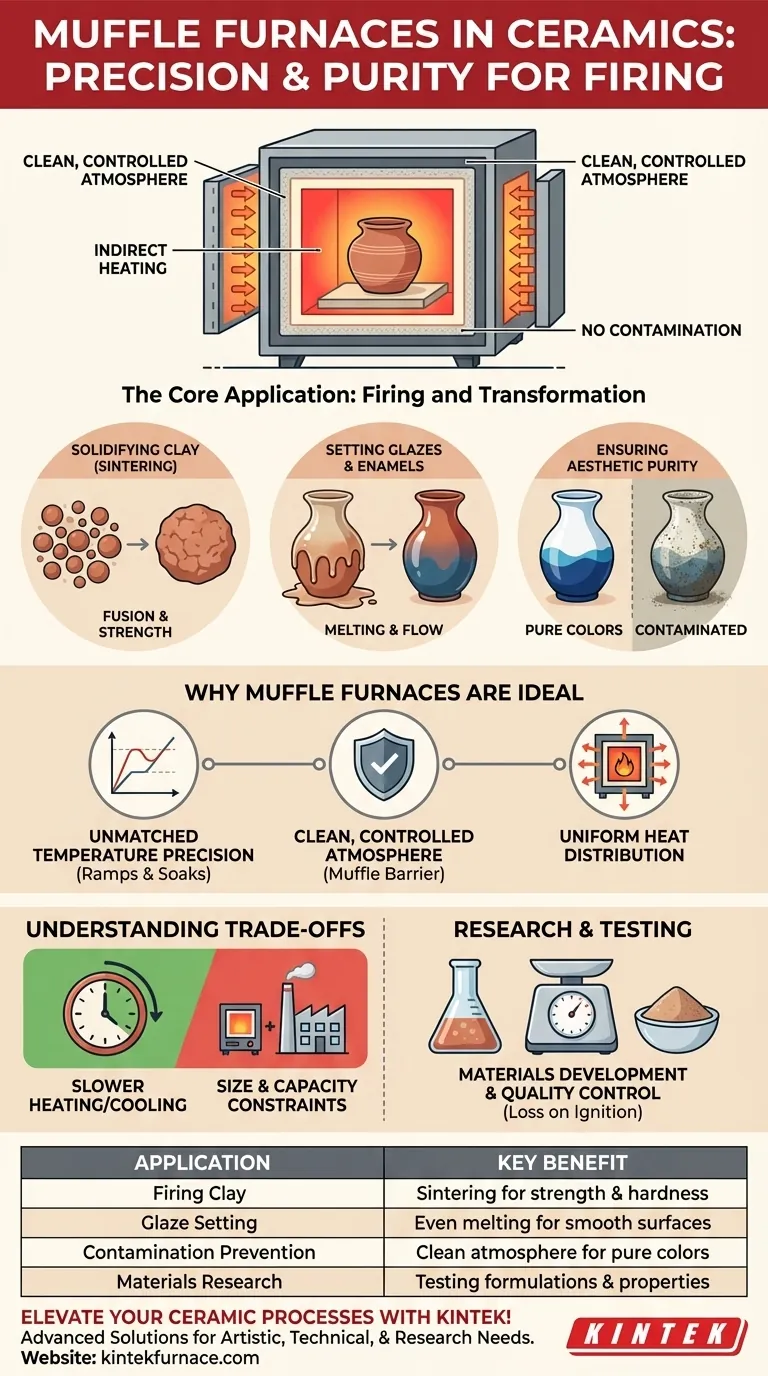

The Core Application: Firing and Transformation

The most essential use of a muffle furnace in ceramics is to thermally process clay and glazes. This firing process is not a single action but a carefully controlled sequence of events.

Solidifying the Clay Body

At high temperatures, the particles within a clay body undergo a process called sintering. The particles fuse together, densifying the material, removing porosity, and giving the ceramic piece its final strength and hardness.

Setting Glazes and Enamels

Glazes and enamels are essentially a form of glass. The furnace melts these coatings, allowing them to flow evenly over the ceramic surface and fuse to it, creating a smooth, impervious, and often decorative layer.

Ensuring Aesthetic Purity

The clean environment inside a muffle furnace is paramount. It prevents soot, ash, or other contaminants from the heat source from embedding in or discoloring the clay body and glazes, which is critical for achieving pure whites and vibrant colors.

Why Muffle Furnaces Are Ideal for Ceramics

The specific construction of a muffle furnace offers several advantages that make it a standard tool in both artistic studios and industrial ceramic production.

Unmatched Temperature Precision

Modern muffle furnaces offer exceptional control over the firing schedule. This allows users to program specific heating rates (ramps), holding times (soaks), and cooling profiles, which are essential for complex chemical reactions in glazes and for preventing thermal shock in the ceramic body.

A Clean, Controlled Atmosphere

The muffle is a ceramic shell that shields the workload. This indirect heating method is the furnace's defining feature. It guarantees that the atmosphere is composed only of air and any gases released by the ceramic piece itself, not byproducts of combustion.

This design also makes it suitable for creating a controlled atmosphere by introducing specific gases if advanced chemical changes, like in reduction firing, are desired.

Uniform Heat Distribution

A well-designed muffle furnace provides excellent heat uniformity throughout the chamber. This even heating ensures the entire ceramic piece matures at the same rate, minimizing the risk of stress, cracking, or warping.

Understanding the Trade-offs

While highly effective, muffle furnaces are not without limitations. Understanding these trade-offs is key to using them properly.

Slower Heating and Cooling

The ceramic muffle that protects the workpiece also acts as a thermal barrier. This means muffle furnaces can have slower heating and cooling rates compared to direct-fired kilns, potentially leading to longer overall cycle times.

Size and Capacity Constraints

Muffle furnaces, particularly those used in laboratory or studio settings, are often smaller than the large-scale industrial kilns used for mass production. Their capacity can be a limiting factor for high-volume manufacturing.

Materials Research and Testing

Beyond finished products, muffle furnaces are used in ceramic research labs to test new material formulations. They are used to determine properties like loss on ignition (weight lost upon heating) or ash content of raw clays and additives, which is vital for quality control.

Making the Right Choice for Your Goal

Your specific objective in ceramics will determine how you leverage a muffle furnace.

- If your primary focus is artistic pottery or sculpture: The muffle furnace is your core tool for both bisque and glaze firing, ensuring clean colors and a strong final product.

- If your primary focus is developing new glazes or clay bodies: Use a muffle furnace for precise, repeatable test firings and to analyze raw materials.

- If your primary focus is producing technical or advanced ceramics: Rely on a muffle furnace for sintering powdered materials under tightly controlled atmospheric and temperature conditions.

Ultimately, the muffle furnace provides the control and purity required to consistently achieve desired outcomes in the demanding art and science of ceramics.

Summary Table:

| Application | Key Benefit |

|---|---|

| Firing Clay | Sintering for strength and hardness |

| Glaze Setting | Even melting and fusion for smooth surfaces |

| Contamination Prevention | Clean atmosphere for pure colors and integrity |

| Materials Research | Testing formulations and properties like loss on ignition |

Elevate your ceramic processes with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Muffle, Tube, and Rotary Furnaces, as well as Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs—whether for artistic pottery, technical ceramics, or material testing. Contact us today to discuss how our solutions can enhance your efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production