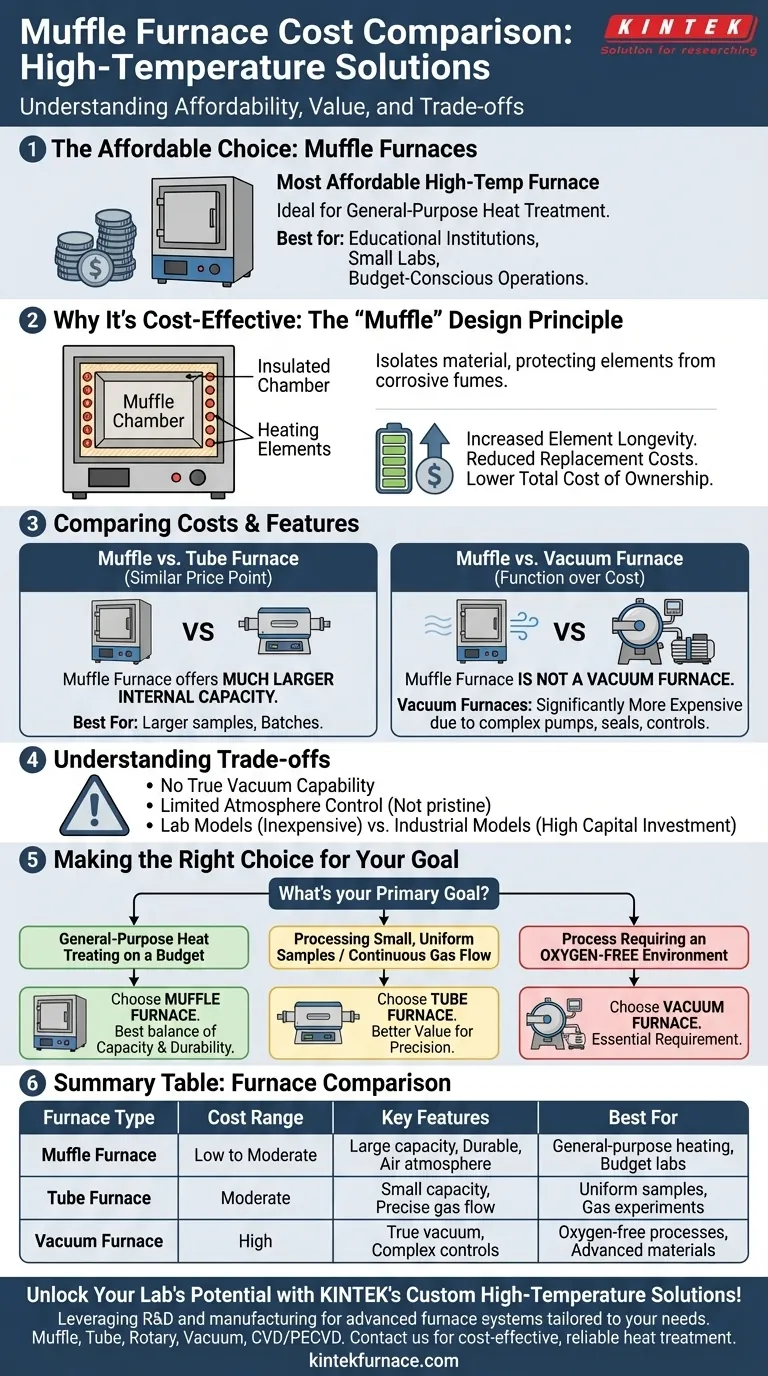

In terms of cost, a muffle furnace is generally one of the most affordable types of high-temperature furnaces available. Their straightforward design and wide range of applications make them a cost-effective choice for general-purpose heat treatment, especially for educational institutions, small-scale labs, and budget-conscious industrial operations.

A muffle furnace's value proposition is its balance of cost, capacity, and durability. You get a large, robust heating chamber for your investment, but this affordability comes with specific trade-offs, particularly the inability to create a true vacuum.

The Source of a Muffle Furnace's Value

The cost-effectiveness of a muffle furnace is not arbitrary; it stems directly from its core design and the specific problems it solves.

The "Muffle" Design Principle

A muffle furnace contains an insulated inner chamber—the "muffle"—that isolates the material being heated from the furnace's heating elements.

This separation prevents corrosive fumes or vapors released from the sample from directly contacting and damaging the elements.

Impact on Longevity and Cost

By protecting the heating elements, this design significantly increases their lifespan and reduces the frequency of costly replacements.

This inherent durability lowers the total cost of ownership over the furnace's life, making it a sound long-term investment for many applications.

How Muffle Furnaces Compare to Alternatives

Cost is only meaningful when compared to other options. The value of a muffle furnace becomes clear when placed side-by-side with other common furnace types.

Muffle Furnace vs. Tube Furnace

At a similar price point, a muffle furnace typically offers a much larger internal capacity than a tube furnace.

If your primary need is to heat larger samples or batches of material, the muffle furnace provides more volume for your money. Tube furnaces are more specialized for small, highly uniform samples or processes involving a continuous flow of gas.

Muffle Furnace vs. Vacuum Furnace

This comparison is less about cost and more about function. A muffle furnace is not a vacuum furnace.

Muffle furnaces are designed for heating in an air atmosphere or a modified one (by purging with inert gas). Vacuum furnaces are highly specialized, complex machines built to remove atmosphere entirely. This requires vacuum pumps, sophisticated seals, and controls, making them significantly more expensive.

Understanding the Trade-offs

The affordability of a muffle furnace comes with clear limitations. Understanding these is critical to avoid making a costly purchasing mistake.

The Lack of a True Vacuum

The most significant trade-off is the inability to create a high-vacuum environment.

If your process is sensitive to oxygen or requires the removal of all atmospheric gases (e.g., in certain types of brazing or sintering advanced materials), a muffle furnace is the wrong tool. Attempting to use it as a substitute will lead to failed processes.

Atmosphere Control Limitations

While you can purge a muffle furnace with an inert gas like nitrogen or argon to reduce oxygen, it does not provide the pristine, controlled environment of a sealed vacuum furnace.

The level of atmospheric purity required by your application is a key factor in determining if a muffle furnace is sufficient.

Lab vs. Industrial Models

The term "muffle furnace" covers a broad range of equipment. Small laboratory models operating up to 1200°C are relatively inexpensive.

In contrast, large industrial models built for high-throughput production or achieving extreme temperatures (up to 1800°C or higher) represent a much larger capital investment.

Making the Right Choice for Your Goal

Your application's specific requirements, not just the initial price tag, should dictate your choice of furnace.

- If your primary focus is general-purpose heat treating on a budget: A muffle furnace is likely your most cost-effective option, offering the best balance of capacity and durability.

- If your primary focus is processing small, uniform samples or continuous gas-flow experiments: A tube furnace may provide better value and precision for your specific task, despite its smaller volume.

- If your primary focus is any process requiring an oxygen-free environment: You must invest in a dedicated vacuum furnace, as a muffle furnace cannot meet this fundamental requirement.

Ultimately, choosing the right furnace is about aligning the tool's capabilities with your specific scientific or industrial goal.

Summary Table:

| Furnace Type | Cost Range | Key Features | Best For |

|---|---|---|---|

| Muffle Furnace | Low to Moderate | Large capacity, durable, air atmosphere | General-purpose heating, budget labs |

| Tube Furnace | Moderate | Small capacity, precise gas flow | Uniform samples, gas experiments |

| Vacuum Furnace | High | True vacuum, complex controls | Oxygen-free processes, advanced materials |

Unlock Your Lab's Potential with KINTEK's Custom High-Temperature Solutions!

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced furnace systems tailored to your needs. Our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet unique experimental requirements.

Whether you're in education, research, or industry, we help you achieve cost-effective, reliable heat treatment. Contact us today to discuss how our solutions can enhance your efficiency and results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- Why is a muffle furnace used to determine the ash content of biochar? Master Your Material Purity Analysis

- What is the primary role of a muffle furnace in the annealing process of AlCrTiVNbx alloys? Enhance Alloy Strength

- Why are precision stirring and drying equipment necessary for photocatalytic materials? Master Microstructure Control

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration