In short, a muffle furnace is a high-temperature workhorse used across research and industry for any process requiring precise thermal treatment in a contained environment. Its major applications include reducing samples to ash for chemical analysis, heat-treating metals to alter their properties, and testing the performance of advanced materials under extreme heat.

The versatility of a muffle furnace stems from one core principle: its "muffle," or inner chamber, isolates the material being heated from direct contact with the heating elements. This prevents contamination and ensures highly uniform temperature, making it an essential tool for processes that demand precision and purity.

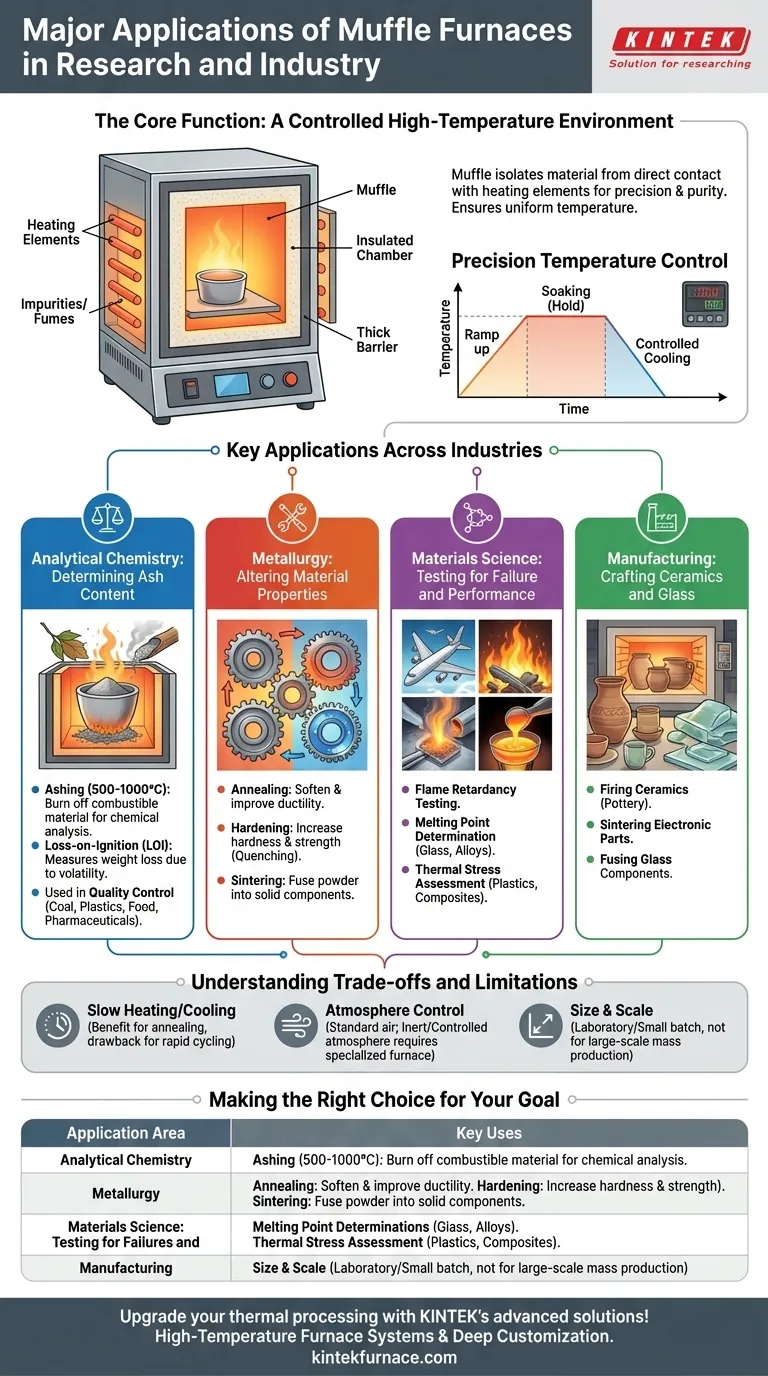

The Core Function: A Controlled High-Temperature Environment

A muffle furnace is more than just a simple oven. Its design is fundamental to its wide range of applications.

What is the "Muffle"?

The "muffle" is the furnace's insulated inner chamber, which acts as a barrier between the sample and the electric heating elements.

This separation is critical. It shields the sample from impurities given off by the heating elements and protects the elements from any fumes or splashes from the sample.

The result is a pristine, uniformly heated environment, which is non-negotiable for sensitive scientific analysis and advanced material processing.

Precision Temperature Control

Modern muffle furnaces offer exceptional temperature control, often with programmable cycles.

This allows users to execute complex thermal profiles, such as slowly ramping up to a specific temperature, holding it for a set duration (soaking), and then controlling the cooling rate. This repeatability is vital for both research and quality control.

Key Applications Across Industries

The combination of a clean, controlled, high-temperature environment makes the muffle furnace indispensable in numerous fields.

Analytical Chemistry: Determining Ash Content

One of the most common uses is ashing. A sample, often organic or polymeric, is heated to a high temperature (typically 500-1000°C) to completely burn off all combustible material.

The remaining inorganic, non-combustible residue is the ash. By weighing the sample before and after this process, analysts can accurately determine the ash content percentage.

This is a standard quality control test for materials like coal, plastics, food, and pharmaceuticals. A related test is Loss-on-Ignition (LOI), which measures weight loss due to high-temperature volatility.

Metallurgy: Altering Material Properties

The metallurgical industry relies heavily on muffle furnaces for various heat treatments that modify the physical and mechanical properties of metals.

Key processes include:

- Annealing: Heating and slowly cooling a metal to soften it, improve ductility, and relieve internal stresses.

- Hardening: Heating a metal to a critical temperature and then rapidly cooling it (quenching) to increase its hardness and strength.

- Sintering: Heating powdered materials below their melting point to fuse the particles together, forming a solid, high-strength component. This is used in powder metallurgy and for creating certain ceramic parts.

Materials Science: Testing for Failure and Performance

Engineers and researchers use muffle furnaces to understand how materials behave under thermal stress.

This includes testing the flame retardancy of aerospace components, determining the melting or fusion point of glass and alloys, and assessing the strength of plastics or composites after high-temperature exposure.

Manufacturing: Crafting Ceramics and Glass

Muffle furnaces are central to the creation of ceramics, enamels, and glass.

Processes like firing clay to create pottery, sintering advanced ceramic parts for electronics, and fusing glass components all take place within the controlled environment of a furnace.

Understanding the Trade-offs and Limitations

While highly versatile, a muffle furnace is not the solution for every thermal problem. Understanding its limitations is crucial for proper application.

Rate of Heating and Cooling

Due to their heavy insulation, most muffle furnaces heat and cool relatively slowly. This can be a benefit for processes like annealing but a drawback when rapid cycling is needed.

Atmosphere Control

A standard muffle furnace operates with a normal air atmosphere. If a process requires an inert or controlled atmosphere (e.g., using nitrogen or argon to prevent oxidation), a specialized and more expensive furnace is required.

Size and Scale

Muffle furnaces are typically designed for laboratory-scale or small batch production. While larger industrial versions exist, they are generally not used for the kind of continuous mass production seen in large-scale steel or cement manufacturing.

Making the Right Choice for Your Goal

Selecting the correct thermal process depends entirely on your objective.

- If your primary focus is quantitative analysis: Your goal is precision, so a standard muffle furnace with accurate temperature control is perfect for ashing or LOI testing.

- If your primary focus is metallurgical heat treatment: You need a furnace capable of reaching specific target temperatures and may need to consider if atmosphere control is necessary to prevent oxidation.

- If your primary focus is materials R&D: Versatility is key, so a furnace with programmable temperature profiles and a wide operating range will allow for the greatest experimental flexibility.

By understanding its core function as a source of clean, controlled heat, you can apply the muffle furnace to solve an incredible range of technical challenges.

Summary Table:

| Application Area | Key Uses |

|---|---|

| Analytical Chemistry | Ashing, Loss-on-Ignition (LOI) for quality control in coal, plastics, food, and pharmaceuticals |

| Metallurgy | Annealing, hardening, sintering to alter metal properties |

| Materials Science | Flame retardancy testing, melting point determination, high-temperature exposure assessments |

| Manufacturing | Firing ceramics, sintering electronics parts, fusing glass components |

Upgrade your thermal processing with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs—whether in analytical chemistry, metallurgy, or materials R&D. Contact us today to discuss how we can enhance your lab's efficiency and precision!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a stainless steel reactor function within a muffle furnace for PET to graphene? Master Carbon Synthesis

- What role does a muffle furnace play in analyzing the combustion residues? Optimize Your Composite Char Analysis

- What role does a muffle furnace play in the conversion of S-1@TiO2? Achieve Precision Calcination of Nanospheres

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- What is the primary use of a muffle furnace in the assembly of side-heated resistive gas sensors? Expert Annealing Guide