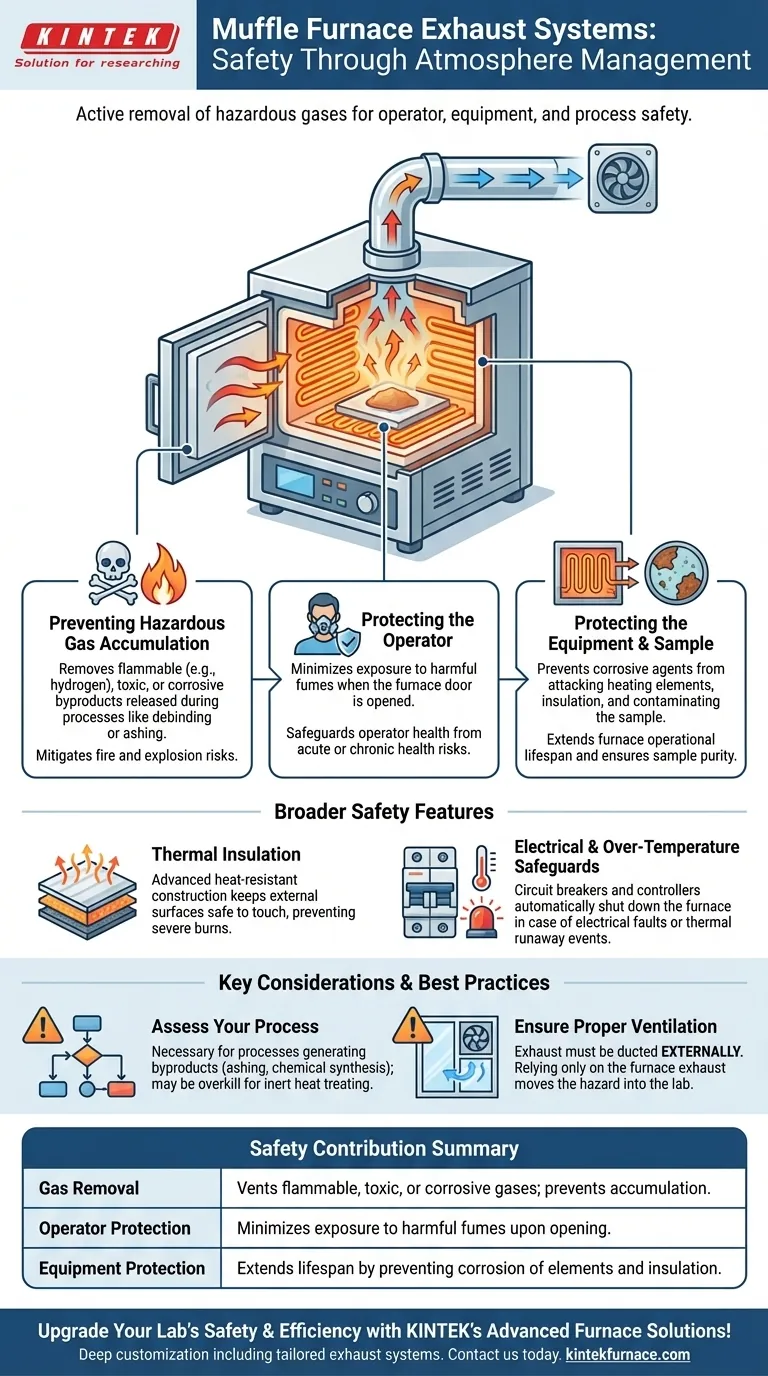

At its core, the exhaust system in a muffle furnace serves a critical safety function by actively removing potentially hazardous gases generated during high-temperature processes. This prevents the accumulation of flammable, corrosive, or toxic byproducts within the sealed chamber, safeguarding both the operator and the equipment itself.

The primary safety role of an exhaust system is to manage the atmosphere inside the furnace. By venting process byproducts, it mitigates the risks of fire, explosion, and exposure to harmful fumes that would otherwise be trapped.

The Core Function: Managing Process Byproducts

Many high-temperature applications are not merely about heating an object; they involve chemical transformations that release gaseous byproducts. The exhaust system is the primary tool for managing these emissions.

Preventing Hazardous Gas Accumulation

Certain processes, like debinding polymers or ashing organic materials, release significant volumes of fumes. If not vented, these can accumulate.

Gases like hydrogen, used in reduction processes, are highly flammable. An exhaust system is essential to prevent concentrations from reaching explosive levels inside the furnace.

Similarly, other chemical reactions can release toxic or corrosive fumes that pose a direct health risk to operators if they escape the chamber upon opening the door.

Protecting the Furnace and Sample

Some gaseous byproducts are highly corrosive. They can attack and degrade the furnace's internal insulation and, more critically, the heating elements.

By continuously removing these corrosive agents, an exhaust system extends the operational lifespan of the furnace and prevents premature failure. This also ensures the purity of the sample is not compromised by a contaminated atmosphere.

A Broader View of Muffle Furnace Safety

While the exhaust system is critical for processes that generate fumes, it is just one component of a comprehensive safety design. Understanding the full system provides a complete picture of risk mitigation.

Thermal Insulation and Operator Protection

The "muffle" itself—the insulated chamber—is a foundational safety feature. It contains extreme heat and separates the heating elements from the workload.

Modern furnaces use advanced heat-resistant construction and multiple layers of insulation to keep the external surfaces at a safe temperature, protecting operators from severe burns.

Electrical and Over-Temperature Safeguards

Circuit breakers and fuses are standard features that protect the system from electrical shorts or power surges, immediately cutting power to prevent electrical fires or catastrophic damage.

Sophisticated temperature controllers do more than just regulate the process; they include over-temperature protection that automatically shuts down the furnace if it exceeds a safe maximum, preventing a thermal runaway event.

Common Pitfalls to Avoid

Understanding a feature also means knowing its limitations and when it is—or is not—necessary.

Assuming All Processes Need an Exhaust

An exhaust system is only necessary if your process generates byproducts. For simple heat treating or annealing of clean, inert metals or ceramics, an exhaust may be unnecessary complexity.

Neglecting Room Ventilation

A furnace exhaust vents gases out of the furnace, but they must be directed to a safe location. The exhaust must be properly ducted to the outside of the building. Relying on an exhaust without proper external ventilation simply moves the hazard from the furnace into the lab.

Making the Right Choice for Your Application

The need for an exhaust system is dictated entirely by the materials you are processing.

- If your primary focus is ashing, debinding, or chemical synthesis: An integrated exhaust system is a non-negotiable safety requirement to handle the resulting fumes.

- If your primary focus is heat-treating clean metals or firing inert ceramics: An exhaust may not be necessary, but you must ensure the work area has excellent general ventilation.

Ultimately, a safe process is one where the equipment's features are correctly matched to the potential risks of the application.

Summary Table:

| Aspect | Safety Contribution |

|---|---|

| Gas Removal | Vents flammable, toxic, or corrosive gases to prevent accumulation and reduce explosion risks. |

| Operator Protection | Minimizes exposure to harmful fumes upon furnace opening, safeguarding health. |

| Equipment Protection | Extends furnace lifespan by preventing corrosion of heating elements and insulation. |

| Process Suitability | Essential for processes like ashing and debinding; not needed for inert material heating. |

Upgrade your lab's safety and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, including tailored exhaust systems to mitigate hazards. Contact us today to discuss how we can enhance your operations and protect your team!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis