In short, a muffle furnace is a specific type of laboratory furnace. The term "laboratory furnace" is a general category for high-temperature ovens used in a lab, and the muffle furnace is a specialized version within that category. Its defining feature is a chamber, or "muffle," that isolates the material being heated from the heating elements and any external contaminants.

A muffle furnace's primary purpose is not just to generate high temperatures, but to do so in an exceptionally clean and controlled environment. It achieves this by using an indirect heating method, ensuring the sample's purity is maintained throughout the process.

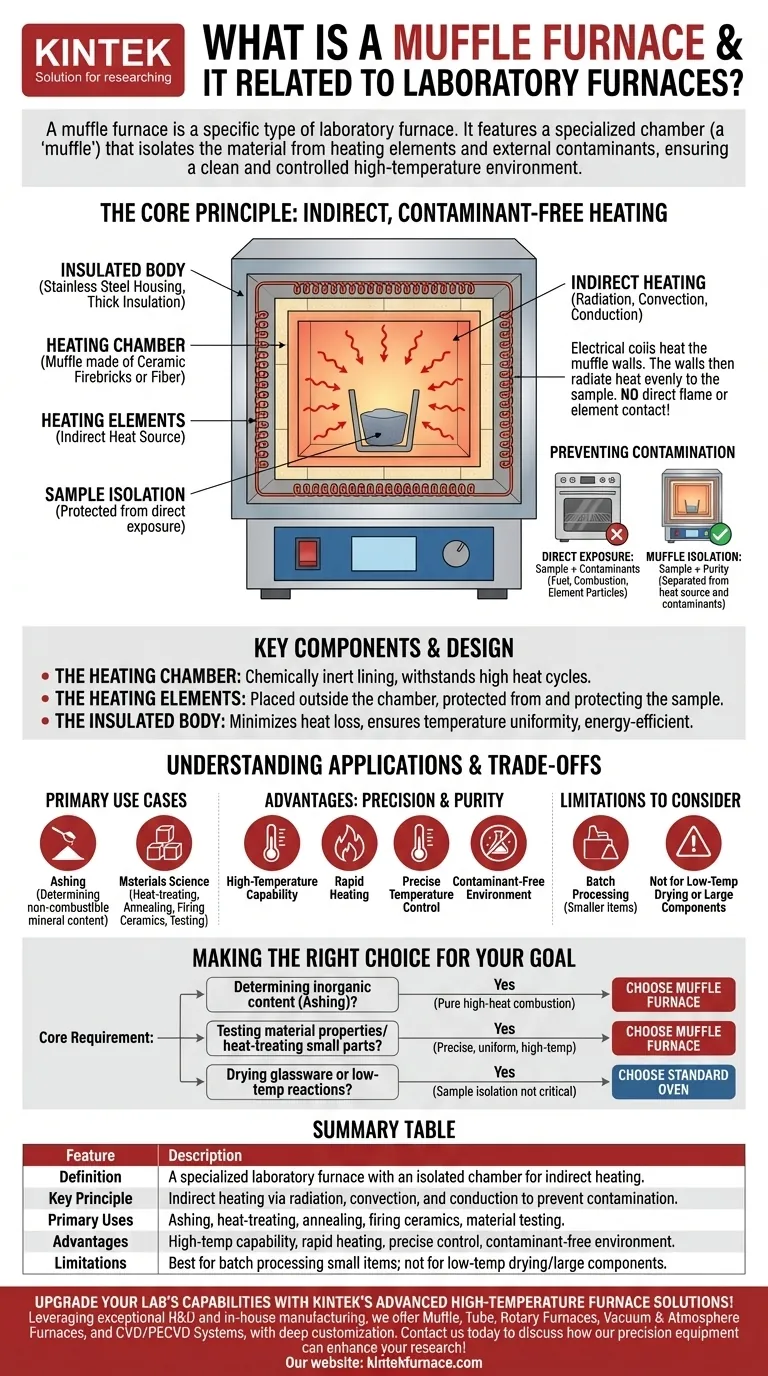

The Core Principle: Indirect, Contaminant-Free Heating

A standard oven or furnace might expose a sample to direct flames or heating coils. A muffle furnace is engineered specifically to prevent this, which is critical for many scientific and analytical procedures.

What is the "Muffle"?

The term muffle refers to the furnace's inner chamber, which is constructed from a hard, heat-resistant material like high-purity ceramic firebricks or fiber.

This chamber acts as a physical barrier. It separates the contents of the furnace from the actual heating elements, which are typically embedded within or wrapped around the chamber walls.

How Heat is Transferred

Because the sample never touches the heating source, the furnace relies on indirect heating.

The process works in sequence:

- Electrical energy powers the heating coils.

- The coils heat the walls of the muffle chamber.

- The hot chamber walls then radiate heat evenly into the sample through a combination of radiation, convection, and conduction.

This method ensures uniform, high-temperature heating without hot spots or direct exposure to electrical components.

Preventing Sample Contamination

The isolation provided by the muffle is the furnace's most important feature for laboratory work.

By separating the sample, it is protected from all potential contaminants, including fuel, combustion gases, or particles shed from the heating elements themselves. This is essential for applications where the chemical composition of the sample must remain unchanged.

Key Components and Design

Muffle furnaces are designed for efficiency and precision at extremely high temperatures. Their construction reflects these goals.

The Heating Chamber

The chamber is lined with dense firebricks or ceramic fiber insulation that can withstand constant high heat cycles while remaining chemically inert.

The Heating Elements

High-temperature heating coils are placed outside the primary chamber, often within the insulating walls. This protects the elements from any potential outgassing from the sample and protects the sample from the elements.

The Insulated Body

To reach and maintain temperatures efficiently, the furnace body contains thick layers of insulation. This minimizes heat loss, improves temperature uniformity, and makes the unit more energy-efficient. The outer housing is typically made of stainless steel for durability.

Understanding the Applications and Trade-offs

While powerful, a muffle furnace is a specialized tool. Understanding its strengths and weaknesses is key to using it correctly.

Primary Use Cases

The unique design makes it ideal for sensitive thermal processes like ashing, where a sample is burned to determine its non-combustible mineral content.

It is also widely used in materials science for heat-treating, annealing metals, firing ceramics, and testing material characteristics at precise, elevated temperatures.

Advantages: Precision and Purity

The main benefits are high-temperature capability, rapid heating, precise temperature control, and most importantly, a contaminant-free environment.

Limitations to Consider

A muffle furnace is not a general-purpose oven. It is designed for batch processing of smaller items at very high temperatures. It is less suitable for low-temperature drying or for processes involving very large components that would not fit in its compact chamber.

Making the Right Choice for Your Goal

To decide if a muffle furnace is the correct instrument, consider the core requirement of your task.

- If your primary focus is determining the inorganic content of a sample (ashing): The muffle furnace is the industry-standard tool because it provides pure, high-heat combustion without contamination.

- If your primary focus is testing material properties or heat-treating small parts: The precise, uniform, and high-temperature environment of a muffle furnace is ideal for reliable results.

- If your primary focus is simply drying glassware or running low-temperature chemical reactions: A standard laboratory oven is a more appropriate and cost-effective choice, as sample isolation is not a critical factor.

Ultimately, choosing a muffle furnace is a decision to prioritize sample purity and temperature precision above all else.

Summary Table:

| Feature | Description |

|---|---|

| Definition | A specialized laboratory furnace with an isolated chamber for indirect heating. |

| Key Principle | Indirect heating via radiation, convection, and conduction to prevent contamination. |

| Primary Uses | Ashing, heat-treating, annealing, firing ceramics, and material testing. |

| Advantages | High-temperature capability, rapid heating, precise control, contaminant-free environment. |

| Limitations | Best for batch processing of small items; not ideal for low-temperature drying or large components. |

Upgrade your lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique experimental needs. Contact us today to discuss how our precision equipment can enhance your research and ensure contaminant-free results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control