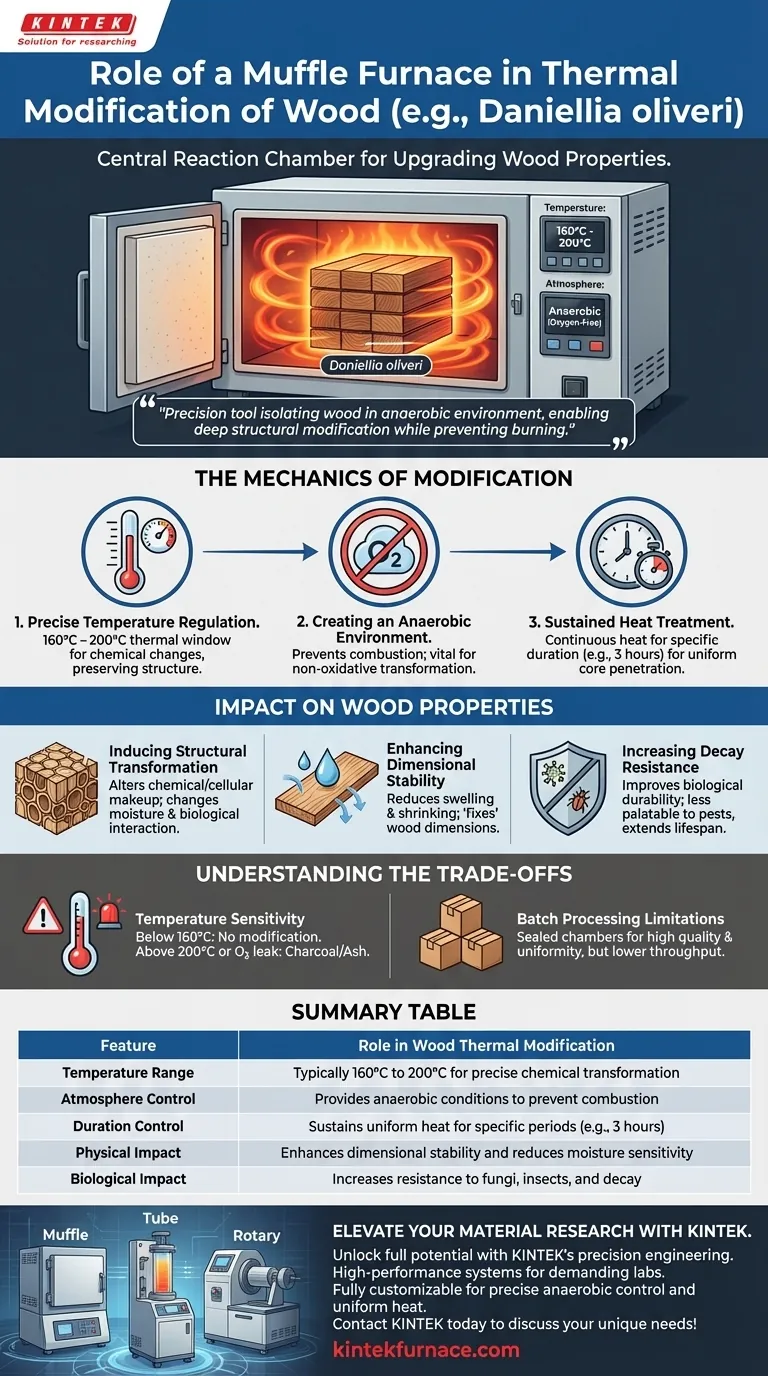

The Muffle Furnace acts as the central reaction chamber for the thermal modification of wood species like Daniellia oliveri. It provides a strictly controlled, high-temperature environment—typically between 160°C and 200°C—allowing the wood to undergo necessary chemical changes without combusting. By maintaining these temperatures under anaerobic (oxygen-free) conditions for a set duration, the furnace facilitates a transformation that significantly upgrades the wood's physical properties.

The Muffle Furnace is not merely a heating element; it is a precision tool that isolates the wood in an anaerobic environment, enabling deep structural modification while preventing the material from burning or degrading.

The Mechanics of Modification

Precise Temperature Regulation

The primary function of the Muffle Furnace is to maintain a specific thermal window, generally ranging from 160°C to 200°C.

This specific range is critical because it is high enough to induce chemical changes but low enough to preserve the structural integrity of the wood.

Creating an Anaerobic Environment

Unlike standard ovens that may circulate air, the Muffle Furnace is designed to operate under anaerobic conditions.

This lack of oxygen is vital for wood modification; it prevents the wood from oxidizing or catching fire at the high processing temperatures required for treatment.

Sustained Heat Treatment

The furnace is responsible for maintaining continuous heat for a specific duration, such as three hours.

This duration ensures the heat penetrates the core of the Daniellia oliveri, ensuring the modification is uniform throughout the timber rather than just on the surface.

Impact on Wood Properties

Inducing Structural Transformation

The heat provided by the furnace drives essential structural and chemical transformations within the wood's cellular makeup.

These changes alter how the wood interacts with moisture and biological agents, fundamentally changing its raw characteristics.

Enhancing Dimensional Stability

One of the primary goals of using a Muffle Furnace is to "fix" the wood dimensions.

By altering the wood's chemical structure, the process reduces the wood's tendency to swell or shrink in response to environmental humidity.

Increasing Decay Resistance

The thermal modification process significantly improves the biological durability of the material.

The treated wood becomes less palatable to fungi and insects, extending the lifespan of Daniellia oliveri in practical applications.

Understanding the Trade-offs

Temperature Sensitivity

The Muffle Furnace must be calibrated with extreme precision.

If temperatures drop below 160°C, the chemical modification may not occur; if they exceed 200°C or if oxygen leaks in, the wood effectively turns into charcoal or ash.

Batch Processing Limitations

Because Muffle Furnaces are often sealed chambers used for precise control, they are typically batch-process oriented.

This ensures high quality and uniformity but may limit throughput compared to continuous, open-air heating methods used for less critical drying processes.

Making the Right Choice for Your Goal

To ensure successful thermal modification of Daniellia oliveri, consider the following operational priorities:

- If your primary focus is Material Durability: Ensure the furnace maintains a strict anaerobic seal to maximize chemical transformation without degradation.

- If your primary focus is Process Consistency: Prioritize a furnace with high-quality insulation (the "muffle") to prevent heat escape and ensure uniform temperature distribution during the three-hour holding period.

Precise control of the thermal environment is the single most important factor in upgrading wood from a raw resource to a high-performance material.

Summary Table:

| Feature | Role in Wood Thermal Modification |

|---|---|

| Temperature Range | Typically 160°C to 200°C for precise chemical transformation |

| Atmosphere Control | Provides anaerobic (oxygen-free) conditions to prevent combustion |

| Duration Control | Sustains uniform heat for specific periods (e.g., 3 hours) |

| Physical Impact | Enhances dimensional stability and reduces moisture sensitivity |

| Biological Impact | Increases resistance to fungi, insects, and decay |

Elevate Your Material Research with KINTEK

Unlock the full potential of your thermal modification processes with KINTEK’s precision engineering. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the most demanding lab environments.

Whether you are upgrading wood species like Daniellia oliveri or developing advanced materials, our fully customizable high-temperature furnaces ensure the precise anaerobic control and uniform heat distribution you need for consistent, high-quality results.

Ready to optimize your thermal processing? Contact KINTEK today to discuss your unique needs!

Visual Guide

References

- Issah Chakurah, Enoch Gbapenuo Tampori. The Effect of Thermal Modification on Anatomical Properties of Daniellia oliveri (Rolfe) Hutch and Dalziel from Ghana. DOI: 10.5552/drvind.2025.0218

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the function of a high-temperature muffle furnace in the determination of ash and crude fiber? Expert Analysis

- What makes uniform heating important in a muffle furnace? Ensure Precise, Reliable Results Every Time

- What is the primary application of a laboratory muffle furnace in the preparation of Co2SnO4 nanocubes? Expert Guide

- What role does a high-temperature muffle furnace play in the component analysis of Moringa oleifera seeds?

- What industries commonly use muffle furnaces? Essential for Labs, Metallurgy, and More

- How does a high-temperature Muffle Furnace facilitate the conversion of precursors into spinel-type NiCo2O4?

- What is the function of a high-temperature box resistance furnace? Optimize Hierarchical Zeolite Synthesis

- How do high-precision heating furnaces ensure quality during high-temperature capillary imprinting? | KINTEK