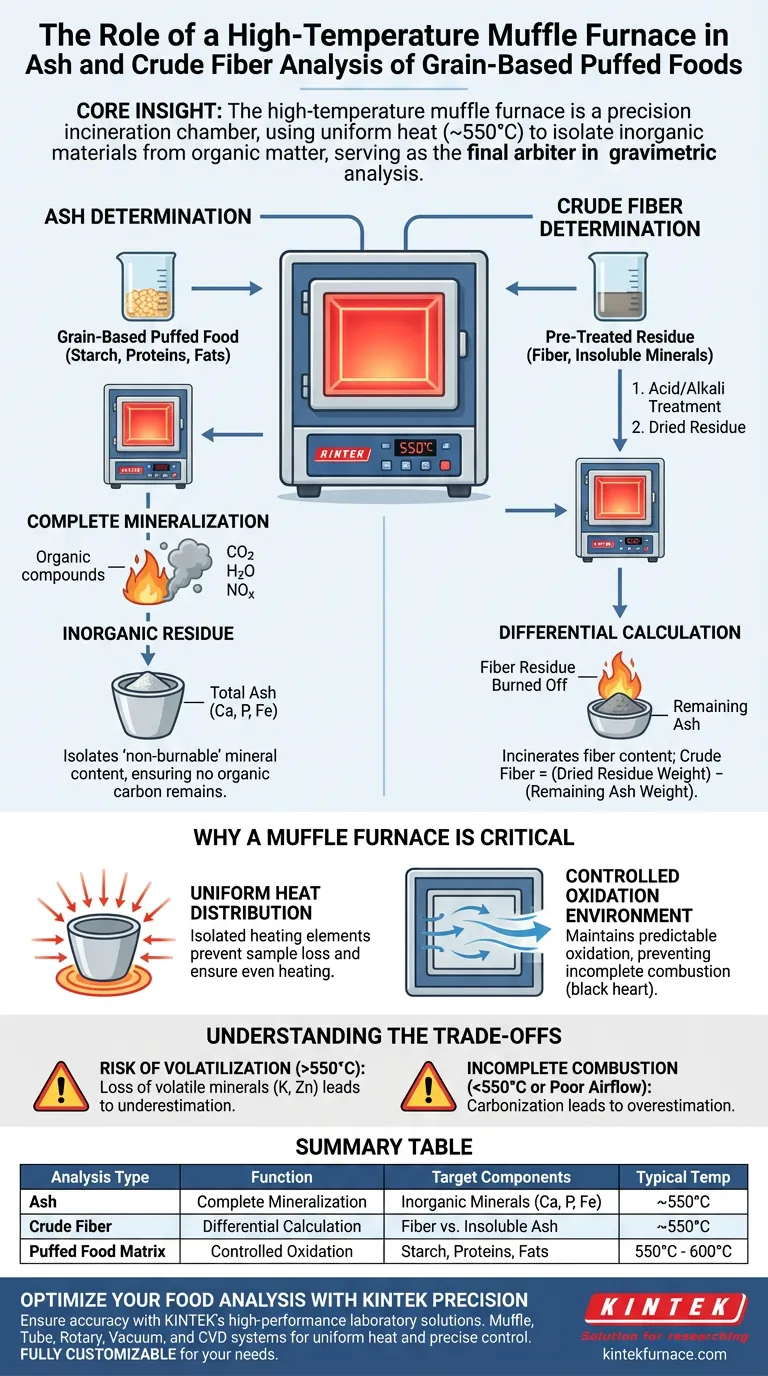

The high-temperature muffle furnace functions as a precise incineration chamber, utilizing extreme heat to isolate inorganic materials from organic matter. In the analysis of grain-based puffed foods, it serves two distinct purposes: completely oxidizing organic components to measure total ash, and burning off organic residues to calculate crude fiber content via mass loss.

Core Insight The muffle furnace isolates the "non-burnable" mineral content of a sample by applying uniform heat, typically up to 550°C. It acts as the final arbiter in gravimetric analysis—whether you are measuring what remains (ash) or what was lost during combustion (crude fiber).

The Role in Ash Determination

Complete Mineralization

The primary function of the furnace during ash analysis is mineralization. Grain-based puffed foods contain starch, proteins, and fats. The furnace heats the sample to approximately 550°C, a temperature sufficient to oxidize these organic compounds into gases (carbon dioxide, water vapor, and nitrogen oxides).

Isolation of Inorganic Residue

Once the organic matter is removed, only the inorganic minerals remain. This residue represents the total mineral content (such as calcium, phosphorus, and iron) of the food product. The stable environment of the muffle furnace ensures that no organic carbon remains to skew the weight of these minerals.

The Role in Crude Fiber Determination

Processing Pre-Treated Residues

Unlike ash determination, crude fiber analysis does not involve placing the raw food directly into the furnace. The sample first undergoes acid and alkali treatments to dissolve digestible carbohydrates and proteins. The furnace is used to process the remaining dried residue, which consists of fiber and insoluble minerals.

Differential Calculation

The furnace performs a gravimetric difference measurement. By incinerating the fiber residue, the furnace burns away the actual fiber content, leaving only the ash behind. The crude fiber content is calculated by subtracting the weight of the remaining ash from the weight of the dried residue before incineration.

Why a "Muffle" Furnace is Critical

Uniform Heat Distribution

A defining feature of a muffle furnace is that the heating elements are isolated from the chamber (the "muffle"). This ensures the sample is heated by radiant energy rather than direct contact or convection currents. For puffed foods, which can be lightweight and prone to scattering, this prevents physical loss of the sample during heating.

Controlled Oxidation Environment

The furnace maintains a constant, high-temperature oxidative atmosphere. This consistency is vital for reproducibility. It ensures that the chemical breakdown of the grain matrix occurs at a predictable rate, preventing the formation of "black heart" (incomplete combustion) which would result in inaccurate data.

Understanding the Trade-offs

The Risk of Volatilization

While high heat is necessary, excessive temperatures can introduce errors. If the furnace exceeds the recommended 550°C for grain products (approaching the 600°C+ used for other materials), certain volatile minerals (like potassium or zinc) may vaporize and be lost. This leads to an underestimation of ash content.

Incomplete Combustion

Conversely, if the temperature drops or air circulation is insufficient, organic matter may carbonize (turn to charcoal) rather than oxidize completely to ash. This results in an overestimation of the mineral content, as carbon weight is falsely counted as mineral weight.

Making the Right Choice for Your Goal

To ensure accurate results when analyzing grain-based puffed foods, apply the specific protocol relevant to your target metric:

- If your primary focus is Total Ash: Ensure the furnace is set to 550°C to completely remove all organic matter without volatilizing the minerals.

- If your primary focus is Crude Fiber: Use the furnace only after chemical digestion steps to burn off the fiber, measuring the weight loss to determine the final value.

Success in this analysis relies on using the furnace not just as a heater, but as a precision tool for isolating mass through controlled oxidation.

Summary Table:

| Analysis Type | Function of Muffle Furnace | Target Components | Typical Temperature |

|---|---|---|---|

| Ash Determination | Complete Mineralization | Inorganic minerals (Ca, P, Fe) | ~550°C |

| Crude Fiber | Differential Calculation | Fiber vs. Insoluble Ash | ~550°C |

| Puffed Food Matrix | Controlled Oxidation | Starch, proteins, and fats | 550°C - 600°C |

Optimize Your Food Analysis with KINTEK Precision

Ensure the accuracy of your ash and fiber measurements with KINTEK’s high-performance laboratory solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems designed to provide the uniform heat distribution and precise temperature control essential for food science and grain analysis.

Our laboratory high-temperature furnaces are fully customizable to meet your unique research or production needs, preventing volatilization and ensuring complete combustion every time.

Ready to elevate your lab's efficiency? Contact us today to find the perfect furnace solution!

Visual Guide

References

- Proximate composition of millet-based extruded products for healthier snacking. DOI: 10.33545/2664844x.2025.v7.i5b.387

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the significance of muffle furnaces in research and analysis? Unlock Precise Heat Treatment for Your Lab

- How do Box high-temperature furnaces and thermocouples ensure HP40Nb alloy test precision? Master Thermal Stability

- What role does a high-temperature muffle furnace play in the pre-calcination of PZT ceramics? Essential Synthesis Guide

- How does heat treatment in a muffle furnace affect CuFe2O4–SnO2-rGO? Optimize Heterojunction Composite Performance

- What should be done before using a muffle furnace for the first time or after a long period of inactivity? Essential Pre-Baking Guide

- How do high-temperature furnaces and crucibles work in molten salt carbonization? Master Catalyst Synthesis.

- What are the key features of box type electric furnaces in heat treatment processes? Achieve Precise Thermal Control for Superior Metallurgy

- What are the advantages of considering door opening options in a muffle furnace? Optimize Safety and Efficiency in Your Lab