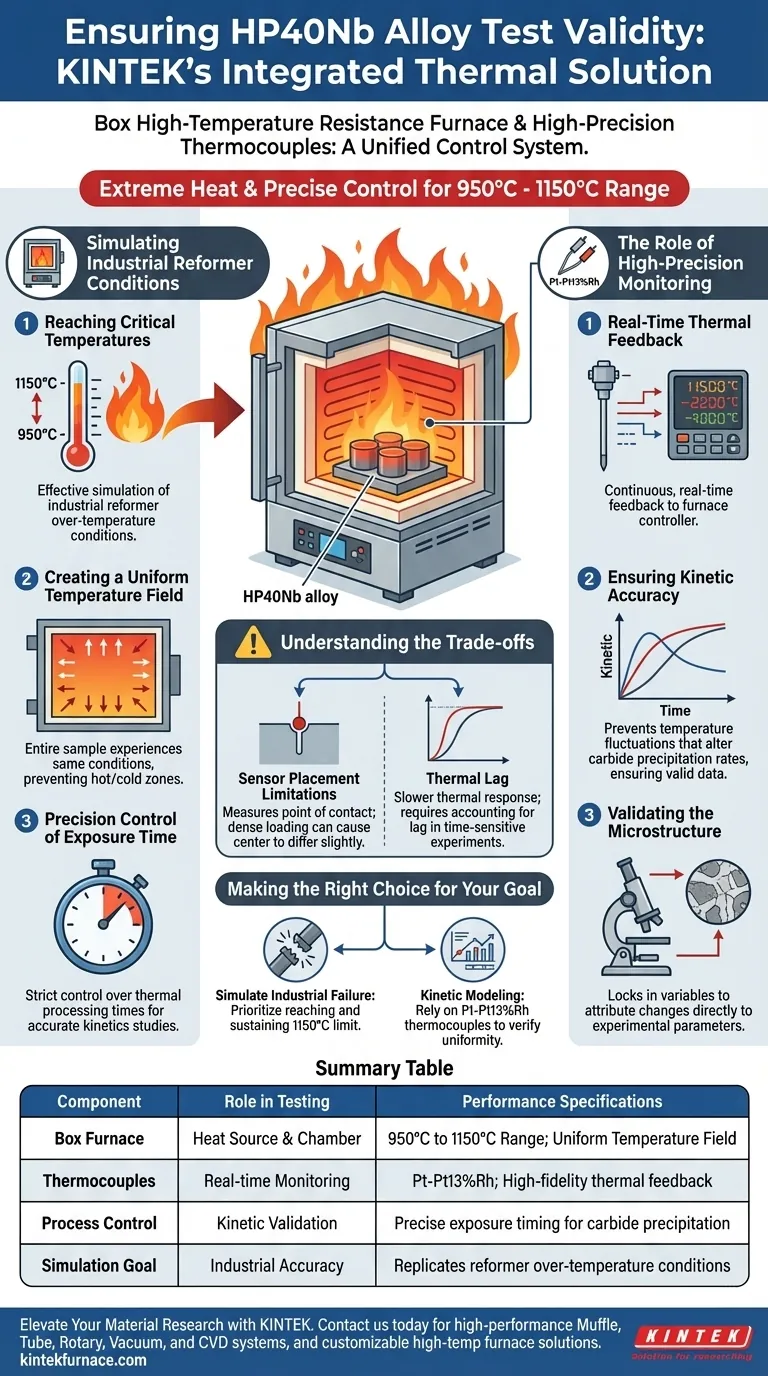

The Box high-temperature resistance furnace and high-precision thermocouples function as a unified control system to guarantee the validity of HP40Nb alloy exposure tests. The furnace generates the extreme heat required to reach the 950°C to 1150°C range, effectively simulating industrial reformer over-temperature conditions. Meanwhile, integrated Pt-Pt13%Rh thermocouples provide real-time monitoring to ensure this heat remains uniform and stable, allowing for precise control over thermal processing times.

Validating metallurgical kinetics requires more than just high heat; it requires thermal stability. By coupling a uniform heating chamber with high-fidelity feedback sensors, researchers can isolate the specific effects of temperature and time on secondary carbide precipitation without experimental variables distorting the data.

Simulating Industrial Reformer Conditions

Reaching Critical Temperatures

To accurately test the HP40Nb alloy, experimental conditions must mimic the harsh environment of industrial reformers. The Box high-temperature resistance furnace is specifically calibrated to operate between 950°C and 1150°C.

Creating a Uniform Temperature Field

Reliable data depends on the entire sample experiencing the exact same conditions simultaneously. The furnace design ensures a uniform temperature field, preventing hot spots or cold zones that could skew the microstructural evolution of the alloy.

Precision Control of Exposure Time

Accurate kinetics studies require exact start and stop times for thermal exposure. The furnace allows for strict control over thermal processing times, ensuring the alloy is exposed to the target temperature for the exact duration intended.

The Role of High-Precision Monitoring

Real-Time Thermal Feedback

The system utilizes Pt-Pt13%Rh thermocouples, which are specialized sensors designed for high-temperature accuracy. These devices provide continuous, real-time feedback to the furnace controller.

Ensuring Kinetic Accuracy

The primary goal of this setup is to study the kinetics of secondary carbide precipitation and decomposition. Any fluctuation in temperature would alter the rate of these chemical reactions, rendering the data invalid.

Validating the Microstructure

By locking in the temperature variables, researchers can attribute any observed changes in the alloy directly to the experimental parameters. This ensures the resulting microstructure is a true representation of the alloy's behavior under stress.

Understanding the Trade-offs

Sensor Placement Limitations

While thermocouples provide high-precision data, they only measure temperature at the specific point of contact or insertion. If the furnace loading is too dense, the temperature reading at the sensor may differ slightly from the temperature at the center of a sample mass.

Thermal Lag

Resistance furnaces provide excellent stability, but they often have a slower thermal response compared to other heating methods. This means there is a "lag" between adjusting the settings and achieving the new equilibrium, which must be accounted for in time-sensitive experiments.

Making the Right Choice for Your Goal

To ensure your experimental setup yields valid metallurgical data, consider your specific objectives:

- If your primary focus is simulating industrial failure: Prioritize the furnace's ability to reach and sustain the upper limit of 1150°C to mimic extreme over-temperature events.

- If your primary focus is kinetic modeling: Rely on the Pt-Pt13%Rh thermocouples to verify the uniformity of the temperature field, as even minor gradients will corrupt kinetic calculations.

Success in high-temperature alloy testing is defined not by how hot you can get the material, but by how precisely you can control that heat over time.

Summary Table:

| Component | Role in Testing | Performance Specifications |

|---|---|---|

| Box Furnace | Heat Source & Chamber | 950°C to 1150°C Range; Uniform Temperature Field |

| Thermocouples | Real-time Monitoring | Pt-Pt13%Rh; High-fidelity thermal feedback |

| Process Control | Kinetic Validation | Precise exposure timing for carbide precipitation |

| Simulation Goal | Industrial Accuracy | Replicates reformer over-temperature conditions |

Elevate Your Material Research with KINTEK

Precision in metallurgical kinetics demands more than just heat—it requires an integrated thermal solution. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized lab furnaces designed to meet the rigorous demands of alloy exposure tests.

Whether you need custom temperature profiles for industrial simulation or high-precision sensors for kinetic modeling, our systems provide the stability and control your data depends on. Contact us today to find your customizable high-temp furnace solution.

Visual Guide

References

- Milica Timotijević, Dragan Rajnović. Insight to the Microstructure Analysis of a HP Austenitic Heat-Resistant Steel Under Short-Term High-Temperature Exposure. DOI: 10.3390/met15050486

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a laboratory high-temperature box furnace influence the microstructure of H13 steel? Expert Insights

- What core function does a muffle furnace serve in superconducting material synthesis? Master Solid-State Reactions

- How is a muffle furnace utilized to determine the thermal stability of NaA zeolite? Expert Stress-Test Analysis

- How does a high-temperature muffle furnace facilitate the formation of mixed-phase TiO2 nanofillers? Phase Control Guide

- Why is a laboratory box resistance furnace essential for simulating long-term high-temperature oxidation exposure?

- What is the maximum temperature of the muffle furnace described? Key Limits for Lab Success

- What is the temperature of a sintering oven? Master Material-Specific Thermal Cycles

- What are some common processes that use muffle furnaces? Achieve Pure, Controlled High-Temperature Applications