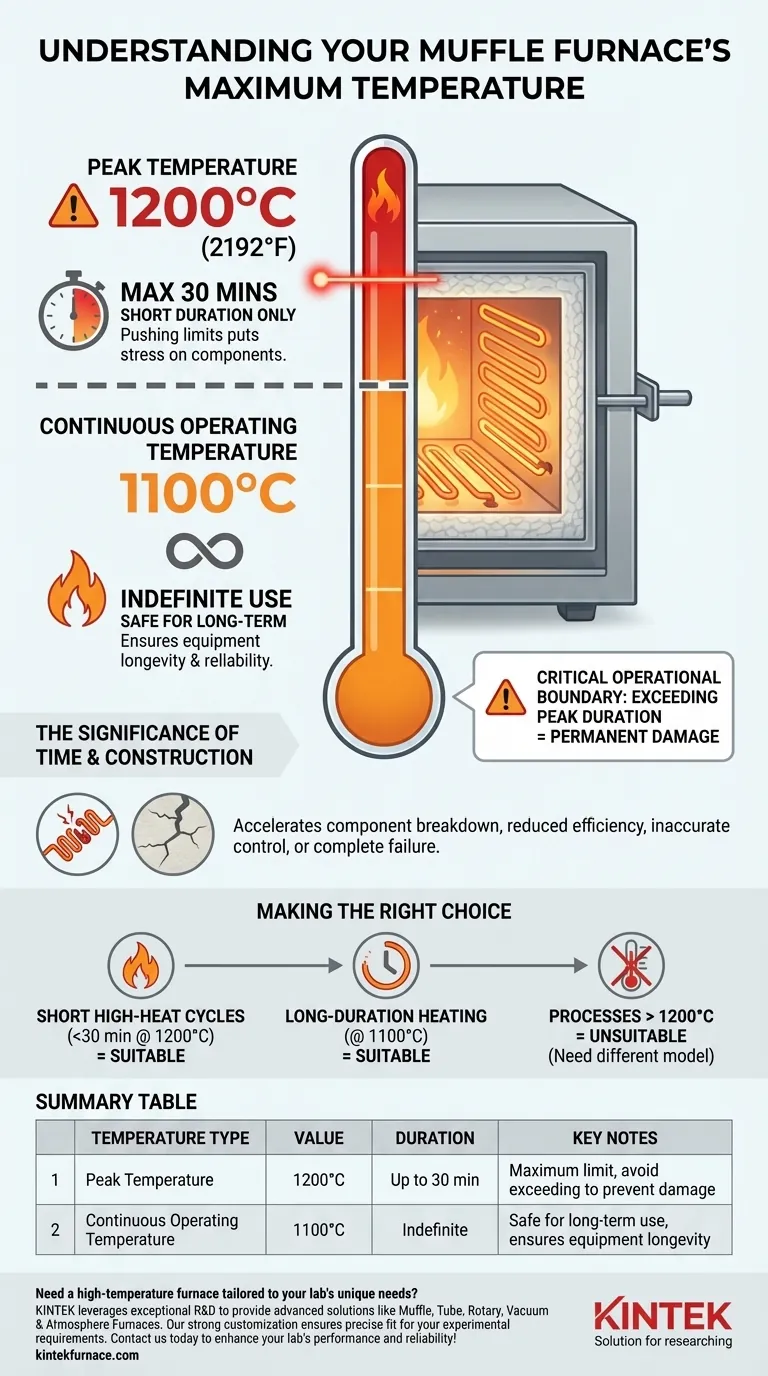

The maximum temperature for the specific muffle furnace described is 1200°C (2192°F). However, this peak temperature can only be maintained for a short duration of up to 30 minutes. The furnace's maximum temperature for continuous, long-term operation is lower, at 1100°C.

Understanding the difference between a furnace's temporary peak temperature and its sustainable continuous operating temperature is the single most important factor in ensuring both the success of your application and the longevity of the equipment.

Understanding Furnace Temperature Ratings

A furnace's temperature specification is more than a single number. It represents a set of operational limits defined by the physical constraints of its components, such as the heating elements and insulation.

Peak Temperature vs. Continuous Operating Temperature

The most critical distinction is between peak and continuous temperature.

Peak Temperature (1200°C for this model) is the absolute maximum the furnace can achieve for a brief period. Pushing the equipment to this limit places significant stress on the heating elements and internal materials.

Continuous Operating Temperature (1100°C for this model) is the maximum temperature the furnace can safely maintain for extended or indefinite periods without risking accelerated degradation or failure.

The Significance of Time Limits

The 30-minute time limit at 1200°C is not an arbitrary suggestion; it is a critical operational boundary.

Exceeding this duration at peak temperature can cause permanent damage to the heating elements, leading to reduced efficiency, inaccurate temperature control, or complete failure. It also accelerates the breakdown of the furnace's refractory ceramic insulation.

The Role of Furnace Construction

A muffle furnace is an insulated box containing a high-temperature chamber, or "muffle." This design protects the heated materials from direct contact with the heating elements.

The materials used for the heating elements and the firebrick or ceramic fiber insulation are what dictate the furnace's ultimate temperature limits.

Interpreting Conflicting Specifications

When reviewing technical data, it's common to encounter conflicting information. The key is to prioritize specific data over general statements.

Addressing the 1700°C Anomaly

One reference mentions a maximum temperature of 1700°C. Given the multiple, specific references confirming a 1200°C limit for this unit, the 1700°C figure should be considered an error or, more likely, a reference to a different, higher-specification model.

Muffle furnaces are available in a wide range of capabilities, from common 1200°C models to specialized units that can exceed 1800°C.

Why Model-Specific Data is Critical

Always operate equipment based on the manufacturer's nameplate and official manual for that specific model. General marketing descriptions or data for similar-looking units are not reliable for determining safe operational limits.

The consistent reports of a 1200°C peak and 1100°C continuous temperature provide a clear, reliable operational profile for this specific furnace.

Making the Right Choice for Your Application

To use this equipment correctly, align your process requirements with its stated capabilities.

- If your primary focus is short, high-heat cycles: This furnace is suitable for processes requiring temperatures up to 1200°C, as long as each cycle is less than 30 minutes.

- If your primary focus is long-duration heating or annealing: Your maximum reliable operating temperature for this furnace is 1100°C.

- If your primary focus is processes requiring over 1200°C: This specific furnace is not suitable, and you must use a different model explicitly rated for higher continuous temperatures.

Always verify your process requirements against the furnace's specific continuous and peak temperature ratings to ensure safety, reliability, and valid results.

Summary Table:

| Temperature Type | Value | Duration | Key Notes |

|---|---|---|---|

| Peak Temperature | 1200°C | Up to 30 min | Maximum limit, avoid exceeding to prevent damage |

| Continuous Operating Temperature | 1100°C | Indefinite | Safe for long-term use, ensures equipment longevity |

Need a high-temperature furnace tailored to your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your experimental requirements. Contact us today to enhance your lab's performance and reliability!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals