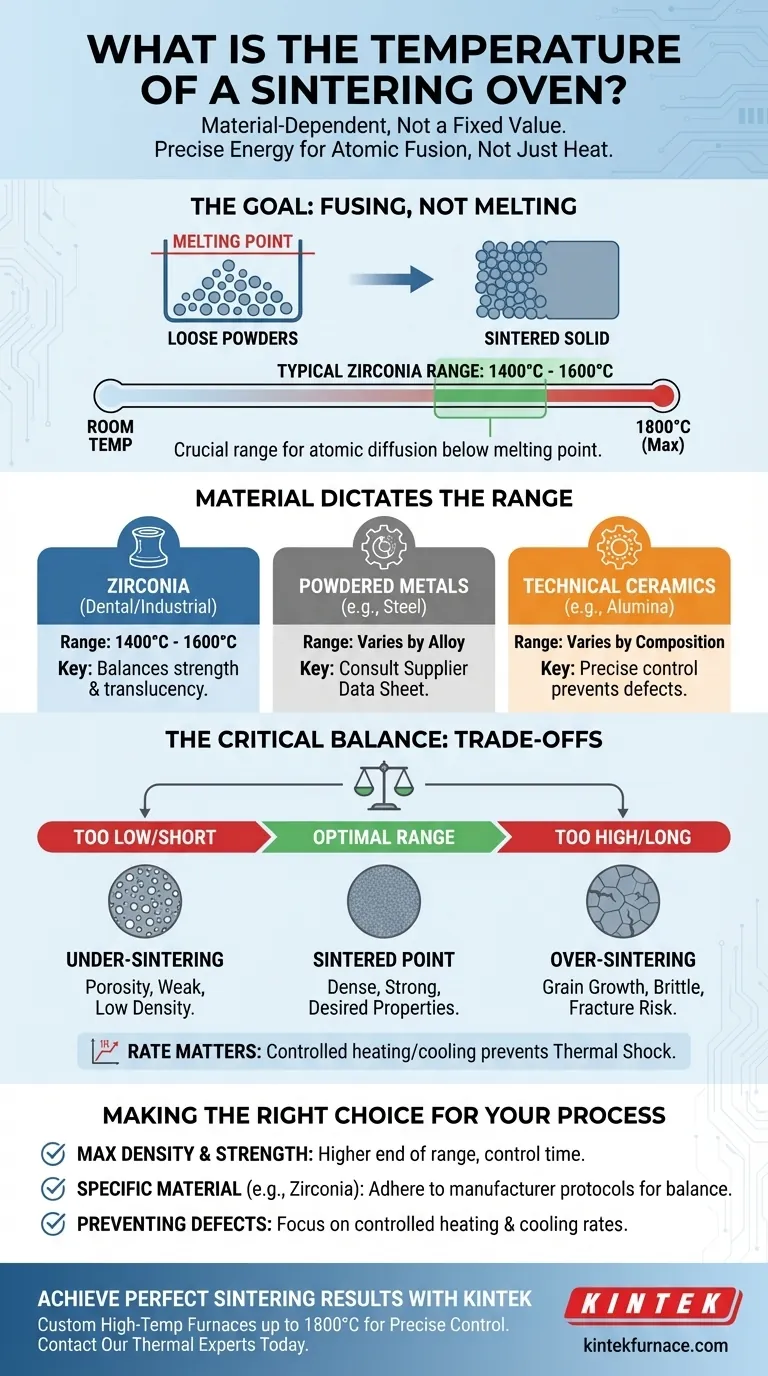

The temperature of a sintering oven is not one fixed value but is a highly specific parameter that depends entirely on the material being processed. While some high-temperature furnaces can reach up to 1800°C (3272°F), a typical operating range for sintering common materials like zirconia is between 1400°C and 1600°C. The correct temperature is crucial for achieving the desired final properties of the material.

The critical takeaway is that a sintering oven's temperature is dictated by the material inside it. The goal is not simply to reach a high temperature, but to supply the precise thermal energy needed to fuse particles into a dense, solid component without melting them.

Why Temperature Is the Critical Variable

To understand sintering, you must see temperature not as a setting, but as the energy source driving a physical transformation. The goal is to achieve specific material properties, not just to heat something up.

The Goal: Fusing Particles into a Solid Mass

Sintering is a process where powdered material is heated to fuse individual particles together, forming a solid, dense object.

Crucially, this happens below the material's melting point. The heat provides enough energy for atoms to migrate across the boundaries of the particles, bonding them into a coherent piece.

Reaching the "Sintering Point"

Every material has a "sintering point" or range. This is the temperature at which atomic diffusion becomes significant enough to cause densification.

Going above this range risks melting the material, which destroys the fine-grained structure you are trying to create. Staying below it results in an under-sintered, porous, and weak part.

Temperature's Effect on Material Properties

The specific temperature within the correct range directly influences the final properties of the component.

Higher temperatures generally lead to faster and more complete densification, resulting in a stronger, less porous part. However, this comes with risks that must be managed.

Material Dictates the Temperature Range

There is no universal sintering temperature because every material behaves differently. The oven is simply a tool; the material's composition dictates how that tool is used.

Case Study: Zirconia

Zirconia, a ceramic widely used in dental crowns and industrial applications, is a perfect example.

It is typically sintered between 1400°C and 1600°C. This specific range is designed to maximize its strength and fracture toughness while also achieving the desired level of translucency, a key aesthetic requirement for dental use.

Other Materials, Other Temperatures

This principle applies universally. Powdered metals like steel or titanium have their own unique sintering windows, which are different from those for ceramics like alumina or silicon carbide.

The furnace's capability, such as a maximum of 1800°C, simply indicates its ability to handle a wide variety of high-performance materials.

Understanding the Trade-offs

Choosing a sintering temperature is a balance. Simply using the highest possible temperature is often a mistake.

The Risk of Over-Sintering

If the temperature is too high or the part is held at that temperature for too long, a phenomenon called grain growth can occur.

While the part becomes dense, the internal crystalline grains grow larger, which can paradoxically make the material more brittle and prone to fracture.

The Problem of Under-Sintering

If the temperature is too low or the cycle is too short, the particles will not fully fuse.

This leaves behind significant porosity (empty spaces) in the final part. The result is a component with poor mechanical strength, low density, and compromised performance.

The Role of Heating and Cooling Rates

The peak temperature is only part of the story. The rate at which the oven heats up and cools down is also critical.

Ramping the temperature too quickly can cause thermal shock, leading to cracks in the material before it's even fully sintered.

Making the Right Choice for Your Process

To determine the correct sintering temperature, you must start with your material and desired outcome. Always consult the material supplier's technical data sheet for the recommended thermal cycle.

- If your primary focus is achieving maximum density and strength: Operate at the higher end of the material's recommended range, but carefully control the time to prevent excessive grain growth.

- If your primary focus is processing a specific material like zirconia: Adhere strictly to the manufacturer's specified temperature protocols (e.g., 1400°C - 1600°C) to balance strength with other critical properties like aesthetics.

- If your primary focus is preventing defects: Pay close attention to the heating and cooling rates, as a controlled ramp is just as important as the peak temperature for ensuring part integrity.

Ultimately, mastering the sintering process is about using temperature as a precise tool to engineer the final properties of your material.

Summary Table:

| Material | Typical Sintering Temperature Range | Key Considerations |

|---|---|---|

| Zirconia | 1400°C - 1600°C | Balances strength with translucency for dental/industrial use |

| Powdered Metals (e.g., Steel) | Varies by alloy | Consult supplier data sheet for specific range |

| Technical Ceramics (e.g., Alumina) | Varies by composition | Requires precise control to prevent grain growth or porosity |

Achieve Perfect Sintering Results with a Customized High-Temperature Furnace

Mastering the sintering process requires a furnace that delivers precise, reliable temperature control tailored to your specific material. KINTEK's advanced high-temperature furnaces, including our Muffle, Tube, and Atmosphere models, are engineered for exacting thermal cycles up to 1800°C.

Our strong in-house R&D and manufacturing capabilities allow for deep customization, ensuring your furnace perfectly matches your unique material requirements—whether you're sintering zirconia for dental applications or specialized metals and ceramics for industrial components.

Ready to engineer superior material properties? Contact our thermal experts today to discuss how a KINTEK sintering solution can optimize your process.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the function of the temperature control system in a box furnace? Achieve Precise Thermal Processing

- How does an electric furnace contribute to energy efficiency? Maximize Your Lab's Heating Performance

- Why is a high-temperature muffle furnace required to convert dolomite into an active catalyst phase? Unlock Reactivity

- How does a precision temperature-controlled sintering furnace ensure the structural quality of PTFE/Fe2O3 composites?

- What are the recommended heating and cooling protocols for a muffle furnace? Ensure Longevity and Safety in Your Lab

- What is the primary purpose of a box furnace? Achieve Precise Heat Treatment for Your Materials

- What role does a muffle furnace play in the solid-state reaction synthesis of Dy4T1-xGa12? Achieve Pure Alloy Phases

- Why is a high-temperature muffle furnace utilized for g-C3N4 nanosheet synthesis? Master Two-Step Thermal Exfoliation