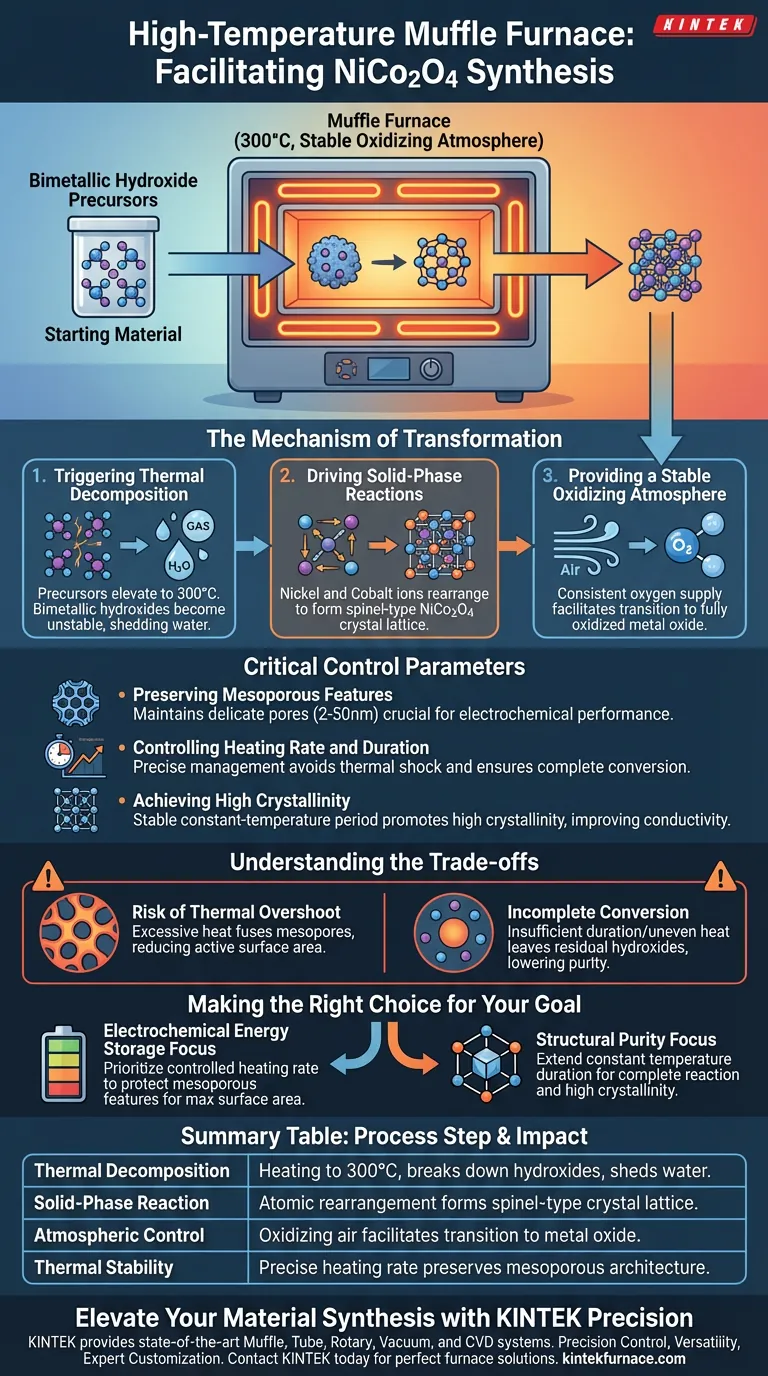

A high-temperature Muffle Furnace facilitates this conversion by maintaining a precisely controlled, stable thermal environment at 300 °C. This specific heat treatment triggers the thermal decomposition of bimetallic hydroxide precursors and drives a simultaneous solid-phase reaction to crystallize the material into the target oxide.

The Muffle Furnace acts as a precision phase-transformation tool, converting raw precursors into spinel-structured NiCo2O4 with high crystallinity while preserving the critical mesoporous architecture needed for electrochemical performance.

The Mechanism of Transformation

Triggering Thermal Decomposition

The primary function of the furnace in this specific application is to elevate the precursors to 300 °C.

At this temperature, the bimetallic hydroxides used as starting materials become thermodynamically unstable.

They undergo thermal decomposition, effectively shedding water molecules and breaking down their initial chemical structure to prepare for reconfiguration.

Driving Solid-Phase Reactions

Once the hydroxides decompose, the furnace’s stable heat drives a solid-phase reaction.

This is where the actual synthesis of the material occurs. Nickel and Cobalt ions rearrange at the atomic level.

This rearrangement forms the specific spinel-type crystal lattice characteristic of NiCo2O4.

Providing a Stable Oxidizing Atmosphere

While the furnace is capable of very high temperatures, its ability to maintain a consistent oxidizing atmosphere (air environment) is vital.

Oxygen from the environment is required to facilitate the transition from a hydroxide precursor to a fully oxidized metal oxide.

Critical Control Parameters

Preserving Mesoporous Features

The utility of NiCo2O4 in energy storage depends heavily on its surface area.

The Muffle Furnace allows for the preservation of mesoporous features (pores between 2 and 50 nm).

If the heating environment were uncontrolled or volatile, these delicate porous structures could collapse, reducing the material's electrochemical effectiveness.

Controlling Heating Rate and Duration

Success depends on more than just reaching the target temperature.

The furnace allows you to precisely manage the heating rate and the holding time (duration) at 300 °C.

This control ensures the conversion is complete without subjecting the material to thermal shock, which could damage the crystal structure.

Achieving High Crystallinity

A stable constant-temperature period ensures the atoms have sufficient time to settle into their lowest energy states.

This results in high crystallinity, which improves the electrical conductivity and stability of the final material.

Understanding the Trade-offs

The Risk of Thermal Overshoot

While the Muffle Furnace provides stability, the specific temperature of 300 °C is relatively low for a "high-temperature" device.

If the temperature is allowed to spike significantly higher, you risk over-sintering.

Over-sintering causes the beneficial mesopores to fuse and close up, drastically reducing the active surface area available for electrochemical reactions.

Incomplete Conversion

Conversely, if the heating duration is insufficient or the heat distribution is uneven, the center of the precursor bulk may not fully react.

This leaves behind residual hydroxides, resulting in a low-purity product with inferior performance characteristics.

Making the Right Choice for Your Goal

To maximize the potential of your NiCo2O4 synthesis, tailor your furnace settings to your specific objective.

- If your primary focus is Electrochemical Energy Storage: Prioritize a controlled heating rate to protect mesoporous features, ensuring maximum surface area for ion transport.

- If your primary focus is Structural Purity: Extend the constant temperature duration at 300 °C to guarantee complete solid-phase reaction and high crystallinity.

By balancing thermal stability with precise time controls, you transform raw chemicals into high-performance energy storage materials.

Summary Table:

| Process Step | Mechanism | Impact on NiCo2O4 |

|---|---|---|

| Thermal Decomposition | Heating to 300 °C | Breaks down hydroxides and sheds water molecules |

| Solid-Phase Reaction | Atomic rearrangement | Forms the characteristic spinel-type crystal lattice |

| Atmospheric Control | Oxidizing air environment | Facilitates transition from hydroxide to metal oxide |

| Thermal Stability | Precise heating rate | Preserves mesoporous architecture for energy storage |

Elevate Your Material Synthesis with KINTEK Precision

High-performance energy materials like NiCo2O4 demand absolute thermal accuracy. KINTEK provides state-of-the-art laboratory solutions tailored for advanced research. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific temperature and atmospheric requirements.

Our Value to You:

- Precision Control: Maintain exact temperatures to preserve delicate mesoporous structures.

- Versatility: Solutions ranging from standard high-temp furnaces to complex CVD systems.

- Expert Customization: Equipment designed to fit your unique experimental parameters.

Don't let thermal overshoot compromise your crystallinity. Contact KINTEK today to find the perfect furnace for your next breakthrough!

Visual Guide

References

- Xiang Zhang. Facile Synthesis of Mesoporous NiCo2O4 Nanosheets on Carbon Fibers Cloth as Advanced Electrodes for Asymmetric Supercapacitors. DOI: 10.3390/nano15010029

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is the intended application important when selecting a muffle furnace? Ensure Precision and Efficiency for Your Lab

- What are the steps to operate a box muffle furnace? Master Safe and Efficient Heating Processes

- What conditions does a muffle furnace provide for Fucus vesiculosus ash determination? Achieve Precise 700°C Ashing

- What is the difference between a muffle furnace and a normal furnace? Choose the Right Tool for Purity vs. Speed

- What role does a muffle furnace play in Al2O3/PTFE composites? Optimize Sintering for Superior Performance

- How is a box resistance furnace or muffle furnace utilized when processing BCZT gel? Expert Powder Synthesis Guide

- Why is a high-temperature muffle furnace required for coal gangue activation? Unlock Maximum Material Reactivity

- What are the temperature capabilities of drying ovens compared to muffle furnaces? Choose the Right Tool for Your Lab