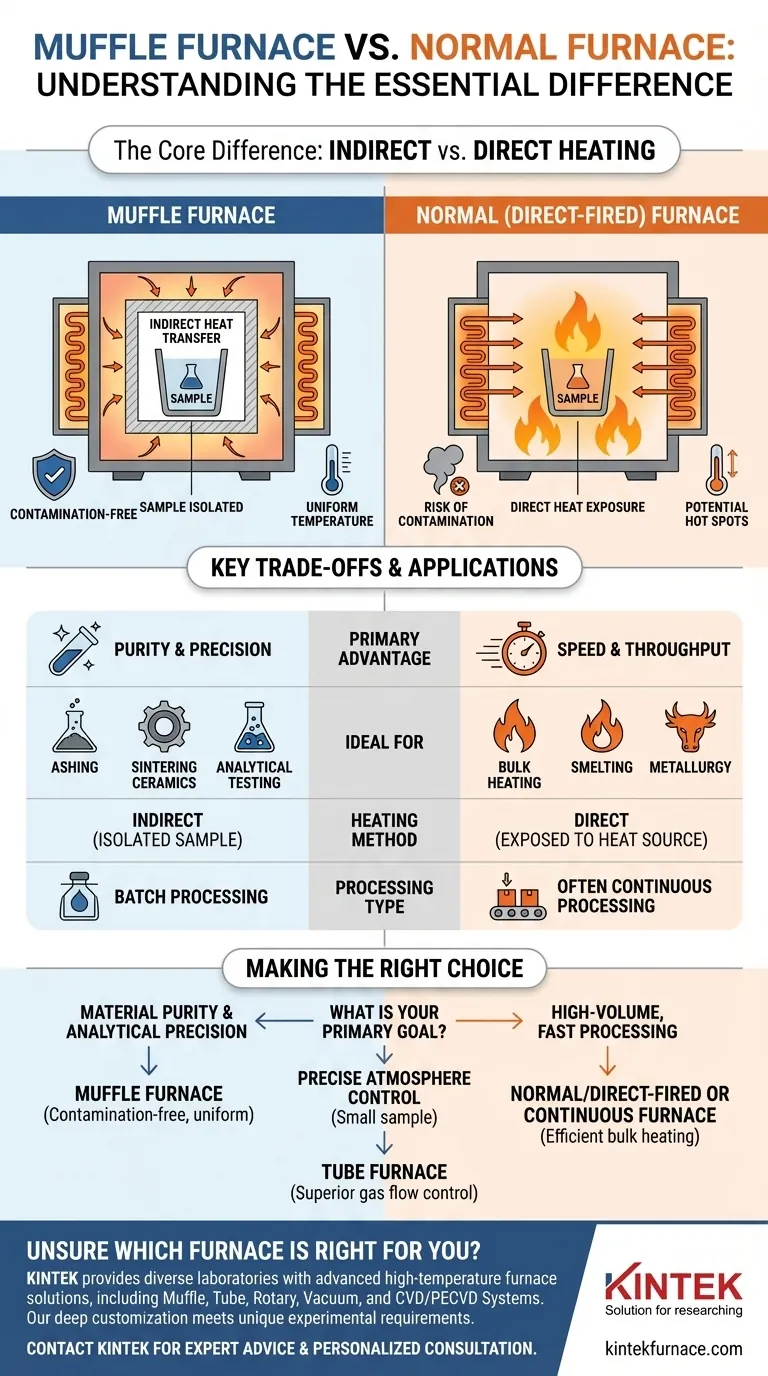

The essential difference between a muffle furnace and other furnaces lies in its method of heating. A muffle furnace uses indirect heat, isolating the material being processed from the heating elements and any combustion byproducts inside a sealed chamber. This design ensures a contamination-free environment and highly uniform temperatures, whereas most "normal" furnaces may expose the material directly to the heat source for faster, more direct energy transfer.

Choosing the right furnace is not about which is "better," but about which provides the necessary level of control. A muffle furnace prioritizes a pristine and uniformly heated environment, while other furnace types often prioritize processing speed, throughput, or direct energy transfer.

How a Muffle Furnace Achieves Isolation

The defining feature of a muffle furnace is its internal chamber, known as the "muffle." This creates a box-within-a-box design that is fundamental to its operation.

The Principle of Indirect Heating

A muffle furnace's heating elements are located outside the sealed inner chamber. These elements heat the space around the muffle, and the heat then radiates inward, warming the chamber and the sample it contains.

The sample never comes into direct contact with the heating coils or any flame, ensuring a gentle and even transfer of thermal energy.

Preventing Contamination

This indirect heating method is critical for applications where purity is paramount. By isolating the sample, the furnace prevents contamination from combustion gases or particles flaking off the heating elements.

This makes muffle furnaces indispensable for sensitive laboratory processes like ashing organic materials for analysis or sintering advanced ceramics where even trace impurities can alter the final properties.

Ensuring Temperature Uniformity

Because heat radiates from all internal surfaces of the outer chamber toward the inner muffle, it creates an exceptionally uniform temperature environment.

This eliminates hot spots that can occur in direct-fired furnaces, ensuring the entire sample is processed at the same precise temperature.

Differentiating from Other Common Furnaces

While "normal furnace" is a broad term, comparing a muffle furnace to other specific types clarifies its unique role.

Muffle vs. Tube Furnace

Both can offer high-purity, atmosphere-controlled environments. The primary difference is geometry. A muffle furnace has a large, boxy chamber ideal for processing multiple samples or bulky items.

A tube furnace has a narrow, cylindrical chamber. This design offers more precise control over gas flow and temperature gradients, but it severely limits the size and shape of the sample.

Muffle vs. Direct-Fired Furnaces

Many industrial furnaces are direct-fired, meaning a flame or combustion gas is used to heat the material directly. This method is efficient for bulk heating, smelting, or casting where speed is more important than purity.

A muffle furnace is the opposite; it sacrifices some heating speed for absolute environmental control.

Muffle vs. Continuous (Pusher) Furnaces

A muffle furnace is a batch processing tool; samples are placed inside, heated for a set time, and then removed.

In contrast, a continuous or "pusher" furnace moves material steadily through different heating zones. This is designed for high-throughput manufacturing, not the precise, stationary heating of a muffle furnace.

Understanding the Trade-offs

The isolation provided by a muffle furnace is its greatest strength, but it also comes with inherent limitations.

The Cost of Purity: Slower Heating

Indirect heating is less efficient at transferring energy than direct heating. Consequently, muffle furnaces often have slower heat-up and cool-down times compared to direct-fired models.

Limitations in Atmosphere Control

While some muffle furnaces have ports for introducing inert gas, the large chamber and door seal make it difficult to maintain a perfect vacuum or highly specific gas mixture.

For applications requiring rigorous atmosphere management, a purpose-built tube or retort furnace is often a more reliable choice.

Temperature Range

While capable of reaching high temperatures (typically up to 1100°C or 1200°C), some specialized industrial furnaces can achieve even higher temperatures required for melting refractory metals or other extreme processes.

Making the Right Choice for Your Application

Selecting the correct furnace requires matching the tool's core design to your primary objective.

- If your primary focus is material purity and analytical precision: A muffle furnace is the standard due to its contamination-free, uniform indirect heating.

- If your primary focus is high-volume, continuous processing: A continuous or pusher furnace is designed for industrial throughput and is a better fit.

- If your primary focus is precise atmosphere control over a small sample: A tube furnace offers superior control over gas flow and temperature gradients for specialized materials science.

- If your primary focus is simply bulk heating without contamination concerns: A simpler, direct-fired furnace or general-purpose oven will be more efficient and cost-effective.

By understanding that a muffle furnace is a specialized tool for purity and precision, you can confidently select the right equipment for your specific technical goal.

Summary Table:

| Feature | Muffle Furnace | "Normal" / Direct-Fired Furnace |

|---|---|---|

| Heating Method | Indirect (sample isolated in a chamber) | Direct (sample exposed to heat source) |

| Primary Advantage | Contamination-free, uniform temperature | Faster heating, higher throughput |

| Ideal For | Analytical testing (ashing), sintering ceramics, purity-critical processes | Bulk heating, smelting, processes where speed outweighs purity |

| Sample Environment | Highly controlled, isolated | Exposed to combustion gases/elements |

| Processing Type | Batch processing | Often continuous processing |

Unsure which furnace is right for your unique requirements?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements.

Let our experts help you select or customize the perfect furnace for your application. Contact us today for a personalized consultation!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing