Operating a box muffle furnace is a systematic process that begins with placing your sample inside, closing the door, and programming the controller. You then initiate the heating cycle and allow the furnace to automatically maintain the target temperature. After the process is complete, you must power down the unit and let it cool significantly before safely removing your sample.

Beyond the simple sequence of buttons, proper furnace operation is a disciplined cycle of preparation, controlled heating, and safe shutdown. Mastering this full cycle is essential for achieving accurate results, ensuring personal safety, and protecting the long-term integrity of the furnace itself.

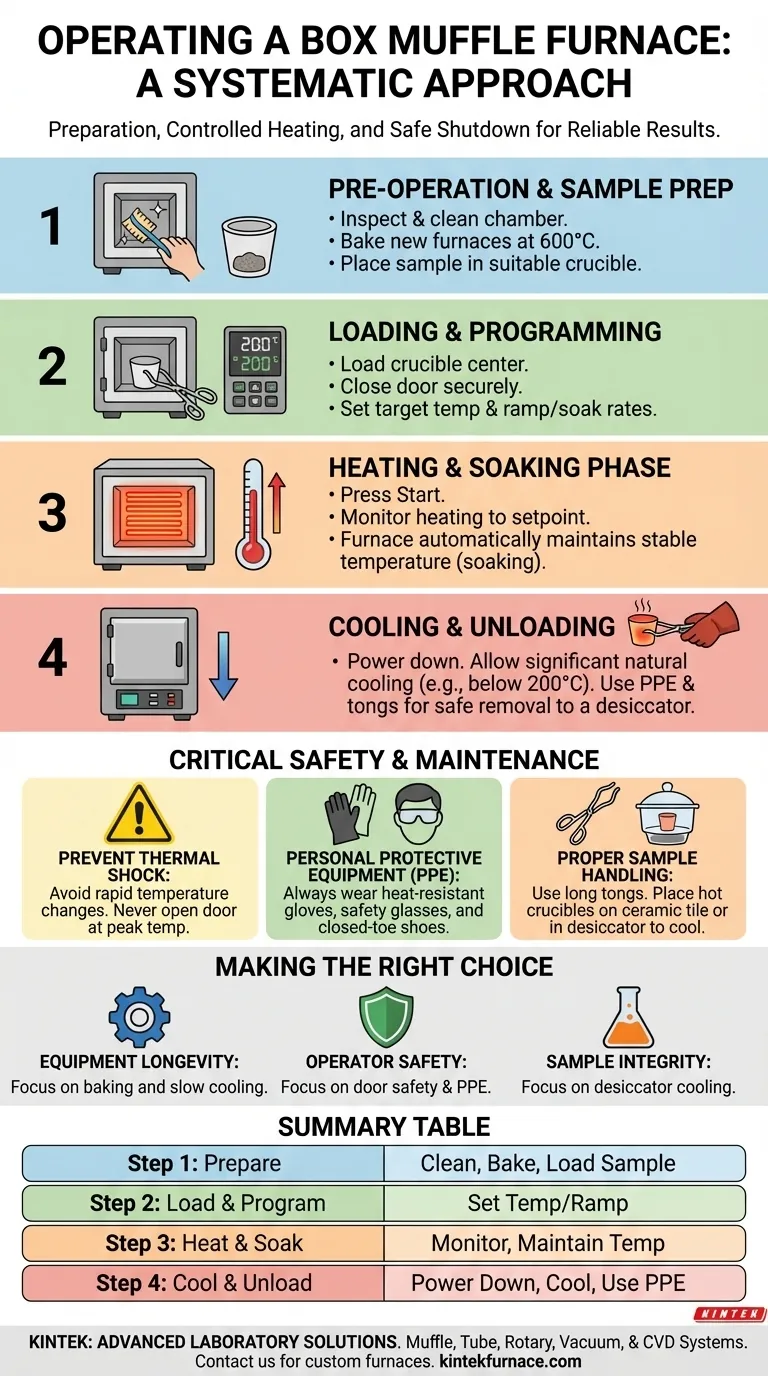

The Full Operational Cycle: From Preparation to Shutdown

A successful heating process isn't just about turning the furnace on and off. It involves a structured approach that respects the equipment and the materials being tested.

Step 1: Pre-Operation Checks and Sample Preparation

Before powering on the unit, a few preparatory steps are critical. First, inspect the furnace chamber to ensure it is clean and free of any debris from previous runs.

If you are using a new furnace or one that has been inactive for a long time, it must be baked. This involves slowly raising the temperature to around 600°C and holding it for several hours to gently drive out any moisture, which prevents cracks from forming in the refractory material.

Prepare your sample by placing it in a suitable, clean crucible or heat-resistant container.

Step 2: Loading and Programming the Furnace

Carefully place the crucible in the center of the furnace hearth. This ensures the most uniform heat exposure. Close the furnace door and ensure it is latched securely.

Turn on the main power switch. Using the temperature controller, set your desired target temperature. For more advanced processes, you may also program specific ramp rates (how fast the temperature rises) and soaking times (how long it's held at the target temperature).

Step 3: The Heating and Soaking Phase

With the program set, press the "Heating" or "Start" button to begin the cycle. The furnace will now begin to heat up toward your setpoint.

It is good practice to monitor the furnace as it approaches the target temperature. The controller will automatically stop the heating elements once the setpoint is reached and cycle them as needed to maintain a stable temperature. This "soaking" or "heat preservation" phase is often the primary purpose of the experiment.

Step 4: Cooling and Unloading

Once your process is complete, turn off the heating cycle and the main power switch. Do not open the furnace door while it is at a high temperature.

Allow the furnace to cool down naturally for a significant period. Opening the door too soon will cause thermal shock, which can damage the furnace lining and potentially crack your sample.

Once the temperature has dropped to a safe level (e.g., below 200°C), slightly open the door to allow heat to dissipate further. Using long tongs and wearing heat-resistant gloves, carefully remove the hot crucible and transfer it to a designated cooling area, such as a desiccator, to cool in a dry, controlled environment.

Critical Safety and Maintenance Considerations

A muffle furnace is a powerful tool, and overlooking safety or maintenance can lead to equipment damage or personal injury.

Preventing Thermal Shock

The single most common cause of furnace damage is thermal shock. Rapid heating or cooling creates stress in the ceramic insulation and heating elements, causing cracks.

Always bake a new furnace as instructed. Never open the door to "check on" or cool down a sample when the furnace is at peak temperature. The sudden rush of cool air is extremely damaging.

Personal Protective Equipment (PPE)

You must always use appropriate PPE. This includes heat-resistant gloves, safety glasses or a face shield, and closed-toe shoes. Heated crucibles look identical to cold ones, so always assume they are hot.

Proper Sample Handling

Use long-handled tongs to maintain a safe distance from the furnace opening and the hot crucible. Placing a hot crucible directly onto a workbench can cause damage or a fire; always use a ceramic tile, a dedicated cooling rack, or a desiccator.

Making the Right Choice for Your Goal

Your specific goal will determine which parts of the procedure you need to focus on most.

- If your primary focus is equipment longevity: Always bake a new furnace and avoid rapid temperature changes by keeping the door closed during operation and cooling.

- If your primary focus is operator safety: Never open the furnace at peak temperature and always use long tongs and appropriate PPE to handle hot crucibles.

- If your primary focus is sample integrity: Transfer heated crucibles directly to a desiccator to cool in a dry, controlled environment, preventing contamination or moisture reabsorption.

By integrating these safety and maintenance principles into the standard operating procedure, you ensure reliable results and safe, long-term use of the equipment.

Summary Table:

| Step | Description | Key Actions |

|---|---|---|

| 1. Pre-Operation | Prepare furnace and sample | Clean chamber, bake new furnace, place sample in crucible |

| 2. Loading & Programming | Set up furnace for heating | Load crucible, close door, set temperature/ramp rates |

| 3. Heating & Soaking | Execute heating cycle | Start cycle, monitor temperature, maintain setpoint |

| 4. Cooling & Unloading | Safely cool and remove sample | Power down, cool naturally, use PPE and tongs for removal |

Need a reliable high-temperature furnace for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental needs. Contact us today to enhance your laboratory's efficiency and safety with our tailored furnace solutions!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency