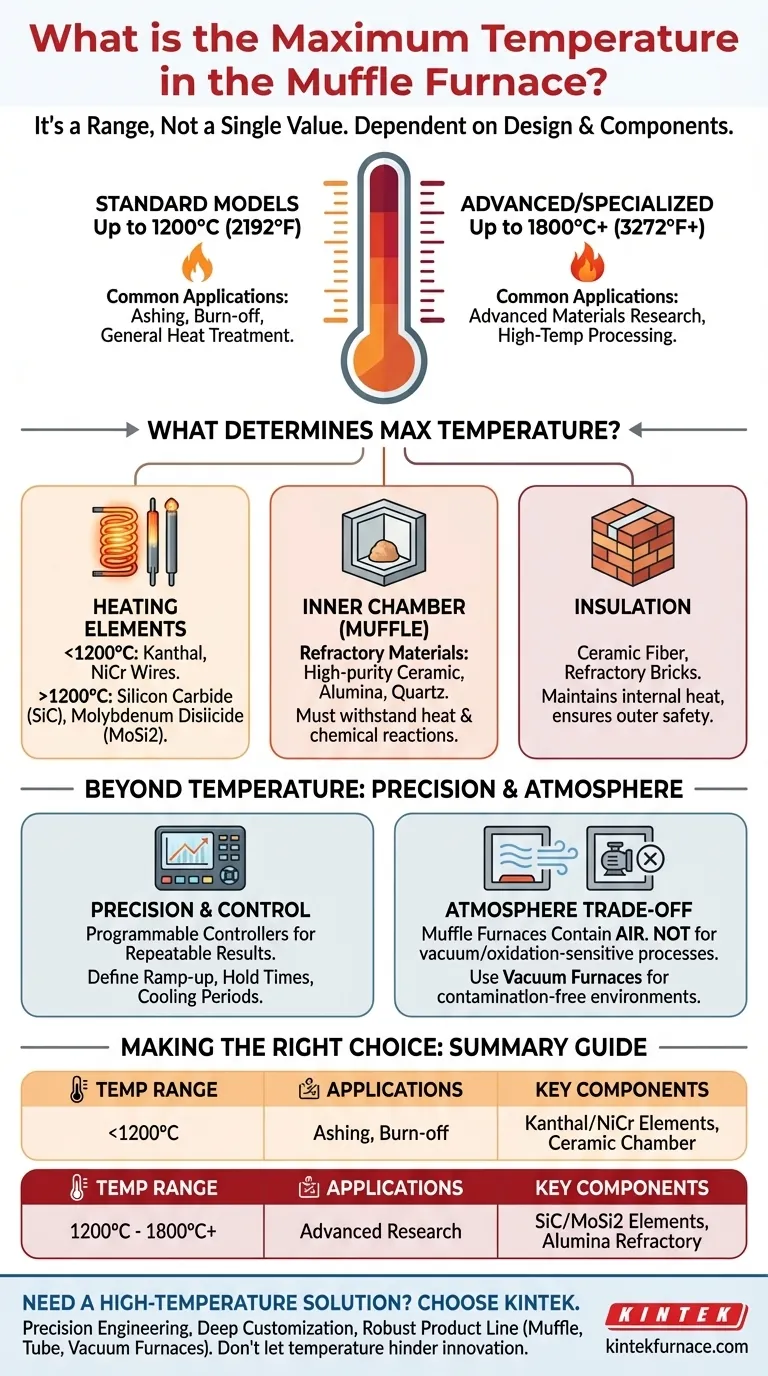

The maximum temperature of a muffle furnace varies significantly based on its design and intended application. While standard models operate up to 1200°C (2192°F), more advanced furnaces built for specialized tasks can reach or even exceed 1800°C (3272°F). The specific temperature capability is determined by the materials used in its construction, particularly the heating elements and the inner chamber.

A muffle furnace's maximum temperature is not a single value but a range defined by its components. Understanding these components is essential to selecting a furnace that can not only reach your target temperature but also provide the control and atmospheric conditions your process requires.

What Determines a Muffle Furnace's Maximum Temperature?

The ability of a furnace to safely and consistently achieve extreme heat is a direct result of its core components. The material science of the heating elements and the inner chamber dictates the unit's operational limits.

The Role of Heating Elements

Heating elements are the heart of the furnace, converting electrical energy into heat. The material they are made from is the primary factor limiting the maximum temperature.

Common materials include high-resistance wires like Kanthal or nickel-chromium for lower-temperature ranges. To achieve temperatures above 1200°C, furnaces rely on more robust elements like silicon carbide (SiC) or molybdenum disilicide (MoSi2).

The Inner Chamber (Muffle)

The muffle is the isolated inner chamber that holds the sample, protecting it from direct contact with the heating elements and combustion byproducts. This chamber must be made of a refractory material that can withstand the target temperature without degrading.

Materials like high-purity ceramic, alumina, or quartz are chosen for their thermal stability and resistance to chemical reactions at high temperatures. The integrity of the muffle is just as critical as the heating elements for reliable operation.

Insulation and Overall Construction

To maintain extreme internal temperatures efficiently and ensure the outer shell remains safe to touch, muffle furnaces are heavily insulated.

Materials like ceramic fiber or refractory bricks line the furnace body, preventing heat loss. This robust construction is essential for both performance and safety.

Precision and Control Are as Important as Temperature

Simply reaching a high temperature is not enough for scientific or industrial applications. The ability to precisely control the heating process is what makes a muffle furnace a valuable tool.

Achieving Repeatable Results

Modern muffle furnaces use sophisticated temperature controllers connected to sensors within the chamber. These systems allow for precise temperature management.

Many units feature programmable controllers that let users define entire heating cycles. This includes setting specific ramp-up rates (how fast it heats up), hold times (how long it stays at a target temperature), and cooling periods, ensuring accuracy and reproducibility.

Understanding the Key Trade-off: Atmosphere vs. Temperature

While excellent for heating in air, the fundamental design of a muffle furnace presents a critical limitation that users must understand.

Muffle Furnaces Are Not Vacuum Furnaces

The muffle isolates the sample from combustion gases, but it does not create a vacuum. The chamber contains air.

For processes that are sensitive to oxygen or other atmospheric gases, such as sintering certain metals or advanced material synthesis, a muffle furnace is unsuitable. These applications require a vacuum furnace, which is specifically designed to eliminate air and create a contamination-free environment.

Making the Right Choice for Your Application

Selecting the correct furnace requires you to look past the maximum temperature and consider the specific demands of your process.

- If your primary focus is ashing, burn-off, or general heat treatment below 1200°C: A standard muffle furnace with Kanthal-type heating elements is a reliable and cost-effective choice.

- If your primary focus is advanced materials research or processes requiring up to 1800°C: You must invest in a specialized, high-temperature furnace equipped with SiC or MoSi2 elements and an appropriate refractory chamber.

- If your primary focus is contamination-free processing in an inert or vacuum environment: A muffle furnace is the wrong tool; you must use a vacuum furnace designed for atmospheric control.

Ultimately, matching the furnace's capabilities to your specific scientific or industrial goal is the key to achieving successful and repeatable results.

Summary Table:

| Temperature Range | Common Applications | Key Components |

|---|---|---|

| Up to 1200°C | Ashing, burn-off, general heat treatment | Kanthal/NiCr elements, ceramic chamber |

| 1200°C to 1800°C+ | Advanced materials research, high-temp processing | SiC/MoSi2 elements, alumina refractory |

Need a High-Temperature Solution Tailored to Your Exact Requirements?

At KINTEK, we understand that achieving precise thermal processing is critical to your research and production success. Our advanced high-temperature furnaces are engineered to deliver not just extreme heat, but also the precise control and reliability your work demands.

Why Choose KINTEK for Your High-Temperature Needs?

- Precision Engineering: Leveraging our exceptional in-house R&D and manufacturing capabilities, we build furnaces that provide accurate temperature control and uniform heating for repeatable results.

- Deep Customization: Whether you need a standard muffle furnace or a specialized system reaching 1800°C+, we work with you to tailor the heating elements, chamber materials, and control systems to your unique experimental requirements.

- Robust Product Line: Our portfolio includes Muffle Furnaces, Tube Furnaces, and sophisticated Vacuum & Atmosphere Furnaces, ensuring we have the right tool for your specific application.

Don't let temperature limitations hinder your innovation.

Contact our thermal experts today to discuss your project needs. Let us help you select or custom-build the perfect furnace solution to achieve your goals.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production