At its core, a muffle furnace's sealed design enhances safety by creating a physical barrier that isolates three critical components from each other: the operator, the material being heated (the sample), and the heating source. This separation is the fundamental principle that prevents burns, contains hazardous fumes, and ensures a stable, predictable process, which is essential for working safely with extreme temperatures.

The sealed muffle chamber is not merely a container; it is a controlled environment. Its primary safety function is to contain heat, hazardous chemical reactions, and process byproducts, protecting the user, the equipment, and the integrity of the sample itself.

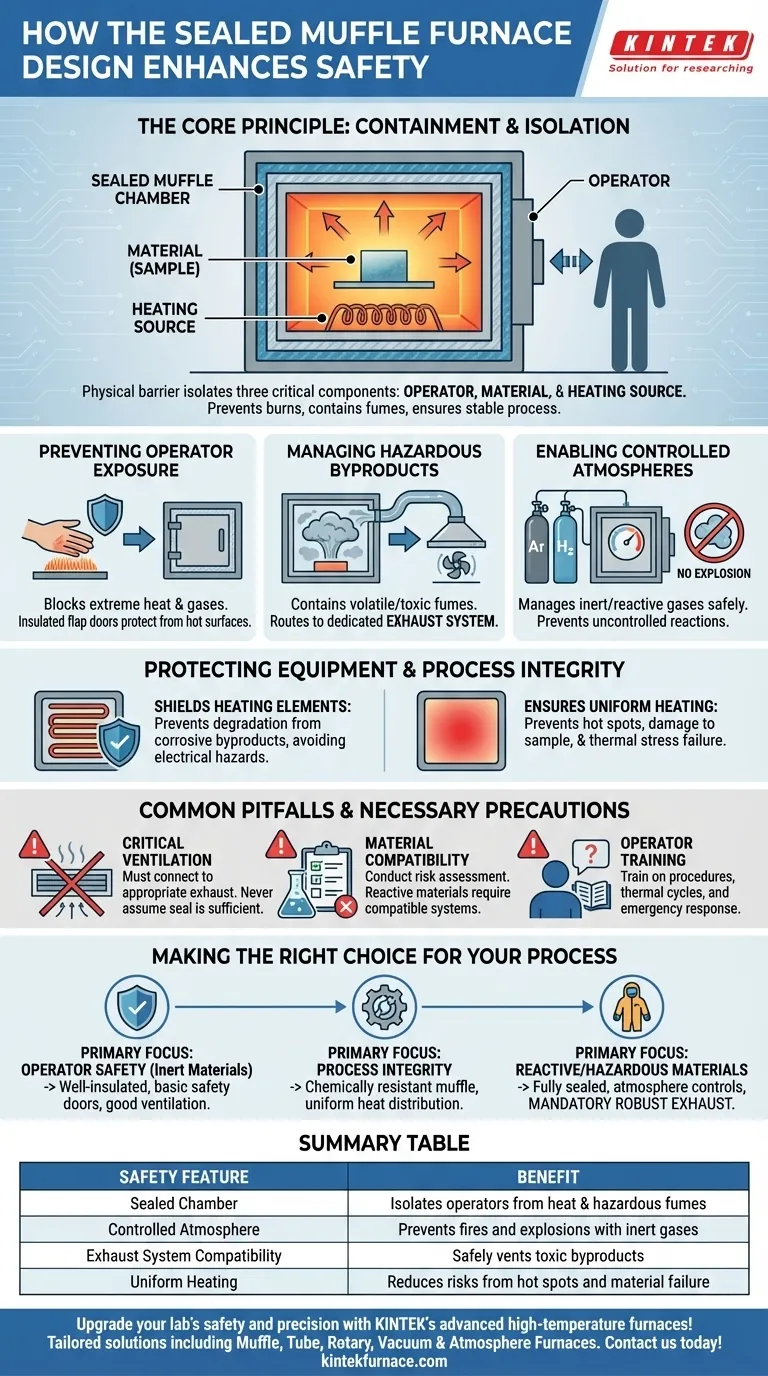

The Core Principle: Containment and Isolation

The primary safety advantage of a muffle furnace stems from its design, where an inner chamber—the "muffle"—is sealed off from both the external environment and the heating elements. This creates multiple layers of protection.

Preventing Direct Operator Exposure

The most immediate risk in high-temperature work is thermal injury. The sealed chamber, combined with robust insulation, contains extreme heat within the furnace.

Features like insulated flap doors or adjustable air inlets further protect operators from hot surfaces and any hot gases that might escape when the furnace is opened.

Managing Hazardous Byproducts

Heating materials can release volatile, corrosive, or toxic gases. A sealed design is critical for containing these byproducts.

This containment allows the fumes to be managed safely, typically by routing them into a dedicated exhaust system or fume hood. This prevents the release of harmful substances into the lab or workspace.

Enabling Controlled Atmospheres

Many advanced processes require a specific atmosphere, such as an inert gas like argon or a reactive one like hydrogen. A sealed chamber is the only way to safely manage these conditions.

Introducing reactive gases into an unsealed environment with high heat and oxygen would create a significant risk of fire or explosion. The sealed design prevents uncontrolled reactions by isolating the process from ambient air.

How Isolation Protects Equipment and Process Integrity

Safety extends beyond just protecting personnel. A stable and predictable system is inherently safer, and the sealed design contributes directly to the furnace's reliability and the integrity of the work being done.

Shielding the Heating Elements

The muffle acts as a protective barrier for the heating elements. Process byproducts, such as corrosive fumes or powders, can degrade and destroy heating elements over time.

Protecting these elements prevents equipment failure, which could otherwise lead to electrical hazards or unexpected temperature fluctuations that compromise safety.

Ensuring Uniform and Predictable Heating

The sealed muffle is engineered from materials like alumina or refractory ceramics to ensure even heat distribution. This prevents hot spots that could damage the sample or the chamber itself.

By preventing direct contact with flames or heating coils, the furnace provides uniform heating, which is critical for process control and avoids the thermal stresses that can lead to material failure.

Common Pitfalls and Necessary Precautions

A sealed design is a powerful safety feature, but it is not infallible. Its effectiveness depends on proper use and supplementary systems.

The Critical Need for Ventilation

Containing gases is only half the solution. If these gases are not vented, pressure can build inside the chamber, creating a risk of rupture or a sudden release of hazardous fumes when the door is opened.

A sealed furnace used for processes that generate fumes must be connected to an appropriate exhaust system. Never assume the seal alone is sufficient.

Material Compatibility and Risk Assessment

Not all materials can be safely heated in a standard muffle furnace. Some substances may release highly reactive or explosive compounds at high temperatures.

Always conduct a thorough risk assessment of your materials. Ensure the furnace's construction and ventilation systems are compatible with the specific byproducts your process will generate.

Overlooking Operator Training

Safety features reduce risk, but they do not eliminate it. Operators must be trained on the specific procedures for loading, unloading, and programming the furnace.

Understanding how to manage thermal cycles and how to respond in an emergency is just as important as the furnace's built-in safety mechanisms.

Making the Right Choice for Your Process

The level of safety and control you need depends entirely on your application. Use your primary goal to guide your evaluation of a furnace's sealed design.

- If your primary focus is operator safety with inert materials: A well-insulated furnace with basic door safety mechanisms and good ventilation is sufficient.

- If your primary focus is process integrity and repeatability: Prioritize a furnace with a chemically resistant muffle material that ensures uniform heat distribution.

- If your primary focus is working with reactive or hazardous materials: A fully sealed chamber with integrated atmosphere controls and a mandatory, robust exhaust system is non-negotiable.

Ultimately, the sealed design transforms the muffle furnace from a simple oven into a precise and secure instrument for high-temperature applications.

Summary Table:

| Safety Feature | Benefit |

|---|---|

| Sealed Chamber | Isolates operators from heat and hazardous fumes |

| Controlled Atmosphere | Prevents fires and explosions with inert gases |

| Exhaust System Compatibility | Safely vents toxic byproducts |

| Uniform Heating | Reduces risks from hot spots and material failure |

Upgrade your lab's safety and precision with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met for enhanced operator protection and process integrity. Contact us today to discuss how we can support your high-temperature applications!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?