The primary advantages of a muffle furnace are its ability to achieve high temperatures with exceptional uniformity and precision while keeping the sample isolated from contamination. This unique combination makes it an indispensable tool for analytical testing, materials research, and small-scale heat-treating processes where sample purity and repeatable results are critical.

A muffle furnace is not just a high-temperature oven; its core value lies in providing a chemically isolated and thermally uniform environment. This control ensures the integrity of your sample and the reliability of your thermal process.

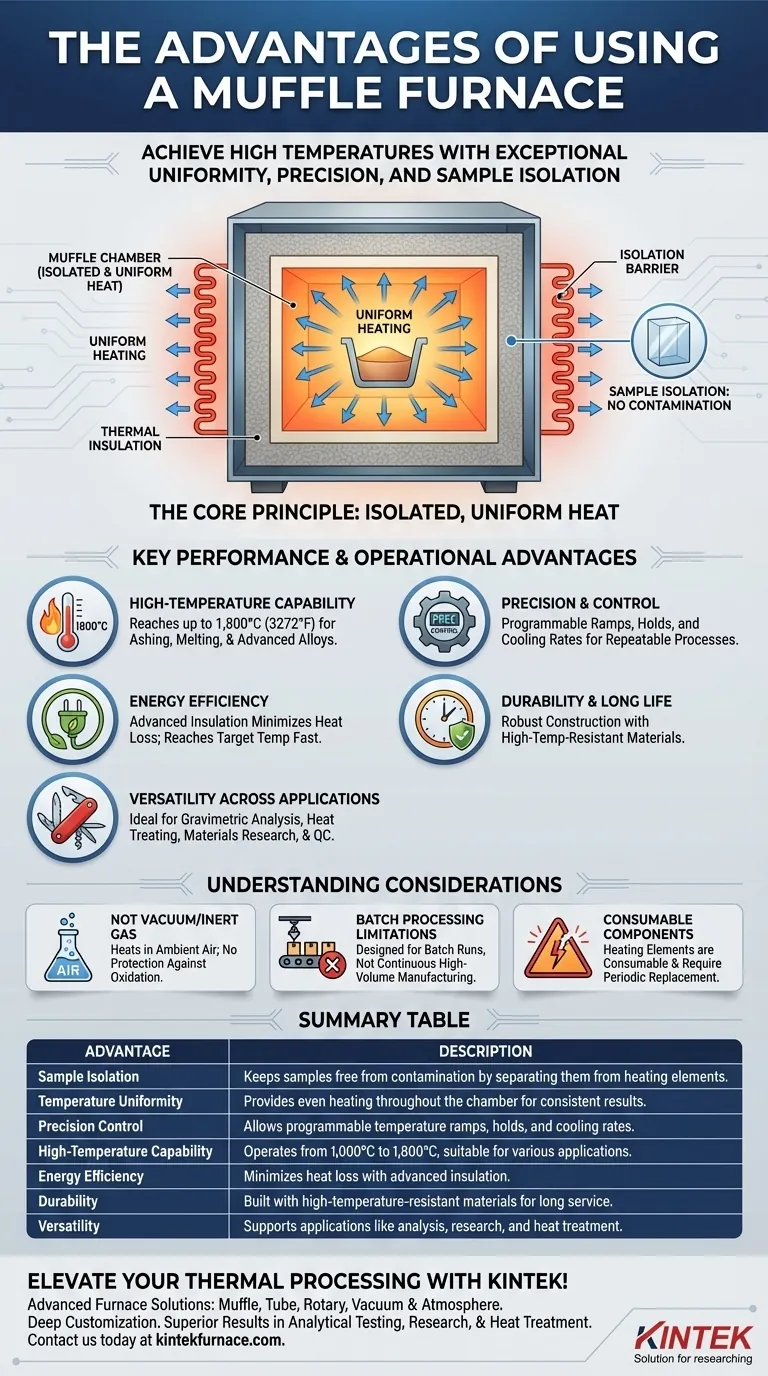

The Core Principle: Isolated, Uniform Heat

The name "muffle furnace" itself reveals its most important feature. Understanding this principle is key to seeing its value beyond just high heat.

What "Muffle" Means for Your Sample

The term "muffle" refers to the inner chamber that encloses the material being heated. This chamber separates the sample from the heating elements and any byproducts of combustion (in fuel-fired furnaces).

This sample isolation is the furnace's defining advantage. It prevents contamination, ensuring that the changes observed in the sample are strictly due to the application of heat, not a chemical reaction with outside elements.

Achieving True Temperature Uniformity

A key design goal of a muffle furnace is to deliver temperature uniformity. The insulated chamber is engineered to radiate heat evenly from all sides.

This eliminates hot and cold spots within the processing area. For processes like annealing metals or sintering ceramics, uniform heating is non-negotiable for achieving consistent material properties.

Precision and Control

Modern muffle furnaces are equipped with digital controllers that allow for precise temperature management. Users can program specific temperature ramps, holds (dwell times), and cooling rates.

This level of control ensures that thermal processes are repeatable, which is essential for quality control protocols and scientific experiments.

Key Performance and Operational Advantages

Beyond its core principle, a muffle furnace offers several practical benefits that make it a go-to instrument in laboratories and workshops.

High-Temperature Capability

Muffle furnaces are designed to operate at very high temperatures, often ranging from 1,000°C to 1,800°C (1832°F to 3272°F), depending on the model and heating elements. This capability is essential for applications like ashing, melting glass, or creating advanced alloys.

Energy Efficiency

Compared to open-flame forges or less-insulated ovens, muffle furnaces are highly energy-efficient. Their advanced insulation materials minimize heat loss, allowing them to reach and maintain target temperatures with less energy consumption. Many can reach maximum temperature in about an hour.

Durability and Long Service Life

These furnaces are built from durable, high-temperature-resistant materials. Their robust construction ensures they can withstand the stress of repeated, extreme thermal cycles, leading to a long and reliable service life.

Versatility Across Applications

The controlled environment of a muffle furnace makes it suitable for a wide range of tasks:

- Gravimetric Analysis: Determining the non-combustible "ash" content of a sample.

- Heat Treating: Hardening, annealing, or tempering small metal parts.

- Materials Research: Developing and testing new alloys, ceramics, and composites.

- Quality Control: Verifying the properties of materials through controlled heating.

Understanding the Trade-offs and Considerations

While highly effective, a muffle furnace is a specialized tool with specific limitations. Being aware of them is crucial for proper selection.

It's Not a Vacuum or Inert Gas Furnace

A standard muffle furnace heats samples in the presence of ambient air. While it isolates from combustion contaminants, it does not protect against oxidation. For processes requiring an inert atmosphere (like argon or nitrogen) or a vacuum, a specialized furnace is necessary.

Batch Processing Limitations

Muffle furnaces are designed for batch processing, not continuous, high-volume manufacturing. The size of the chamber limits the throughput, making them ideal for labs, R&D, and small-scale production runs.

Consumable Components

The heating elements that generate the extreme temperatures are consumable parts. While they are designed for longevity, they will eventually degrade and require replacement. This should be factored into the total cost of ownership.

Making the Right Choice for Your Goal

To determine if a muffle furnace is the correct tool, match its core strengths to your primary objective.

- If your primary focus is analytical testing (e.g., ashing): The furnace's sample isolation and precise temperature control are its most critical advantages, ensuring accurate and repeatable results.

- If your primary focus is materials science or R&D: The combination of high-temperature capability, versatility, and uniform heating allows you to test and develop a wide range of materials under controlled conditions.

- If your primary focus is small-scale heat treatment: The precise control over temperature ramps and holds ensures you can achieve consistent metallurgical properties for quality control.

Ultimately, choosing a muffle furnace is a decision to prioritize control, purity, and repeatability in your thermal processing.

Summary Table:

| Advantage | Description |

|---|---|

| Sample Isolation | Keeps samples free from contamination by separating them from heating elements and combustion byproducts. |

| Temperature Uniformity | Provides even heating throughout the chamber, eliminating hot and cold spots for consistent results. |

| Precision Control | Allows programmable temperature ramps, holds, and cooling rates for repeatable processes. |

| High-Temperature Capability | Operates from 1,000°C to 1,800°C, suitable for ashing, melting, and heat treating. |

| Energy Efficiency | Minimizes heat loss with advanced insulation, reducing energy consumption. |

| Durability | Built with high-temperature-resistant materials for long service life in demanding conditions. |

| Versatility | Supports applications like gravimetric analysis, materials research, and small-scale heat treatment. |

Elevate your laboratory's thermal processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering contamination-free, uniform heating for superior results in analytical testing, materials research, and small-scale heat treatment. Ready to optimize your processes? Contact us today to discuss how our tailored solutions can benefit your work!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO