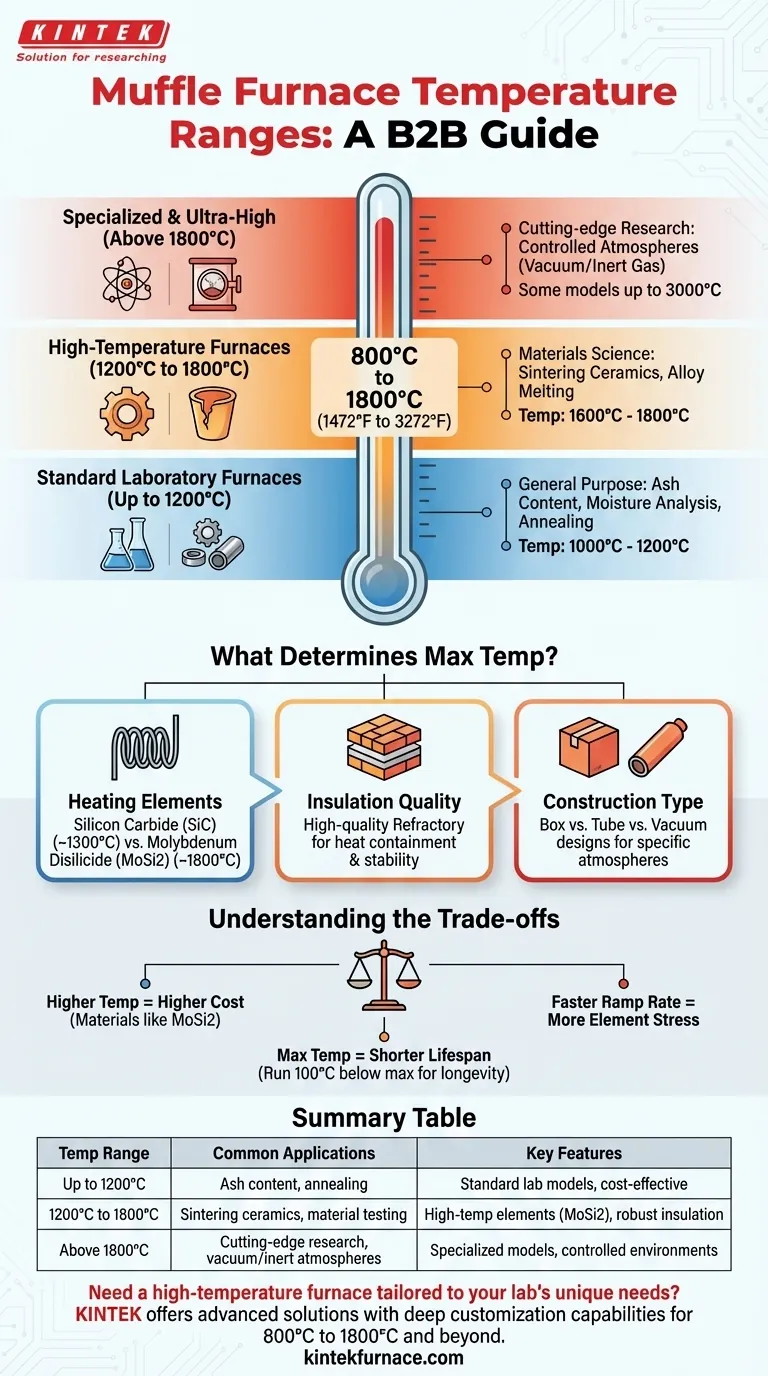

In short, a muffle furnace's operating temperature typically ranges from 800°C to 1800°C (1472°F to 3272°F). However, this wide range is segmented by furnace type. Standard laboratory models usually operate up to 1200°C, while specialized high-temperature units are required for processes demanding 1600°C to 1800°C.

The maximum temperature of a muffle furnace is not a single specification, but a defining characteristic that separates the equipment into distinct tiers. Choosing the right furnace means matching your specific application's temperature needs to the correct tier to ensure both performance and longevity.

Understanding the Tiers of Muffle Furnace Temperatures

The operating temperature is the most critical factor in classifying a muffle furnace. Each tier is designed with different materials and for different purposes.

Standard Laboratory Furnaces (Up to 1200°C)

Most general-purpose muffle furnaces fall into this category, with maximum temperatures typically between 1000°C and 1200°C.

These are the workhorses for routine applications like determining ash content, moisture analysis, general heat treating, and annealing common metals.

High-Temperature Furnaces (1200°C to 1800°C)

These furnaces are built for more demanding applications in materials science, metallurgy, and advanced ceramics.

Reaching temperatures of 1600°C to 1800°C is necessary for processes like sintering high-purity ceramics, melting certain alloys, or testing materials under extreme thermal stress.

Specialized and Ultra-High Temperature Models (Above 1800°C)

A small subset of furnaces can exceed 1800°C, with some highly specialized models reaching up to 3000°C.

These are typically reserved for cutting-edge research, often incorporating controlled atmospheres like vacuum or inert gas to prevent oxidation during sensitive high-temperature processes.

What Determines a Furnace's Maximum Temperature?

A furnace's temperature capability is not arbitrary; it is a direct result of its engineering and the materials used in its construction.

The Role of Heating Elements

The heating element is the heart of the furnace and the primary determinant of its temperature range.

Furnaces operating up to ~1300°C often use silicon carbide (SiC) rods. For temperatures above that, up to ~1800°C, more robust molybdenum disilicide (MoSi2) heating elements are required.

The Importance of Insulation

High-quality refractory insulation is critical for containing extreme heat. The better the insulation, the more efficiently the furnace can reach and maintain its target temperature, improving uniformity and stability.

Overall Furnace Construction

The physical design also plays a part. A box furnace is a general-purpose design, while a tube furnace allows for more controlled atmospheres. Vacuum furnaces are complex systems designed specifically for high-temperature work in a non-oxidizing environment.

Understanding the Trade-offs

Selecting a furnace involves more than just picking the highest number. You must balance performance, cost, and longevity.

Higher Temperature vs. Higher Cost

There is a direct correlation between maximum temperature and price. The materials needed for high-temperature operation—such as MoSi2 elements and high-purity alumina insulation—are significantly more expensive.

Operating Temperature vs. Equipment Lifespan

Constantly running a furnace at its absolute maximum temperature will drastically shorten the life of its heating elements and insulation. This is the most common and costly mistake users make.

A furnace operated consistently below its rated maximum will last significantly longer and require less maintenance.

Temperature Rise Time (Ramp Rate)

The "rise time," or how quickly the furnace reaches its setpoint, is another key performance metric. Faster ramp rates can improve throughput but may put additional stress on the heating elements.

Making the Right Choice for Your Application

Use your primary goal to guide your selection.

- If your primary focus is general lab work like ashing, drying, or basic heat treating: A standard furnace with a maximum temperature of 1100°C to 1200°C is the most practical and cost-effective choice.

- If your primary focus is materials science, advanced ceramics, or high-temperature alloy testing: You must invest in a high-temperature furnace capable of reaching 1600°C to 1800°C.

- If your primary focus is maximizing equipment lifespan and reliability: Always choose a furnace with a maximum temperature rating at least 100°C higher than your highest typical operating temperature.

Understanding that temperature dictates furnace design empowers you to select a tool that is not only capable but also reliable and cost-effective for your specific needs.

Summary Table:

| Temperature Range | Common Applications | Key Features |

|---|---|---|

| Up to 1200°C | Ash content, moisture analysis, annealing | Standard lab models, cost-effective |

| 1200°C to 1800°C | Sintering ceramics, alloy melting, material testing | High-temp elements like MoSi2, robust insulation |

| Above 1800°C | Cutting-edge research, vacuum/inert atmospheres | Specialized models, controlled environments |

Need a high-temperature furnace tailored to your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise performance for applications from 800°C to 1800°C and beyond. Contact us today to enhance your efficiency and reliability!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation