In the paint industry, a muffle furnace is not used for mass production but serves as a critical analytical instrument in laboratory settings. Its primary functions are for high-temperature testing, such as determining the inorganic content of a paint sample through ashing and evaluating the performance of specialized coatings under extreme thermal stress.

A muffle furnace's value is not in drying painted products at scale, but in providing a highly controlled, high-temperature environment for the quality control and research & development of paint formulations and raw materials.

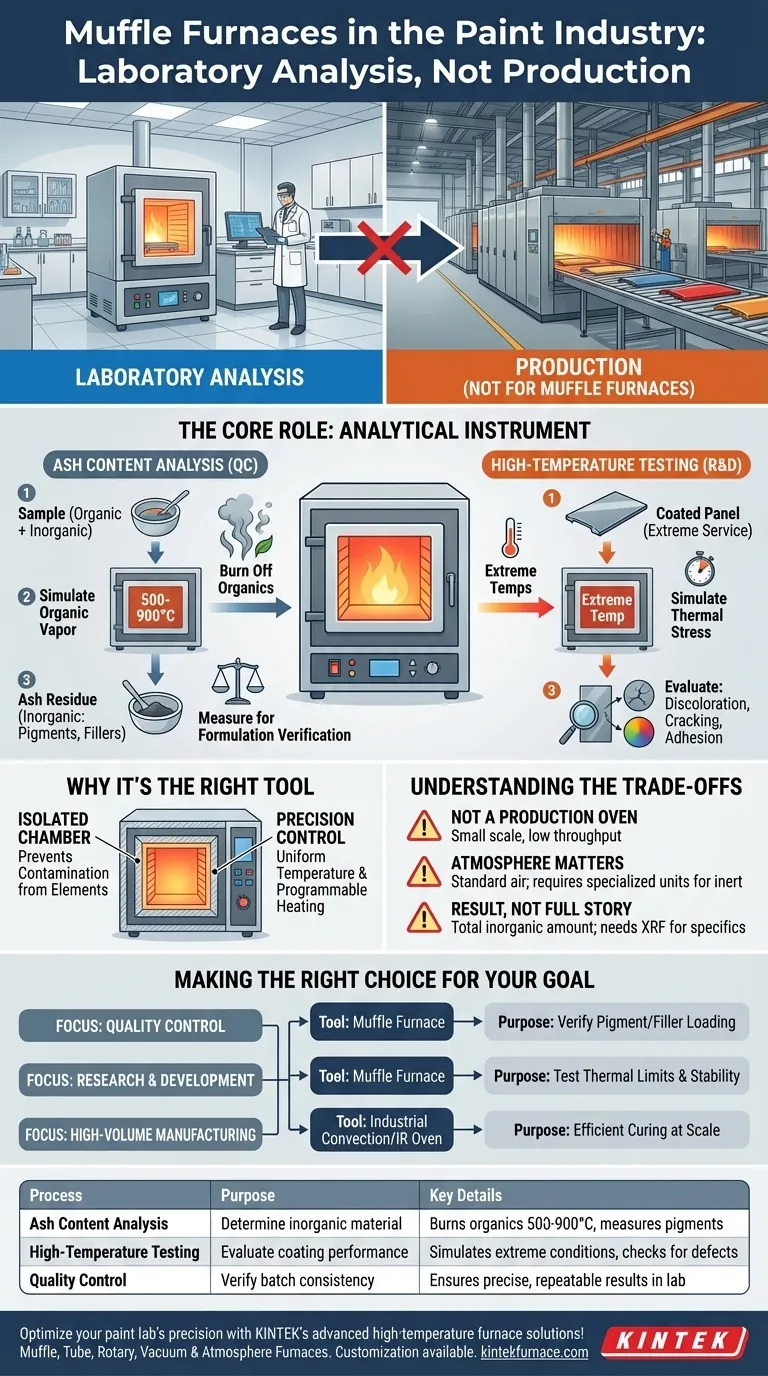

The Core Role: Laboratory Analysis, Not Production

A common misconception is that muffle furnaces are used to dry or cure painted goods on a production line. Instead, their role is almost exclusively confined to the lab, where precision and repeatability are paramount.

Determining Ash Content

The most frequent use of a muffle furnace in the paint industry is for ash content analysis. This is a fundamental quality control (QC) test.

The process involves placing a small, precisely weighed paint sample into the furnace and heating it to a very high temperature (e.g., 500-900°C). This completely burns off all organic components, including binders, resins, and solvents.

What remains is the ash, which consists of the inorganic materials: pigments (like titanium dioxide), extenders, and fillers (like calcium carbonate). Weighing this residue allows chemists to verify that the formulation matches its specification, ensuring batch-to-batch consistency.

High-Temperature Performance Testing

For developing specialized coatings, a muffle furnace is essential for simulating extreme service conditions.

This includes drying and curing tests for high-performance enamels or ceramic-based coatings designed to withstand intense heat. The furnace allows formulators to observe how a coating behaves under thermal stress, checking for discoloration, cracking, or loss of adhesion.

Why a Muffle Furnace is the Right Tool

The unique design of a muffle furnace is what makes it ideal for these analytical tasks. The "muffle" is an insulated chamber that isolates the sample from direct contact with the heating elements.

Preventing Contamination

Isolation ensures that combustion byproducts from the heating elements (in fuel-fired models) or flaking from the elements themselves do not contaminate the sample. This is critical for obtaining an accurate ash content measurement.

Ensuring Thermal Uniformity

High-quality insulation and modern controllers provide extremely uniform and precisely controlled temperatures. This allows for programmable heating ramps and soaking periods, which are essential for repeatable scientific testing. The controlled cooling capabilities are also vital for analyzing how a coating responds to thermal shock.

Understanding the Trade-offs

While invaluable, a muffle furnace is a specialized tool with clear limitations that define its proper use case.

It Is Not a Production Oven

Muffle furnaces are typically small and are not designed for the throughput required in a manufacturing setting. For curing paints on a production line, manufacturers use large industrial convection or infrared (IR) ovens that are engineered for scale and efficiency.

Atmosphere is a Key Factor

A standard muffle furnace operates with an air atmosphere. During ashing, this oxygen-rich environment is necessary for complete combustion. However, for certain high-temperature tests where oxidation must be prevented, a specialized furnace with controlled or inert atmosphere capabilities (e.g., using nitrogen or argon) is required.

It Provides a Result, Not the Full Story

Ash content analysis tells you the total amount of inorganic material, but it doesn't identify the specific components. For a more detailed chemical breakdown, analysts must use supplementary techniques like X-ray Fluorescence (XRF) or other advanced spectroscopic methods.

Making the Right Choice for Your Goal

To leverage a muffle furnace effectively, you must align the tool with your objective.

- If your primary focus is Quality Control: A muffle furnace is the industry-standard tool for verifying the pigment and filler loading of your paint via ash content analysis.

- If your primary focus is Research & Development: Use the furnace to test the thermal limits and stability of new high-temperature coatings or to analyze the composition of raw materials.

- If your primary focus is High-Volume Manufacturing: A muffle furnace is not the right tool; you need to specify a large-scale industrial oven tailored to your production line's speed and curing requirements.

Ultimately, understanding a muffle furnace's role as an analytical instrument empowers you to ensure paint quality and innovate with confidence.

Summary Table:

| Process | Purpose | Key Details |

|---|---|---|

| Ash Content Analysis | Determine inorganic material in paint | Burns off organics at 500-900°C, measures pigments and fillers |

| High-Temperature Testing | Evaluate coating performance under heat | Simulates extreme conditions, checks for discoloration or cracking |

| Quality Control | Verify batch consistency and formulation | Ensures precise, repeatable results in lab settings |

Optimize your paint lab's precision with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for quality control and R&D. Contact us today to discuss how our solutions can enhance your analytical processes and drive innovation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control