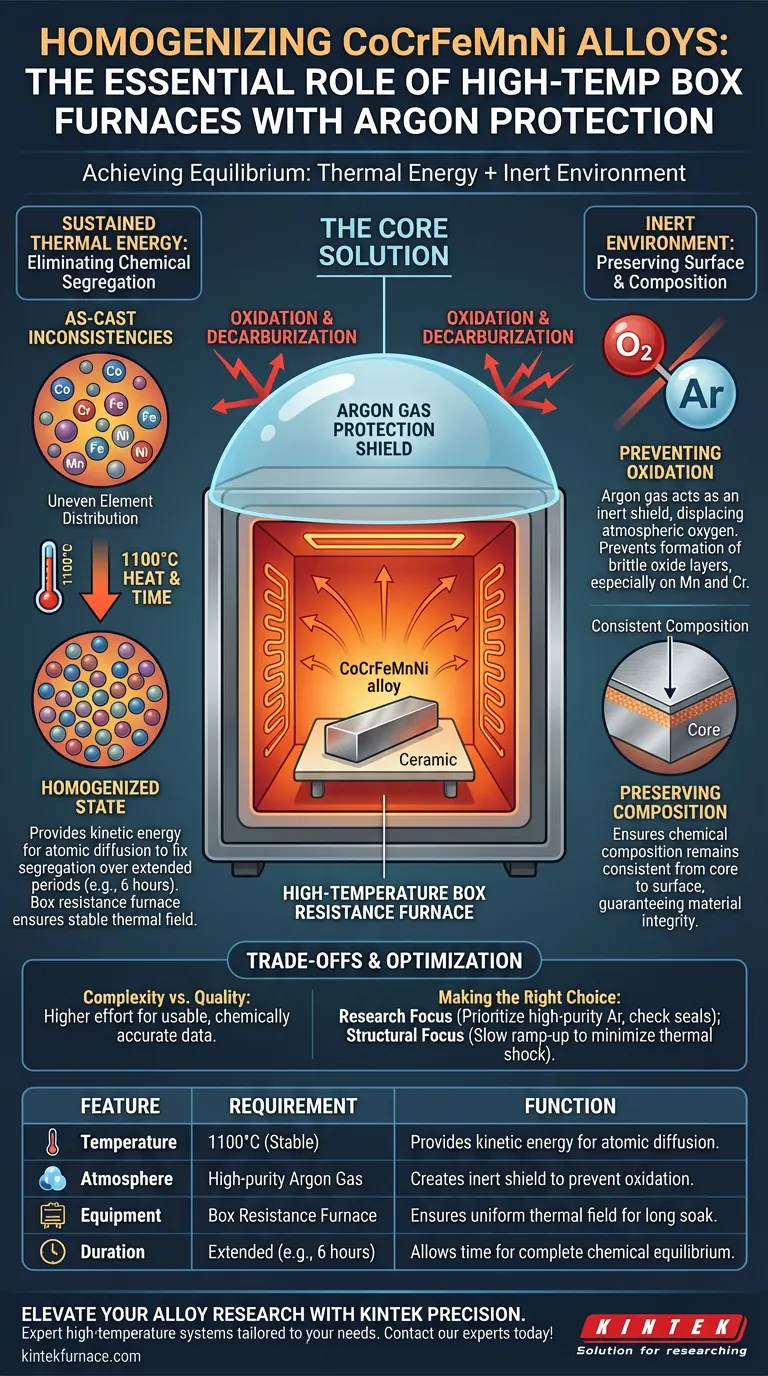

A high-temperature box resistance furnace with argon gas protection is essential for homogenizing CoCrFeMnNi alloys because it simultaneously provides the sustained thermal energy required to eliminate chemical segregation and the inert environment needed to preserve surface integrity. Specifically, the furnace maintains a stable 1100°C temperature field to drive atomic diffusion, while the argon atmosphere prevents severe oxidation and decarburization that would otherwise compromise the alloy's composition during the extended heat treatment.

The core challenge of homogenization is that the high temperatures required to mix atoms also make the metal highly reactive to air. The furnace setup solves this by providing the necessary heat while strictly isolating the material from oxygen to prevent surface degradation.

The Core Objective: Eliminating Chemical Segregation

Overcoming As-Cast Inconsistencies

When CoCrFeMnNi alloys are cast, they naturally develop chemical segregation, where elements are distributed unevenly throughout the structure. To correct this, the material must undergo a homogenization process that forces atoms to migrate and mix evenly. This creates a uniform "equilibrium" state that is critical for the material's mechanical performance.

The Role of Thermal Stability

Achieving this uniformity requires a precise, high-energy environment, typically around 1100°C. A box resistance furnace is selected because it provides a highly stable thermal field that can be maintained for extended periods (e.g., six hours). This sustained heat input provides the kinetic energy necessary for solid-state diffusion, effectively erasing the chemical gradients formed during casting.

The Critical Necessity of Argon Protection

Preventing Surface Oxidation

At 1100°C, the metallic elements in the alloy—particularly Manganese and Chromium—become extremely reactive to oxygen. Without protection, the surface of the alloy would suffer severe oxidation, leading to the formation of brittle oxide layers. Argon gas acts as an inert shield, displacing atmospheric oxygen and preventing these destructive chemical reactions from occurring.

Preserving Compositional Precision

Beyond simple oxidation, exposure to air at these temperatures can lead to decarburization or the selective loss of volatile elements from the surface. This alters the local chemistry of the specimen, creating a "skin" that behaves differently than the core. Argon protection ensures that the chemical composition remains consistent from the core to the surface, guaranteeing material integrity.

Understanding the Trade-offs

Equipment Complexity vs. Sample Quality

While adding an argon atmosphere increases the complexity and operational cost of the heat treatment, it is non-negotiable for high-performance alloys. Omitting the gas protection to save costs will result in wasted samples due to heavy scaling and surface degradation. The trade-off is higher upfront effort for the guarantee of usable, chemically accurate data.

Batch Processing Limitations

Box resistance furnaces are typically designed for batch processing rather than continuous flow. This allows for excellent control over specific temperature profiles and atmosphere purity for research or high-value parts. However, this design may be a bottleneck for high-volume manufacturing compared to continuous conveyor furnaces.

Making the Right Choice for Your Goal

To optimize your homogenization process, align your equipment settings with your specific objectives:

- If your primary focus is research accuracy: Prioritize high-purity argon flow and confirm the furnace's seal integrity to prevent even micro-oxidation that could skew surface analysis.

- If your primary focus is structural integrity: Ensure the furnace is programmed for a slow, controlled ramp-up to 1100°C to minimize thermal shock before the soak period begins.

Precision in the thermal environment is the only path to a truly homogenized, high-performance alloy.

Summary Table:

| Feature | Requirement for CoCrFeMnNi | Function in Homogenization |

|---|---|---|

| Temperature | 1100°C (Stable) | Provides kinetic energy for atomic diffusion to fix segregation. |

| Atmosphere | High-purity Argon Gas | Creates an inert shield to prevent surface oxidation & scaling. |

| Equipment | Box Resistance Furnace | Ensures a uniform thermal field during long soak periods. |

| Duration | Extended (e.g., 6 hours) | Allows sufficient time for complete chemical equilibrium. |

Elevate Your Alloy Research with KINTEK Precision

Don't let oxidation compromise your high-performance materials. Backed by expert R&D and manufacturing, KINTEK offers high-temperature Box, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of material homogenization. Whether you need precise atmosphere control or customizable thermal profiles for CoCrFeMnNi alloys, our lab solutions are tailored to your unique research needs.

Ready to achieve superior material integrity? Contact our experts today to find the perfect furnace solution for your laboratory.

Visual Guide

References

- Tae Hyeong Kim, Jae Wung Bae. Suppressed Plastic Anisotropy via Sigma-Phase Precipitation in CoCrFeMnNi High-Entropy Alloys. DOI: 10.3390/ma17061265

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How do high-precision heating furnaces ensure quality during high-temperature capillary imprinting? | KINTEK

- What is the primary role of high-precision muffle furnaces in the sintering process of high-entropy alloys?

- What role does a muffle furnace play in the curing process of GaN and TiO2? Optimize Your Photoanode Sintering

- What is the purpose of using a muffle furnace to fire Al2O3 ceramic shells at 1050°C? Enhance Strength and Purity

- How do chamber dimensions impact the selection of a muffle furnace? Optimize Heating and Save Costs

- What materials can crucible furnaces melt? A Guide to Metals, Glass & Advanced Materials

- What experimental conditions does an industrial high-temperature muffle furnace provide for thermal stress testing?

- What is the mechanism for the furnace door in a muffle furnace? Discover the Double-Hinge Design for Perfect Sealing