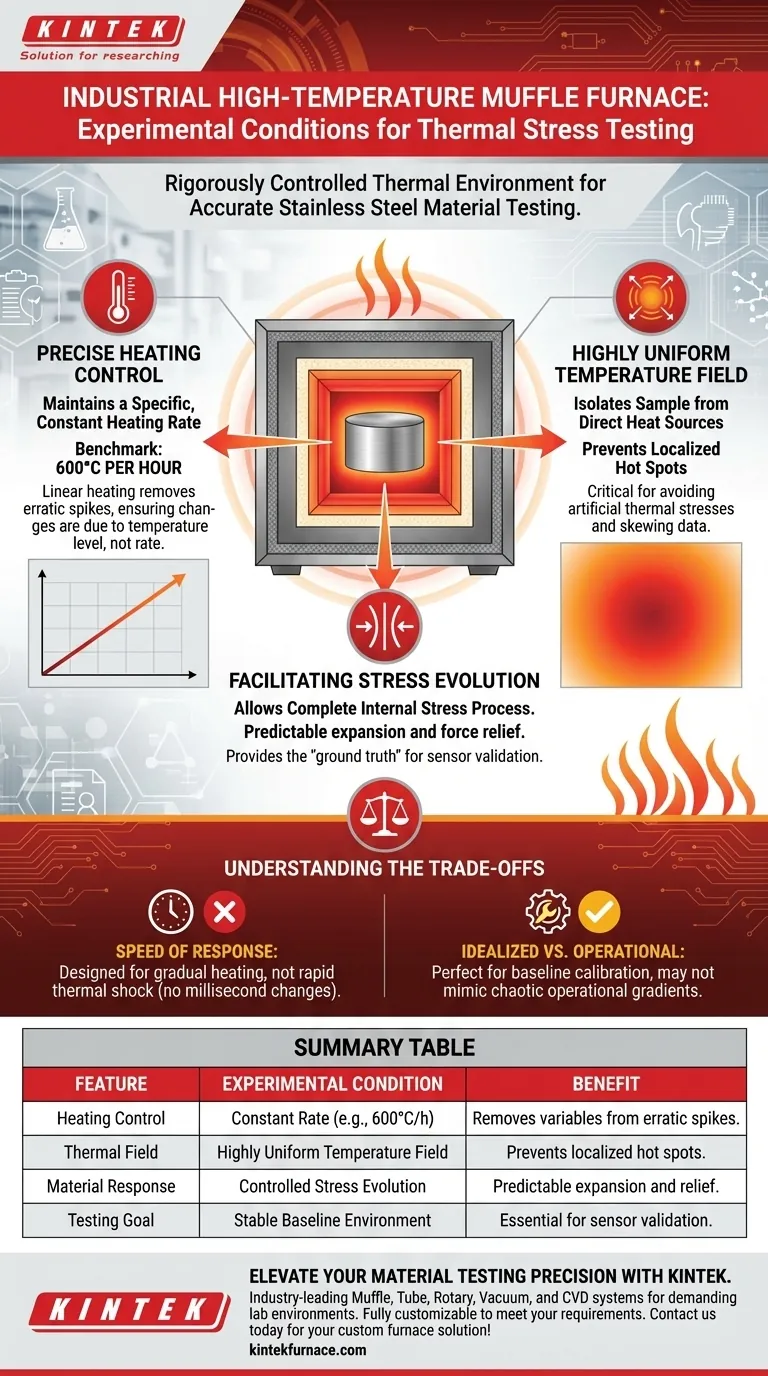

An industrial high-temperature muffle furnace creates a rigorously controlled thermal environment essential for accurate material testing. It primarily provides a highly uniform temperature field and a precise, constant heating rate, such as 600°C per hour, to ensure consistent thermal exposure.

The primary value of the muffle furnace lies in its ability to facilitate a complete internal stress evolution process within stainless steel. By minimizing thermal gradients and fluctuations, it provides the stable baseline necessary for validating real-time sensor monitoring capabilities.

Key Environmental Conditions

Precise Heating Control

The furnace is capable of maintaining a specific, constant heating rate.

A standard benchmark for these experiments is a rate of 600°C per hour.

This linearity removes the variable of erratic temperature spikes, ensuring that any changes in the material are due to the temperature level itself, not the rate of change.

Highly Uniform Temperature Field

Unlike direct flame or induction heating, a muffle furnace isolates the sample from the heat source elements.

This creates a highly uniform temperature field around the stainless steel specimen.

Uniformity is critical because it prevents localized hot spots, which would induce artificial thermal stresses and skew the data regarding the material's natural stress evolution.

Facilitating Stress Evolution

The combination of uniform heat and controlled rates allows the stainless steel to undergo a complete internal stress evolution process.

The material expands and relieves internal forces in a predictable manner.

This controlled evolution is the "ground truth" required to verify that monitoring sensors are functioning correctly under actual heat treatment conditions.

Understanding the Trade-offs

The Speed of Response

While the muffle furnace excels at uniformity, it is designed for gradual, controlled heating.

It may not be suitable for experiments requiring rapid thermal shock or instantaneous heating, as the thermal mass of the furnace prevents millisecond-level temperature changes.

Idealized vs. Operational Conditions

The conditions inside the furnace are highly idealized compared to some industrial operational environments.

While this is perfect for sensor validation and baseline calibration, it may not perfectly mimic the chaotic thermal gradients found in less controlled processing environments.

Making the Right Choice for Your Goal

To maximize the value of your thermal stress testing, align the furnace capabilities with your specific objective:

- If your primary focus is Sensor Validation: Rely on the uniform temperature field to rule out external noise, ensuring your sensor readings reflect actual material changes.

- If your primary focus is Material Characterization: Utilize the constant heating rate (e.g., 600°C/h) to capture the full, uninterrupted lifecycle of internal stress evolution.

The muffle furnace is the definitive tool for establishing a stable, reproducible thermal baseline for stress analysis.

Summary Table:

| Feature | Experimental Condition Provided | Benefit for Stress Testing |

|---|---|---|

| Heating Control | Constant Rate (e.g., 600°C/hour) | Removes variables from erratic temperature spikes |

| Thermal Field | Highly Uniform Temperature Field | Prevents localized hot spots and artificial stresses |

| Material Response | Controlled Internal Stress Evolution | Allows predictable expansion and force relief |

| Testing Goal | Stable Baseline Environment | Essential for sensor validation and material calibration |

Elevate Your Material Testing Precision with KINTEK

Are you looking to achieve the perfect thermal baseline for your stainless steel stress analysis? KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the most demanding lab environments. Backed by expert R&D and precision manufacturing, our high-temperature furnaces are fully customizable to meet your specific heating rates and uniformity requirements.

Don't compromise on your data accuracy—partner with the experts in thermal processing. Contact us today to find your custom furnace solution!

Visual Guide

References

- Kaiyue Qi, Peng Li. Monitoring of Internal Stress in Stainless Steel Materials at High Temperatures Using Optical FPI and LPFG. DOI: 10.58286/30974

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How is an industrial muffle furnace used to assess the ash content of biomass fibers? Master High-Temp Calcination

- What is the difference between a retort and a muffle furnace? Choose the Right Atmosphere-Controlled Furnace

- What is the role of a high-temperature muffle furnace in solid-state synthesis? Master CaMnO3 Perovskite Production

- Why is controlled heat treatment in a muffle furnace necessary for calcined clay? Achieve Optimal Pozzolanic Activity

- What types of heat transfer occur in a box-type resistance furnace? Master Radiation and Convection for Optimal Heating

- What role does a muffle furnace play in the SHS of lithium orthosilicate? Efficient Thermal Ignition Explained

- What role does a precision muffle furnace play in the homogenization treatment of aluminum alloys? | Expert Guide

- What role does a high-temperature muffle furnace play in the component analysis of Moringa oleifera seeds?