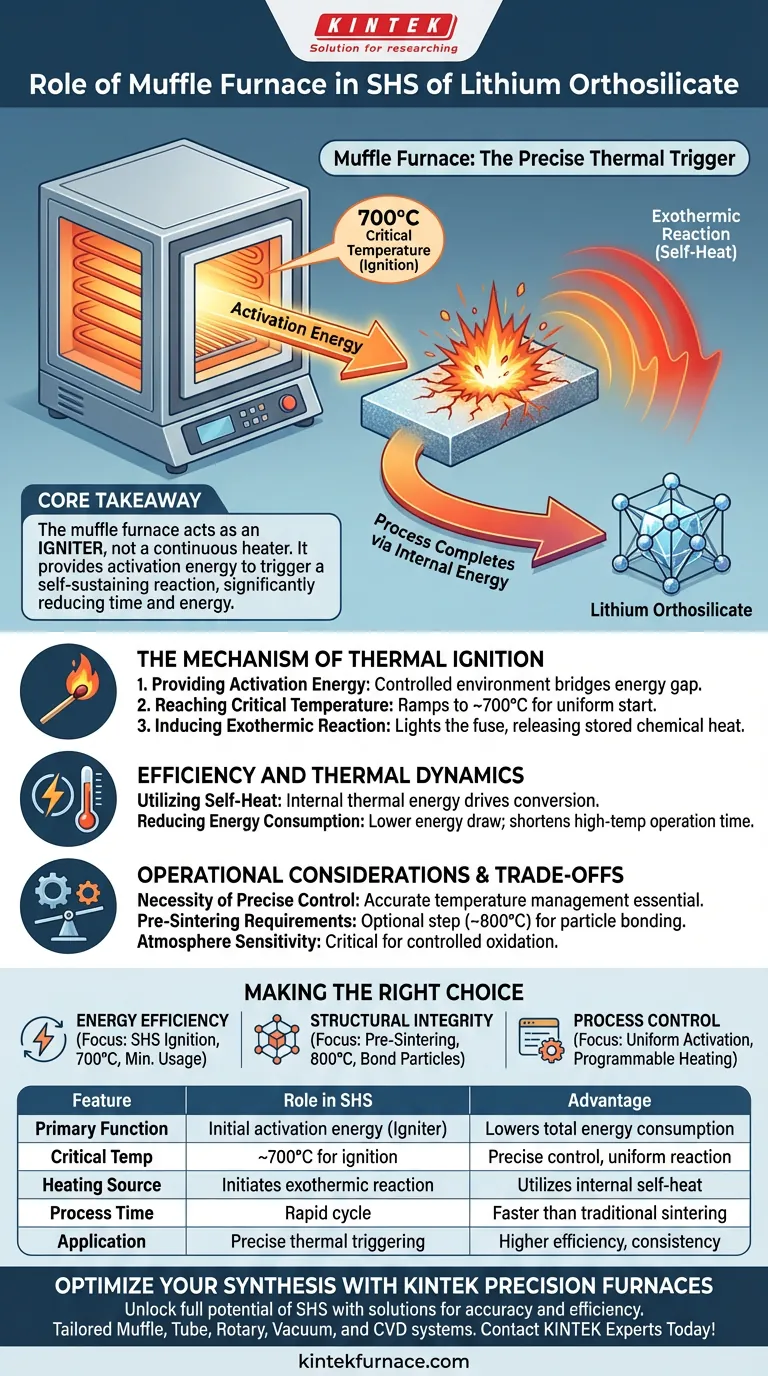

The muffle furnace serves as the precise thermal trigger for the synthesis process. Its primary function is not to supply heat for the entire duration of the reaction, but rather to provide the initial activation energy required to ignite the mixture. By heating the reactants to a critical temperature—typically around 700°C—the furnace induces a self-sustaining combustion reaction that completes the material conversion.

Core Takeaway In Self-Propagating High-Temperature Synthesis (SHS), the muffle furnace acts as an igniter rather than a continuous heater. It raises the system to a critical threshold where an exothermic reaction takes over, utilizing the material's internal chemical energy to finish the synthesis, thereby significantly reducing processing time and external energy consumption.

The Mechanism of Thermal Ignition

The role of the muffle furnace in SHS is distinct from traditional sintering methods. Instead of "baking" the material for hours, it initiates a chemical chain reaction.

Providing Activation Energy

The raw materials for lithium orthosilicate, specifically the metal silicon and oxygen components, require a specific energy input to become reactive. At room temperature, these materials remain inert. The muffle furnace creates a controlled environment to bridge this energy gap.

Reaching the Critical Temperature

The furnace must ramp up to a precise critical point, often cited as 700°C for this specific synthesis. At this temperature, the thermal environment is sufficient to trigger the combustion of the reactants. This precision ensures the reaction starts uniformly rather than sporadically.

Inducing the Exothermic Reaction

Once the critical temperature is reached, the metal silicon reacts with oxygen. This is an exothermic reaction, meaning it releases a significant amount of heat. The furnace effectively lights the fuse, allowing the chemical energy stored in the reactants to take over the process.

Efficiency and Thermal Dynamics

The shift from external heating to internal heat generation is the defining characteristic of this role.

Utilizing Self-Heat

After ignition, the reaction utilizes the released self-heat to propagate through the mixture. This internal thermal energy drives the complete conversion of the precursors into lithium orthosilicate. The furnace does not need to maintain the high reaction temperatures typically required for synthesis; the material heats itself.

Reducing Energy Consumption

Because the furnace is only required to reach the ignition point rather than sustain the peak synthesis temperature, the energy draw is drastically lower. This method significantly shortens the high-temperature operation time compared to conventional solid-state reaction methods.

Operational Considerations and Trade-offs

While the SHS method offers efficiency, the role of the furnace requires strict management to avoid processing errors.

Necessity of Precise Control

The furnace must possess accurate temperature controls. If the temperature fluctuates or overshoots the 700°C target aggressively, the ignition may become uncontrollable or yield inconsistent crystal structures.

Pre-Sintering Requirements

In broader applications involving powder compacts (green compacts), muffle furnaces are also used for pre-sintering (e.g., at 800°C) to facilitate preliminary particle bonding. While this improves structural integrity for handling, it adds an operational step distinct from the rapid SHS ignition.

Atmosphere Sensitivity

While the primary focus is temperature, the presence of oxygen is critical for the reaction with metal silicon. The furnace must maintain an atmosphere that supports this specific oxidation without introducing unwanted contaminants.

Making the Right Choice for Your Goal

When selecting a furnace or defining your process parameters for lithium orthosilicate, consider your primary objective.

- If your primary focus is Energy Efficiency: Utilize the furnace strictly for SHS ignition (around 700°C), relying on the material's exothermic reaction to minimize electricity usage and cycle time.

- If your primary focus is Structural Integrity: Consider a pre-sintering stage (around 800°C) within the furnace to bond powder particles before the final densification or synthesis steps.

- If your primary focus is Process Control: Ensure your furnace features programmable heating rates to prevent thermal shock and ensure the activation energy is delivered uniformly across the sample.

By treating the muffle furnace as a precision ignition tool rather than a simple oven, you maximize the chemical potential of the reactants while minimizing operational costs.

Summary Table:

| Feature | Role in SHS (Lithium Orthosilicate) | Advantage |

|---|---|---|

| Primary Function | Provides initial activation energy (Igniter) | Lowers total energy consumption |

| Critical Temp | Typically ~700°C for ignition | Precise control ensures uniform reaction |

| Heating Source | Initiates exothermic chemical reaction | Utilizes internal self-heat to finish synthesis |

| Process Time | Rapid cycle following ignition | Significantly faster than traditional sintering |

| Application | Precise thermal triggering & pre-sintering | Higher efficiency and material consistency |

Optimize Your Synthesis with KINTEK Precision Furnaces

Unlock the full potential of Self-Propagating High-Temperature Synthesis (SHS) with heating solutions designed for accuracy and efficiency. At KINTEK, we understand that lithium orthosilicate production requires more than just heat—it requires a precise thermal trigger.

Backed by expert R&D and world-class manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your laboratory's specific high-temperature needs. Whether you require rapid ignition at 700°C or controlled pre-sintering at 800°C, our customizable furnaces ensure uniform activation energy and superior process control.

Ready to elevate your material research? Contact KINTEK Experts Today to find the perfect high-temp system for your unique application!

Visual Guide

References

- Kağan Benzeşik, Onuralp Yücel. Thermodynamic Investigations for Combustion-Assisted Synthesis of Lithium Orthosilicate Powders. DOI: 10.1007/s40831-024-00811-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How do muffle furnaces benefit the paint industry? Enhance Paint Testing with Precision Heat Control

- Why is a muffle furnace used to determine the ash content of biochar? Master Your Material Purity Analysis

- What are the uses of box type electric furnaces in chemical engineering? Unlock Precise Heat Control for Your Lab

- How do box type resistance furnaces contribute to catalytic material preparation? Unlock Precision in Catalyst Synthesis

- What maintenance practices extend a muffle furnace's lifespan? Boost Reliability with Proactive Care

- What role does a box laboratory furnace play in tungsten-doped germanium telluride? Master Melting & Annealing

- How should materials be selected for use in a Muffle furnace? Optimize Your High-Temperature Processes

- What types of processes can modern muffle furnaces support? Discover Versatile High-Temperature Solutions