In the paint and coatings industry, a muffle furnace is a laboratory instrument used for critical analysis, not large-scale production. Its primary function is to provide a controlled, high-temperature environment to rapidly dry, cure, or incinerate paint samples. This accelerated process allows manufacturers to efficiently test and verify key performance characteristics like chemical composition, durability, and heat resistance without waiting for lengthy natural curing times.

A muffle furnace's core value is its ability to create a clean, precisely controlled high-heat environment. This isolates the paint sample from contamination, enabling rapid and repeatable analysis of a coating's fundamental properties, from its inorganic content to its performance under extreme thermal stress.

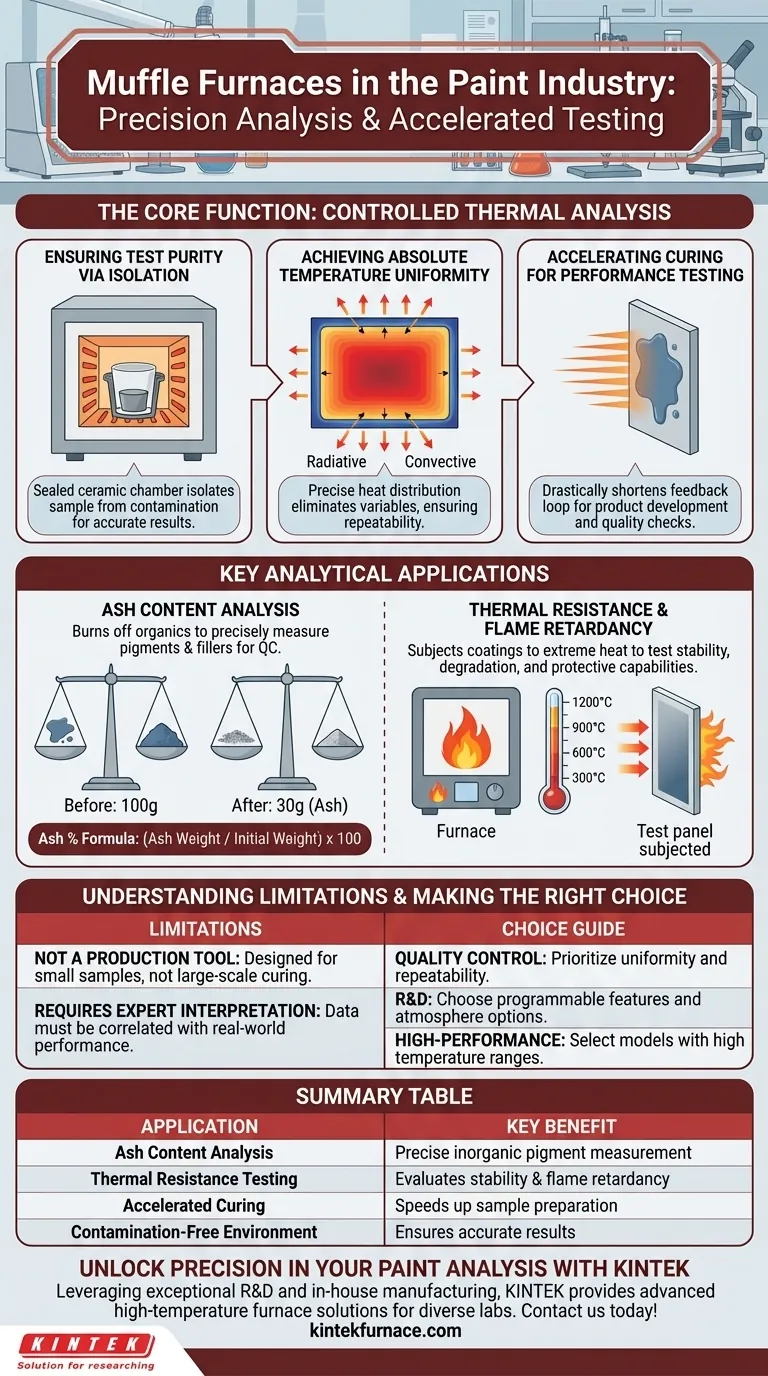

The Core Function: Controlled Thermal Analysis

A muffle furnace is fundamentally a tool for understanding how a coating behaves when subjected to heat. This is achieved through three key features that are critical for reliable laboratory testing.

Ensuring Test Purity via Isolation

The defining feature of a muffle furnace is the muffle itself—a separate, sealed chamber typically made of ceramic. This chamber isolates the paint sample from the heating elements and any potential byproducts of combustion.

This isolation is non-negotiable for accurate analysis. It guarantees that any observed changes in the paint are a direct result of the programmed temperature, not due to reactions with external contaminants.

Achieving Absolute Temperature Uniformity

For a test to be valid and repeatable, every part of the paint sample must experience the exact same temperature. Muffle furnaces are engineered to provide exceptionally uniform heat distribution through both radiative and convective heat transfer.

This precision eliminates variables, ensuring that a test performed today on a sample will yield the same results as a test on the same batch next month.

Accelerating Curing for Performance Testing

While the furnace isn't used for drying on a production line, it is essential for rapidly bringing a sample to its final, fully cured state in the lab.

Once cured, the sample can then undergo further physical testing, such as scratch resistance, adhesion, or flexibility tests. The furnace drastically shortens the feedback loop for product development and quality checks.

Key Analytical Applications Beyond Drying

The true power of a muffle furnace lies in its use as an analytical instrument. It allows technicians to deconstruct a coating to verify its formulation and predict its long-term performance.

Ash Content Analysis

This is one of the most common applications. The furnace is heated to a high temperature (e.g., 500-900°C) to completely burn off all organic components in the paint, such as resins, binders, and solvents.

The material left behind is an inorganic ash, which consists of pigments and fillers. By weighing the sample before and after this process, a lab can precisely determine the ash percentage, a critical quality control metric to verify the batch was formulated correctly.

Testing Thermal Resistance and Flame Retardancy

For high-performance coatings used in the aerospace, automotive, or industrial sectors, understanding their behavior at extreme temperatures is crucial.

A muffle furnace can subject samples to very high heat to test for degradation, discoloration, and overall thermal stability. For intumescent or fire-retardant coatings, it provides the conditions needed to measure their protective capabilities.

Understanding the Limitations

While indispensable in the lab, it's important to recognize what a muffle furnace is not designed for. Understanding its limitations prevents misuse and clarifies its specific role.

Not a Production Tool

Muffle furnaces are precision instruments, not industrial ovens. Their chamber sizes are small, designed for testing small coated panels or crucibles of liquid paint. They are entirely unsuited for curing parts on a manufacturing line.

Requires Expert Interpretation

The data from accelerated testing requires expertise to interpret correctly. A skilled technician must be able to correlate the results from a high-heat test with expected performance in real-world conditions over time. The furnace provides data; the expert provides the insight.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on its intended analytical purpose. Different goals require an emphasis on different features.

- If your primary focus is quality control: You need a furnace with exceptional temperature uniformity and repeatability for consistent ash content analysis.

- If your primary focus is research and development (R&D): Prioritize a furnace with a programmable controller and options for using different atmospheres (e.g., nitrogen) to test novel formulations under varied conditions.

- If your primary focus is high-performance coatings: Look for a model with a very high maximum temperature range (up to 1200°C or more) to accurately test for flame retardancy and thermal stability.

Ultimately, the muffle furnace empowers paint professionals to look inside their coatings, transforming abstract chemical properties into concrete performance data.

Summary Table:

| Application | Key Benefit |

|---|---|

| Ash Content Analysis | Precisely measures inorganic pigment and filler percentages for quality control |

| Thermal Resistance Testing | Evaluates coating stability and flame retardancy under high temperatures |

| Accelerated Curing | Speeds up sample preparation for further physical performance tests |

| Contamination-Free Environment | Ensures accurate results by isolating samples from external factors |

Unlock Precision in Your Paint Analysis with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're focused on quality control, R&D, or high-performance coatings, our furnaces deliver reliable, repeatable results to enhance your lab's efficiency and accuracy.

Contact us today to discuss how our tailored solutions can benefit your specific paint testing needs and drive your innovations forward!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization