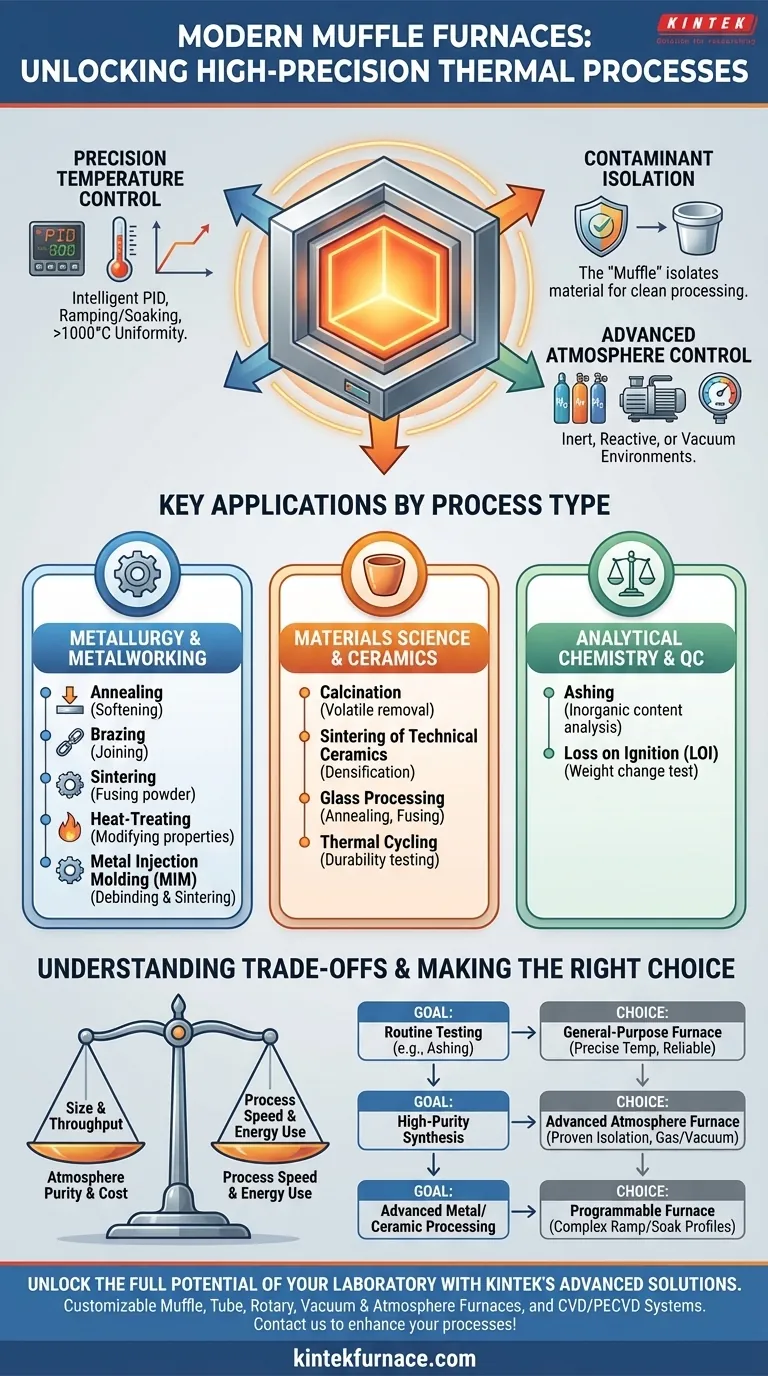

In essence, a modern muffle furnace is a high-precision thermal processing tool. It excels at a wide range of applications, including metallurgical processes like annealing and sintering, materials research on technical ceramics and glass, and analytical chemistry procedures such as ashing. Its core function is to provide an extremely uniform, controllable, and contaminant-free high-temperature environment.

The versatility of a modern muffle furnace stems not from a single feature, but from its ability to precisely control three critical variables: temperature, atmosphere, and purity. This control is what enables its use across dozens of scientific and industrial processes.

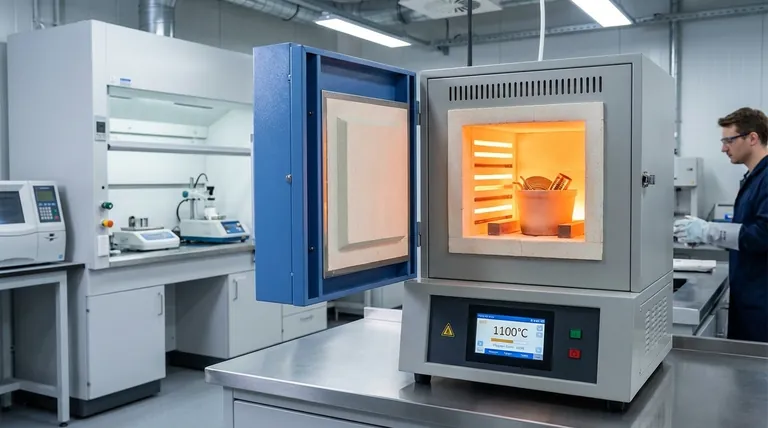

The Core Capabilities of a Modern Muffle Furnace

To understand the processes a muffle furnace can support, you must first understand the fundamental technologies that define it. These features separate it from a simple oven and make it an indispensable laboratory and small-batch production instrument.

Unmatched Temperature Precision and Uniformity

Modern furnaces use intelligent PID (Proportional-Integral-Derivative) controllers to achieve and maintain target temperatures with exceptional accuracy.

These systems allow for complex thermal profiles, including controlled ramping (heating rate), soaking (holding at a specific temperature), and cooling. This is critical for processes where the material's microstructure is sensitive to thermal changes.

With high-efficiency insulation and advanced heating elements, many models can rapidly reach temperatures well over 1000°C while ensuring uniform heat distribution throughout the chamber.

Isolation from Contaminants

The defining feature of a muffle furnace is the "muffle" itself—a chamber that isolates the material being heated from the heating elements and any potential combustion byproducts.

This design ensures that heat is transferred cleanly via radiation or convection, preventing chemical reactions or impurities from contaminating the sample. This is non-negotiable for high-purity materials research and sensitive chemical analysis.

Advanced Atmosphere Control

Many advanced muffle furnaces are not limited to heating in ambient air. They can be equipped with systems to create a tightly controlled atmosphere within the chamber.

This includes purging the chamber with inert gases like nitrogen or argon to prevent oxidation, or using reactive gases like hydrogen for specific chemical reduction processes. Some models even support vacuum conditions to remove all atmospheric variables.

Key Applications by Process Type

The combination of precise temperature, purity, and atmosphere control unlocks a broad spectrum of applications.

Metallurgy and Metalworking

Muffle furnaces are central to developing and treating metal parts. Key processes include:

- Annealing: Heating and slowly cooling metal to reduce hardness and increase ductility.

- Brazing: Joining two pieces of metal using a filler metal at high temperature.

- Sintering: Fusing metal powders together below their melting point to form a solid object.

- Heat-Treating: A broad category of processes used to alter the physical and mechanical properties of a material.

- Metal Injection Molding (MIM): A multi-stage process where the furnace is used for debinding (removing a polymer binder) and final sintering of the metal part.

Materials Science and Ceramics

The development of advanced materials relies on exact thermal processing.

- Calcination: Heating a material to drive off volatile substances, such as converting limestone to lime.

- Sintering of Technical Ceramics: Creating dense, high-strength ceramic parts from powder.

- Glass Processing: Used for annealing, fusing, and creating specialized glass components.

- Thermal Cycling: Subjecting materials to repeated heating and cooling cycles to test their durability and structural integrity.

Analytical Chemistry and Quality Control

The furnace's clean and controlled environment is ideal for preparing or analyzing samples.

- Ashing: Burning off organic material to determine the inorganic content (ash) of a sample. This is common in food science, environmental analysis, and plastics.

- Loss on Ignition (LOI): A quality control test that measures the weight change in a sample after being heated to a high temperature.

Understanding the Trade-offs

While incredibly versatile, muffle furnaces are not a universal solution. Understanding their limitations is key to using them effectively.

Size and Throughput Constraints

Most muffle furnaces are designed for laboratory-scale or small-batch production. They are not typically suited for high-volume, continuous industrial manufacturing, where tunnel kilns or conveyor belt furnaces would be more appropriate.

Atmosphere Purity vs. Cost

Achieving a truly inert or reactive atmosphere requires a furnace with excellent seals, gas delivery systems, and potentially expensive vacuum pumps. The level of atmospheric control needed directly impacts the equipment's complexity and cost.

Process Speed and Energy Use

Modern furnaces are highly energy-efficient, using advanced insulation and intelligent power modes. However, high-temperature processes are inherently energy-intensive. While heating and cooling rates are rapid compared to older models, they are not instantaneous and must be factored into process times.

Making the Right Choice for Your Goal

Your specific application will determine which furnace features are most critical.

- If your primary focus is routine testing like ashing: A general-purpose furnace with precise temperature control and good reliability is sufficient.

- If your primary focus is high-purity material synthesis: Prioritize a furnace with proven chamber isolation and advanced atmosphere (gas or vacuum) capabilities.

- If your primary focus is advanced metal or ceramic processing: You will need a furnace with a sophisticated controller that allows for complex, multi-stage programming of ramp and soak profiles.

Ultimately, the modern muffle furnace is a powerful tool because it gives you precise dominion over the thermal environment.

Summary Table:

| Process Type | Key Applications |

|---|---|

| Metallurgy and Metalworking | Annealing, Brazing, Sintering, Heat-Treating, Metal Injection Molding (MIM) |

| Materials Science and Ceramics | Calcination, Sintering of Technical Ceramics, Glass Processing, Thermal Cycling |

| Analytical Chemistry and Quality Control | Ashing, Loss on Ignition (LOI) |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental needs, whether for metallurgy, materials science, or analytical chemistry. Contact us today to discuss how our tailored solutions can enhance your processes and drive innovation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production