In short, box type resistance furnaces play a dual role in preparing catalytic materials. They are used to thermally process and create high-surface-area catalyst supports, such as alumina (Al₂O₃), and are also essential for the subsequent high-temperature activation steps that give the final catalyst its reactive properties.

The furnace's primary contribution is not simply heat, but the creation of a precisely controlled thermal environment. This control is what allows researchers and engineers to transform precursor materials into a finished catalyst with a specific, high-performance structure.

The Core Function: Creating the Catalyst's Architecture

A catalyst's effectiveness depends on its physical structure and chemical composition. A box furnace provides the critical thermal energy needed to build this architecture from the ground up.

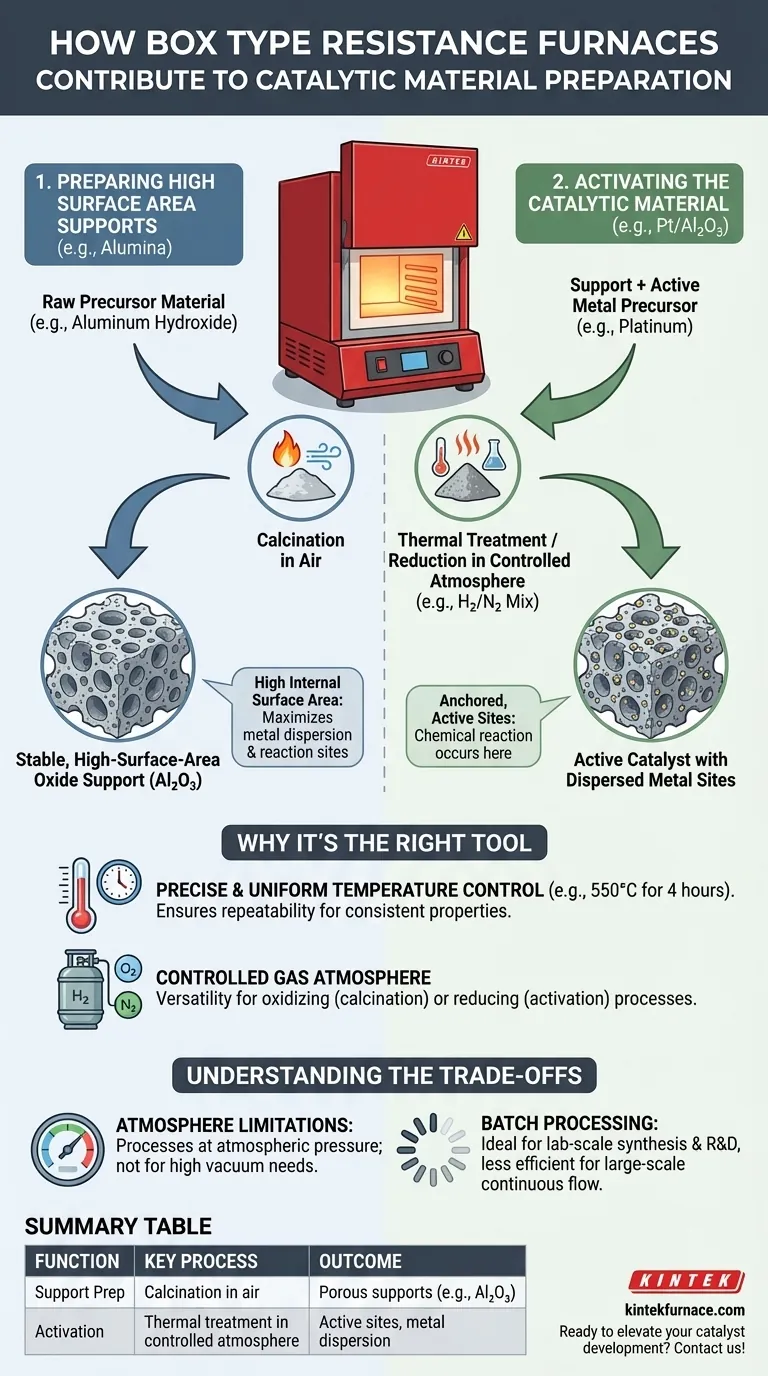

Preparing High Surface Area Supports

Most catalysts consist of tiny active metal particles distributed on a stable, porous foundation known as a support.

The furnace is used for calcination—a high-temperature heating process in the presence of air. This process transforms raw support materials (like aluminum hydroxide) into a stable, high-surface-area oxide, such as alumina (Al₂O₃).

This step is crucial because the vast internal surface area of the support allows for a wide dispersion of the active metal, maximizing the number of reaction sites and, therefore, the catalyst's efficiency.

Activating the Catalytic Material

After the active component (e.g., platinum, palladium) is added to the support, the material is often still in an inactive precursor state.

The box furnace is used again for a final thermal treatment. This step, which can be another calcination or a reduction in a specific gas atmosphere, serves to decompose the precursor, anchor the metal to the support, and create the chemically active sites where the catalytic reaction will occur.

A common example is preparing a Pt/Al₂O₃ catalyst, where the furnace's heat is used to disperse platinum particles across the alumina support, making it effective for decomposing pollutants like Volatile Organic Compounds (VOCs).

Why a Box Furnace is the Right Tool

While many devices can generate heat, a box type resistance furnace offers a combination of features that make it ideal for the precision required in catalyst synthesis.

Precise and Uniform Temperature Control

Catalyst preparation is a science of specifics. The final properties of a support or active site are highly dependent on the exact temperatures used and the duration of heating.

Box furnaces excel at reaching and maintaining a stable, uniform temperature (e.g., holding at 550°C for 4 hours) throughout the chamber, ensuring that the entire batch of material is processed identically. This repeatability is essential for both research and reliable production.

Controlled Gas Atmosphere

The chemical environment during heating is just as important as the temperature. Many activation processes require a specific atmosphere.

While not a vacuum furnace, a box furnace can often be purged with different gases. For example, an oxidizing atmosphere (air) is used for calcination, while a reducing atmosphere (like a nitrogen/hydrogen mix) may be used to convert metal oxides into their pure metallic, active form.

Versatility for Development

These furnaces are workhorses in material science labs. Their operational simplicity and ability to handle different sample sizes make them perfect for experimenting with new catalyst formulations and testing various preparation protocols.

Understanding the Trade-offs

No single tool is perfect for every task. Understanding the furnace's limitations is key to using it effectively.

Atmosphere Limitations

A standard box furnace is designed for processing at or near atmospheric pressure. It cannot achieve the high vacuum needed for synthesizing certain ultra-pure materials or thin films, which is the domain of specialized vacuum furnaces.

Batch Processing Model

Box furnaces operate on a batch basis: you load the material, run the heating cycle, cool it down, and unload it. This is ideal for laboratory-scale synthesis and R&D but is less efficient than continuous-flow reactors for large-scale industrial manufacturing.

A Step in a Larger Process

The furnace provides the thermal treatment, but it is one part of the overall catalyst preparation workflow. Other chemical methods, such as impregnation or co-precipitation, are used to combine the support and active metal precursors before they enter the furnace for final processing.

How to Apply This to Your Catalysis Goal

Your specific use of the furnace will depend on which stage of the catalyst preparation process you are focused on.

- If your primary focus is creating a stable support: You will use the furnace for high-temperature calcination to transform a precursor into a porous, high-surface-area oxide.

- If your primary focus is activating a finished catalyst: You will use the furnace for a precise thermal treatment to decompose a metal precursor and create dispersed, chemically active sites on the support.

- If your primary focus is performance testing: You may use the furnace as a simple reactor to evaluate your catalyst's ability to drive a reaction (like VOC decomposition) at a specific high temperature.

Ultimately, the box type resistance furnace is an indispensable tool, providing the controlled thermal energy required to forge raw ingredients into a high-performance catalyst.

Summary Table:

| Function | Key Process | Outcome |

|---|---|---|

| Support Preparation | Calcination in air | Creates stable, porous supports like alumina (Al₂O₃) with high surface area |

| Catalyst Activation | Thermal treatment in controlled atmosphere | Forms active sites by decomposing precursors and dispersing metals (e.g., Pt) |

| Key Features | Precise temperature control, uniform heating, gas atmosphere versatility | Ensures repeatability and high-performance catalyst structure |

Ready to elevate your catalyst development with tailored thermal solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, whether you're preparing catalyst supports or activating materials. Contact us today to discuss how our furnaces can optimize your catalytic material preparation and drive innovation in your lab!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control