In chemical engineering, a box-type electric furnace is a fundamental tool for conducting high-temperature experiments and small-scale material processing. Its primary uses revolve around creating a precisely controlled thermal environment for tasks like studying chemical reactions, performing pyrolysis, and synthesizing new materials through heat treatment.

The true value of a box furnace in a chemical engineering lab is not just its ability to get hot, but its capacity to provide a stable, uniform, and contained thermal environment. This precision is the key to reproducible research and developing controlled thermal processes.

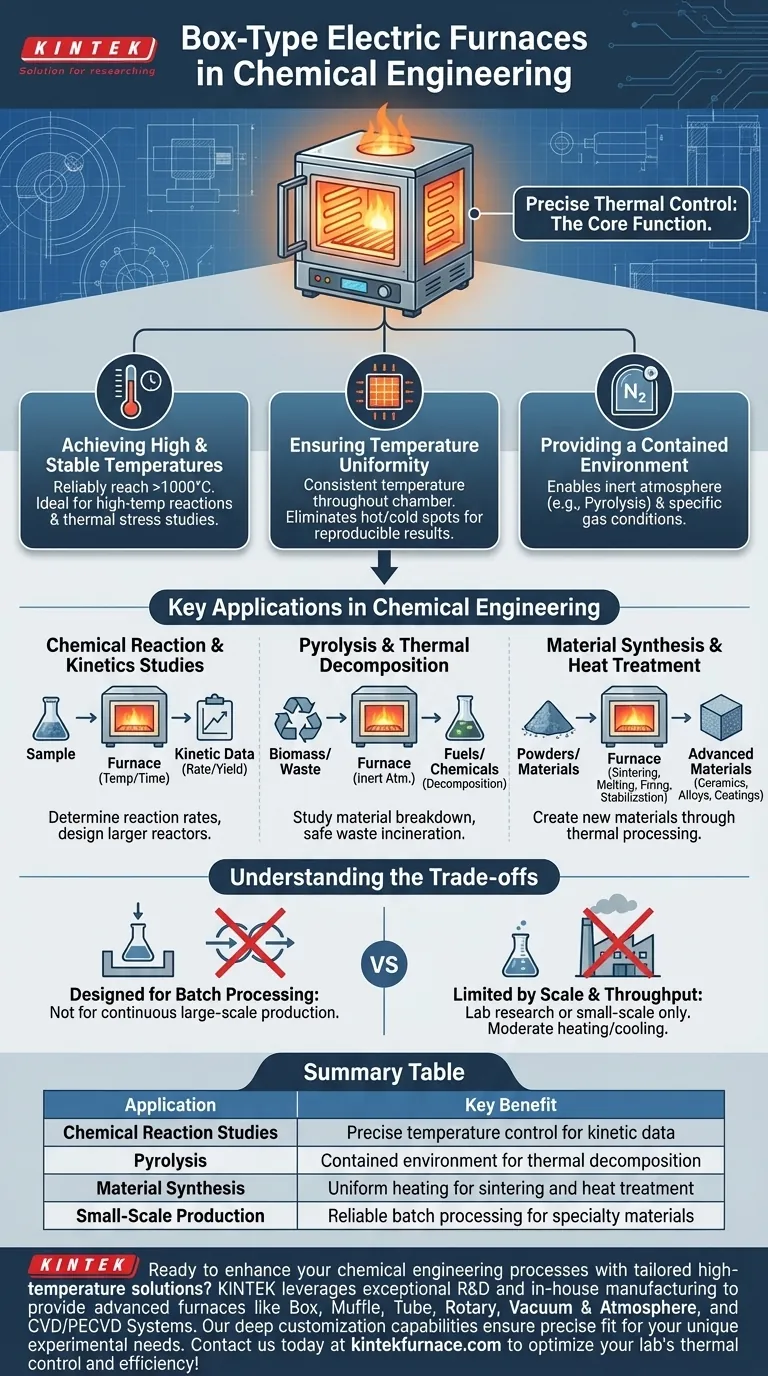

The Core Function: Enabling Precise Thermal Control

A box furnace, at its heart, is an instrument of control. For a chemical engineer, controlling reaction conditions is paramount, and temperature is one of the most critical variables.

Achieving High and Stable Temperatures

Box furnaces are designed to reliably reach and maintain high temperatures, often well over 1000°C. This capability is essential for driving reactions that are not feasible at room temperature or for studying material properties under extreme thermal stress.

Ensuring Temperature Uniformity

A key characteristic of a quality furnace is temperature uniformity. The heating elements are distributed to ensure the entire chamber volume is at the same temperature, eliminating hot or cold spots. This is critical for ensuring that a reaction proceeds at the same rate throughout the sample, leading to consistent product quality and accurate experimental data.

Providing a Contained Environment

The enclosed "box" design allows for a contained atmosphere. This makes it ideal for pyrolysis, which is the thermal decomposition of materials in an inert atmosphere (the absence of oxygen). It also allows for running reactions under specific gaseous conditions that might be required for a particular chemical synthesis.

Key Applications in Chemical Engineering

While the furnace's function is simple—to heat things—its applications are diverse and critical for process development and materials science.

Chemical Reaction and Kinetics Studies

Engineers use these furnaces to determine how temperature affects reaction rates and product yields. By holding a reaction at a specific temperature for a set duration, they can gather the kinetic data needed to design larger-scale chemical reactors.

Pyrolysis and Thermal Decomposition

Pyrolysis is a cornerstone of many modern processes. In a lab, a box furnace is the perfect tool for studying the pyrolysis of biomass, plastics, or waste materials to produce valuable fuels and chemicals. As noted in environmental applications, this extends to the high-temperature incineration of medical waste for safe disposal.

Material Synthesis and Heat Treatment

Many advanced materials in chemical engineering are created through thermal processing. This includes:

- Sintering: Firing powdered materials (like ceramics) at high temperatures to form a solid, dense object.

- Melting: Creating small batches of alloys or glasses for testing.

- Firing: Developing coatings or curing materials on a substrate.

- Stabilization: Using high heat to immobilize hazardous components, such as fixing heavy metals in fly ash by turning it into a stable glass.

Understanding the Trade-offs

While incredibly useful, box furnaces are not a universal solution. Understanding their limitations is crucial for proper application.

Designed for Batch Processing

A box furnace is inherently a batch-processing instrument. You load a sample, run the thermal cycle, and then remove the sample. It is not suitable for the continuous-flow operations typical of large-scale chemical production.

Limited by Scale and Throughput

These furnaces are designed for laboratory research or very small-scale production. Their volume is limited, which makes them impractical for producing large quantities of material.

Heating and Cooling Rates

Standard box furnaces often have moderate heating and cooling rates. While sufficient for most applications, they may not be suitable for experiments requiring extremely rapid thermal quenching or annealing, which would necessitate more specialized equipment.

Making the Right Choice for Your Goal

Selecting the right thermal equipment depends entirely on your objective. A box furnace is a powerful tool when its capabilities are aligned with your experimental or production needs.

- If your primary focus is research and development: Prioritize a furnace with excellent temperature uniformity and a programmable controller to design complex thermal cycles for kinetic studies and material synthesis.

- If your primary focus is small-scale specialty production: Look for a robust, reliable furnace with a simple, user-friendly interface that can consistently repeat a specific thermal recipe.

- If your primary focus is a specific process like pyrolysis: Ensure the furnace is rated for the required temperature and is capable of being sealed to maintain an inert atmosphere.

Ultimately, the box furnace is an essential instrument that empowers engineers to master the effects of heat on chemical systems.

Summary Table:

| Application | Key Benefit |

|---|---|

| Chemical Reaction Studies | Precise temperature control for kinetic data |

| Pyrolysis | Contained environment for thermal decomposition |

| Material Synthesis | Uniform heating for sintering and heat treatment |

| Small-Scale Production | Reliable batch processing for specialty materials |

Ready to enhance your chemical engineering processes with tailored high-temperature solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnaces like Box, Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capabilities ensure precise fit for your unique experimental needs—whether for research, pyrolysis, or material synthesis. Contact us today to discuss how we can optimize your lab's thermal control and efficiency!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are some typical heat processing applications for Box Furnaces? Discover Versatile Solutions for Metals and Materials

- How do modern box type high-temperature resistance furnaces address environmental concerns? Boost Efficiency & Drive Sustainability

- What is the role of precise temperature gradient control in a high-temperature box furnace? Master Mo6S8 Synthesis

- How is a box furnace used in sintering of metal powders? Achieve Dense, High-Strength Metal Parts

- What are the advantages and disadvantages of muffle furnaces? Achieve Contaminant-Free Heating for Sensitive Applications

- What is the function of a high-temperature muffle furnace for NiO thin films? Optimize Gas Sensing Performance

- How does muffle furnace pretreatment of kaolin improve biodiesel synthesis? Boost Transesterification Efficiency Now

- What factors affect the price of muffle furnaces? Key Drivers for Smart Lab Investment