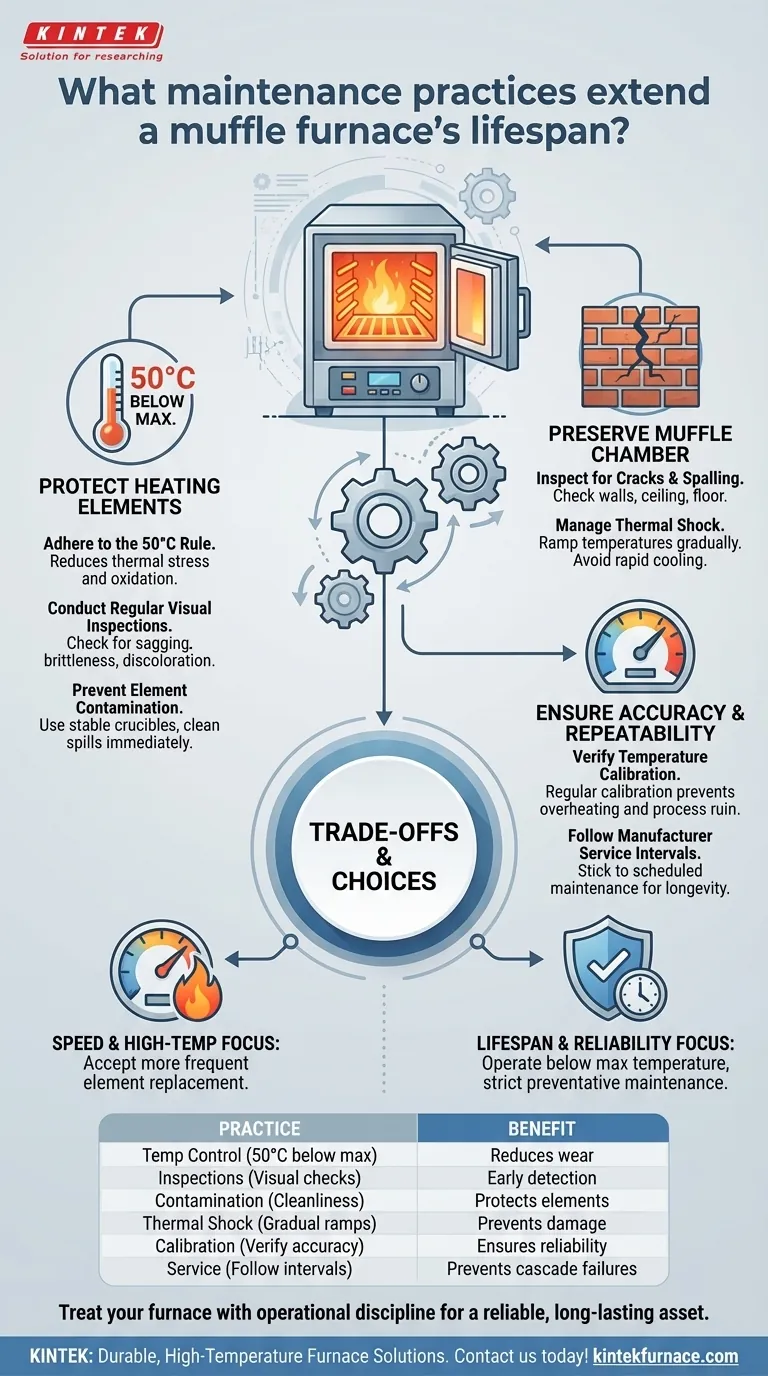

To significantly extend the lifespan of a muffle furnace, you must combine routine physical inspections with disciplined operational habits. This involves regularly checking heating elements and the chamber for wear, verifying temperature accuracy, and strictly adhering to manufacturer service intervals. Crucially, operating the furnace at least 50°C below its maximum rated temperature is one of the most effective strategies for preserving its core components.

The longevity of a muffle furnace is determined less by reactive repairs and more by proactive care. While routine inspections are vital, the daily operational choices you make—specifically avoiding maximum temperature runs and thermal shock—have the most profound impact on preventing premature failure.

Protecting the Heart of the Furnace: The Heating Elements

Heating elements are the most common point of failure in a muffle furnace. Their lifespan is directly tied to a combination of temperature, atmosphere, and physical condition.

Adhere to the 50°C Rule

The single most important practice for element longevity is to operate your furnace below its absolute limit. Running a furnace at its maximum rated temperature is like constantly redlining a car's engine; it causes accelerated wear.

Operating at least 50°C below the maximum temperature dramatically reduces the thermal stress and oxidation rate of the element wiring, significantly extending its service life.

Conduct Regular Visual Inspections

Elements degrade over time. Proactively looking for signs of wear allows you to schedule replacements rather than suffer an unexpected failure during a critical process.

Look for common indicators like sagging, brittleness, or discoloration. Any visible breaks or severe thinning means the element needs immediate attention.

Prevent Element Contamination

Foreign materials can be fatal to heating elements. Spills or even vapors from certain samples can chemically attack the element material, causing it to fail rapidly.

Ensure all samples are placed in appropriate, stable crucibles. Clean any spills or debris from the furnace floor immediately once it has safely cooled down.

Preserving the Core Structure: The Muffle Chamber

The insulating chamber, or "muffle," is critical for temperature stability and efficiency. Damage to the chamber compromises the entire system.

Inspect for Cracks and Spalling

The refractory material of the chamber is susceptible to damage from mechanical stress and repeated heat cycles.

Regularly check the chamber walls, ceiling, and floor for cracks, chipping, or spalling (flaking of the surface). Small cracks can grow, leading to poor insulation, inefficient heating, and potential exposure of the heating elements to damage.

Manage Thermal Shock

Rapid temperature changes create immense stress on the refractory materials, causing them to crack.

Whenever possible, ramp the temperature up and down gradually. Avoid opening the furnace door for extended periods at high temperatures, as the rush of cool air can cause a damaging thermal shock.

Ensuring Accuracy and Repeatability

A long-lasting furnace is only useful if its results are reliable. Calibration and adherence to service schedules ensure the furnace performs as expected.

Verify Temperature Calibration

The thermocouple that reads the internal temperature can drift over time. An uncalibrated furnace may be running much hotter or cooler than the display indicates.

Running hotter than displayed not only ruins process results but also unknowingly over-stresses the heating elements, shortening their life. Regular calibration with a certified meter is essential for both accuracy and longevity.

Follow Manufacturer Service Intervals

Your furnace's operating manual is the definitive guide. It contains a schedule for specific maintenance tasks tailored to your model.

Following these recommendations ensures that wear components are checked and replaced before they can cause a cascade failure, protecting your larger investment.

Understanding the Trade-offs

Every operational decision involves a balance between performance and equipment lifespan.

Performance vs. Longevity

There is a direct trade-off between running at maximum temperature and the life of your heating elements. If a process absolutely requires the furnace's peak temperature, you must accept that element replacement will be a more frequent operational cost. Budget and plan for it accordingly.

Cost of Maintenance vs. Cost of Failure

Preventative maintenance carries a cost in time and parts. However, this cost is almost always lower than the cost of an unexpected, catastrophic failure.

A mid-process failure can lead to lost samples, project delays, and expensive emergency repairs. Routine maintenance is an investment in operational stability.

Making the Right Choice for Your Application

Your maintenance strategy should align with your primary operational goals.

- If your primary focus is maximum lifespan and reliability: Always operate at least 50°C below the maximum temperature and implement a strict preventative maintenance schedule for inspections and calibration.

- If your primary focus is speed and high-temperature processing: Accept that heating elements are a consumable component with a shorter life, and budget for more frequent replacements to avoid unplanned downtime.

Ultimately, treating your furnace with operational discipline is the surest path to ensuring it remains a reliable and long-lasting asset.

Summary Table:

| Maintenance Practice | Key Action | Benefit |

|---|---|---|

| Temperature Control | Operate at least 50°C below max | Reduces thermal stress and element wear |

| Visual Inspections | Check for sagging, brittleness, cracks | Early detection of wear and damage |

| Contamination Prevention | Use stable crucibles, clean spills | Protects heating elements from chemical attack |

| Thermal Shock Management | Ramp temperatures gradually | Prevents refractory cracks and chamber damage |

| Calibration | Verify temperature accuracy regularly | Ensures reliable results and prevents overheating |

| Service Intervals | Follow manufacturer schedules | Prevents cascade failures and ensures longevity |

Ready to enhance your lab's efficiency with a durable muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Don't let equipment failures slow you down—contact us today to discuss how our reliable furnaces can extend lifespan and boost your productivity!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity