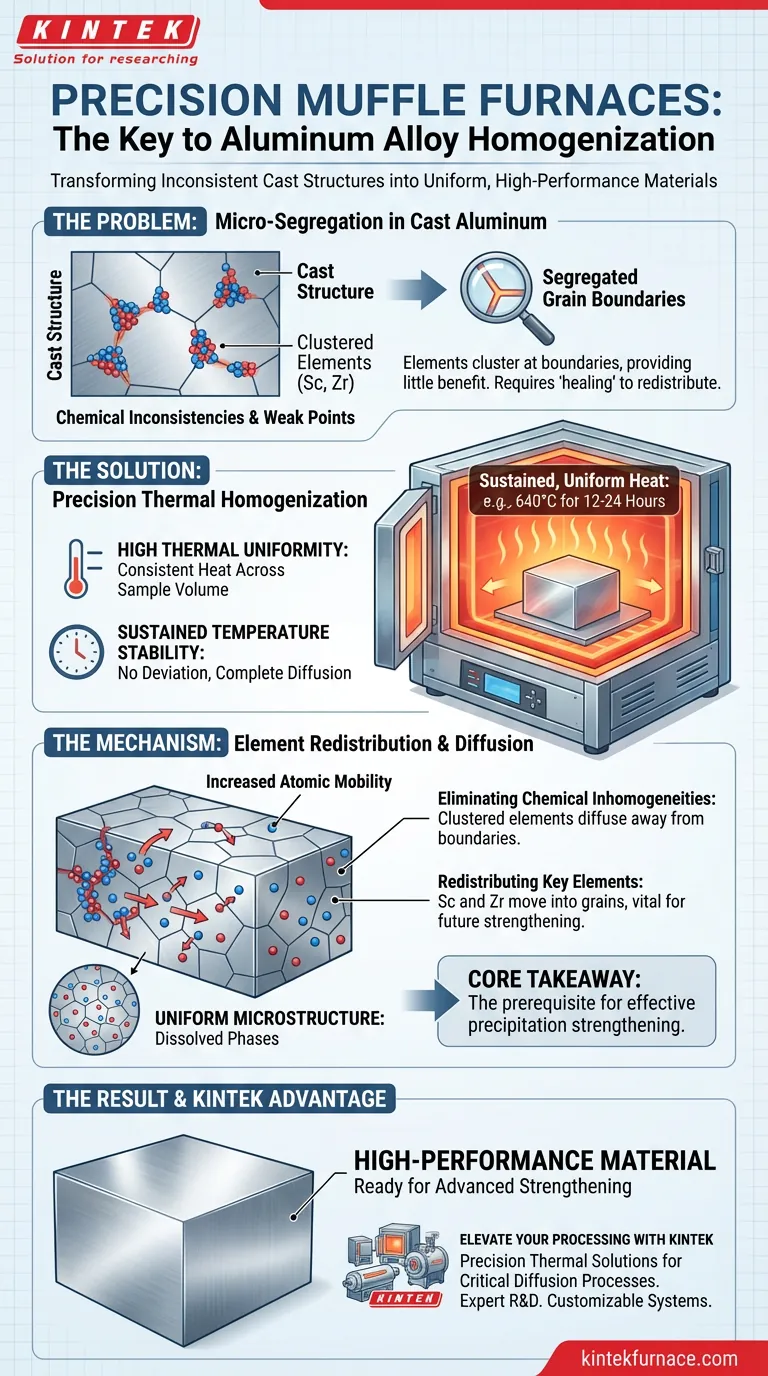

A precision muffle furnace serves as the critical control environment for eliminating chemical segregation in aluminum alloys. Its primary function is to generate a highly uniform thermal field that allows the alloy to be held at specific, elevated temperatures (such as 640°C) for extended periods ranging from 12 to 24 hours. This sustained, even heat drives the diffusion of alloying elements from grain boundaries back into the grain matrix, ensuring a uniform microstructure.

Core Takeaway Homogenization is the process of "healing" the chemical inconsistencies that occur during casting. The precision muffle furnace provides the exact thermal stability required to dissolve clustered elements and redistribute them evenly, which is the prerequisite for effective precipitation strengthening later in the manufacturing process.

The Metallurgy of Homogenization

Eliminating Chemical Inhomogeneities

When aluminum alloys are cast, they often suffer from micro-segregation. This means alloying elements cluster at the grain boundaries rather than being spread effectively throughout the material.

The precision muffle furnace subjects the material to a soak at high temperatures. This thermal energy increases atomic mobility, allowing these clustered elements to diffuse away from the boundaries and dissolve into the primary aluminum matrix.

Redistributing Key Elements

According to metallurgical data, this process is particularly vital for elements like scandium (Sc) and zirconium (Zr).

In an untreated state, these elements may be locked in the grain boundaries where they provide little benefit. The furnace treatment moves them into the grains, preparing the alloy for subsequent hardening processes.

Critical Furnace Capabilities

High Thermal Uniformity

The "precision" aspect of the muffle furnace is non-negotiable.

If the temperature fluctuates or varies across the chamber, diffusion will be uneven. One part of the alloy might be fully homogenized while another remains segregated. The muffle furnace ensures the thermal field is consistent across the entire sample volume.

Sustained Temperature Stability

Homogenization is not a quick process. It requires holding the alloy at temperatures such as 640°C for 12 to 24 hours.

The furnace must maintain this specific setpoint without deviation for the entire duration. This stability ensures that the dissolution of phases is complete without overheating, which could lead to incipient melting or excessive grain growth.

Understanding Process Trade-offs

Time and Energy Consumption

The primary downside to this treatment is the process duration.

Running a furnace at 640°C for up to 24 hours is energy-intensive. It creates a bottleneck in production throughput. However, cutting this time short results in incomplete homogenization, compromising the final mechanical properties of the alloy.

Atmosphere Control

While thermal uniformity is the primary requirement, the internal atmosphere of the furnace is also a factor.

As noted in broader metallurgical contexts, muffle furnaces often provide the ability to control the atmosphere. For aluminum, preventing excessive surface oxidation during these long heat cycles is beneficial, though the primary goal remains the internal redistribution of elements.

Making the Right Choice for Your Goal

To ensure the best results for your aluminum alloy processing, match your equipment capabilities to your specific metallurgical targets.

- If your primary focus is mechanical performance: Prioritize a furnace with the tightest possible thermal uniformity tolerances to ensure complete redistribution of Sc and Zr without overheating.

- If your primary focus is process consistency: Ensure the furnace has programmable controls that can guarantee stability over long soak times (24+ hours) without manual intervention.

The precision muffle furnace transforms an inconsistent cast structure into a uniform, high-performance material ready for advanced strengthening.

Summary Table:

| Feature | Role in Homogenization | Key Benefit |

|---|---|---|

| Thermal Uniformity | Ensures consistent heat across the sample | Eliminates localized micro-segregation |

| Temperature Stability | Sustains heat (e.g., 640°C) for 12-24 hours | Guarantees complete element diffusion |

| Programmable Controls | Automates long-duration soak cycles | Increases process consistency and safety |

| Atmosphere Control | Manages the internal furnace environment | Minimizes surface oxidation during cycles |

Elevate Your Aluminum Processing with KINTEK

Precision is the foundation of high-performance metallurgy. At KINTEK, we understand that incomplete homogenization compromises the integrity of your aluminum alloys. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to provide the ultra-stable thermal environments your lab requires.

Our customizable high-temperature furnaces ensure tight temperature tolerances for critical diffusion processes, enabling you to "heal" chemical inconsistencies and unlock superior material strength. Contact us today to discuss your specific research or production needs and let our experts help you find the perfect thermal solution.

Visual Guide

References

- Mingliang Wang, Haowei Wang. Optimizing the Heat Treatment Method to Improve the Aging Response of Al-Fe-Ni-Sc-Zr Alloys. DOI: 10.3390/ma17081772

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a muffle furnace with precision temperature control contribute to the debinding of alumina ceramic green bodies?

- What is the purpose of an ashing furnace? Essential for Accurate Ash Content Analysis

- What are the safety precautions when connecting power to a new muffle furnace? Ensure Safe Setup for Your Lab

- What are the primary functions of laboratory resistance furnaces in lead refining? Achieve 700°C Thermal Precision

- Why is wearing appropriate clothing important when operating a benchtop furnace? Essential Safety Tips to Prevent Burns and Fires

- How does the built-in venting system in a muffle furnace improve performance? Boost Durability and Safety in Your Lab

- What should be done if the silicon carbon rod in the muffle furnace's resistance furnace ages or underperforms? Expert Tips for Optimal Performance

- What is a muffle furnace and what are its primary uses? Unlock Precise High-Temp Solutions