When a silicon carbide heating element underperforms, the immediate solution is to gradually increase the applied voltage to compensate for its increased electrical resistance. If the furnace still cannot reach the required power or temperature after this adjustment, the element has reached the end of its operational life and must be replaced.

Silicon carbide rods inevitably age by increasing their electrical resistance, which reduces their heat output at a given voltage. While you can compensate by increasing voltage, this is a finite solution. The key to effective furnace management is knowing when to replace elements and, critically, how to do so without creating new heating imbalances.

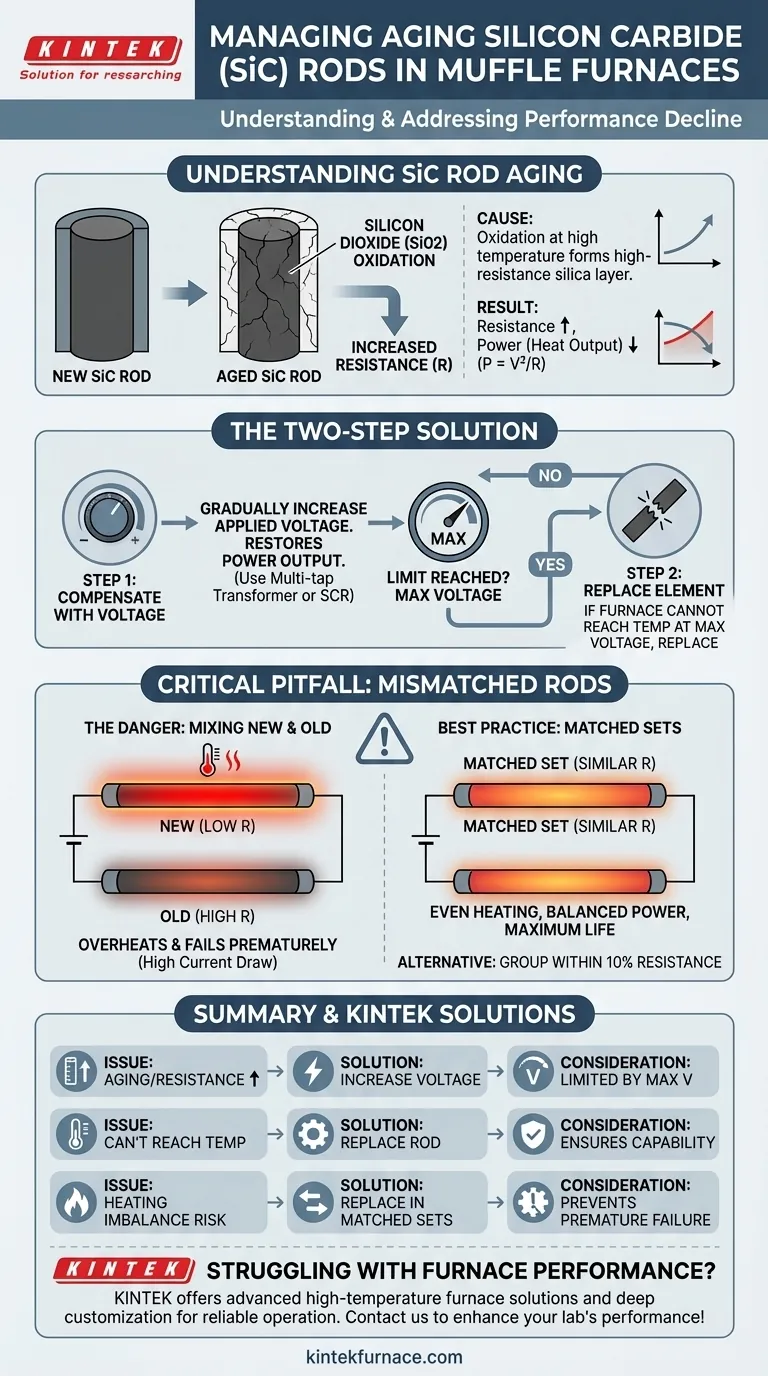

Understanding Silicon Carbide Rod Aging

The "aging" of a silicon carbide (SiC) rod is not a random failure but a predictable physical process. Understanding this sürecin is crucial for proper furnace maintenance and diagnosis.

The Root Cause: Oxidation and Resistance Shift

Silicon carbide is a highly robust material, but at high operating temperatures, it slowly oxidizes. This chemical reaction forms a thin layer of silicon dioxide (silica) on the element's surface.

This silica layer has a higher electrical resistance than the underlying SiC. As the element is used CHCl2 for hundreds or thousands of hours, this oxidation process continues, causing the rod's overall resistance to steadily increase.

The Consequence: Reduced Power Output

The heat generated by a resistive element is defined by the formula P = V²/R (Power = Voltage² / Resistance).

As the rod ages, its resistance (R) increases. If the voltage (V) from the power supply remains constant, the power output (P) žena, leading to a cooler furnace that struggles to reach its setpoint temperature.

The Two-Step Solution in Practice

The references outline a clear, two-step procedure to address this decline in performance. This approach maximizes the useful life of the element before requiring replacement.

Step 1: Compensating with Voltage Adjustment

To counteract the increased resistance, you must increase the applied voltage. This is what "adjusting to the highest level step by step" means. By raising the voltage, you restore the power output to its required level.

Many resistance furnaces are equipped with multi-tap transformers or SCR (Silicon Controlled Rectifier) power controllers specifically for this purpose. You gradually switch to higher voltage taps or increase the SCR output as the elements age.

Step 2: Knowing When to Replace the Element

This strategy has a limit. Eventually, you will reach the maximum voltage output of your power supply.

If the furnace still cannot generate sufficient heat at the highest voltage setting, the rod's resistance has become too high to be compensated for. At this point, replacement इज the only option.

Understanding the Trade-offs: The Dangers of Mismatched Rods

Simply swapping out a failed rod for a new one can seem like a quick fix, but it often creates a more serious problem. This is the most common pitfall in furnace maintenance.

The Problem of Mismatched Resistance

A new SiC rod has a low, factory-specified resistance. A heavily used, aged rod can have a resistance that is two to four times higher.

When you connect elements with vastly different resistances to the same power source (especially in parallel), the new, low-resistance rod will draw a disproportionately large share of the electrical current.

The Result: Premature Failure

This high current会 the new rod to overheat ожидая, significantly exceeding its intended operating temperature. This causes it to age景色 rapidly and fail prematurely, often within a fraction of its expected lifespan.

Meanwhile, the old, high-resistance rods run cooler, worsening the temperature non-uniformity within the furnace.

Best Practice: Replace in Matched Sets

To ensure even heating, balanced power draw, and maximum element life, the best practice is to replace all SiC rods in a furnace at the same time. This guarantees that all elements have a nearly identical resistance.

If budget constraints make this impossible, the next best approach is to measure the resistance of your spare rods and the remaining working rods. Group them so that all elements on a single control zone or circuit have resistances within 10% of each other. Never mix a single new rod with a group of old ones.

Making the Right Choice for Furnace Maintenance

Your strategy for replacing SiC elements depends on your operational priorities.

- If your primary focus is maximum performance and temperature uniformity: Replace the entire set of silicon carbide rods as soon as the furnace struggles to reach temperature, even at maximum voltage.

- If your primary focus is budget optimization and extending inventory: Measure and log the resistance of your rods. Replace them in matched-resistance groups, but avoid mixing new and heavily-aged rods on the same power circuit at all costs.

Proactive management of element resistance is the key to a reliable, efficient, and long-lasting furnace operation.

Summary Table:

| Issue | Solution | Key Consideration |

|---|---|---|

| Aging rod with increased resistance | Gradually increase voltage to compensate | Limited by power supply max voltage |

| Furnace cannot reach temperature after voltage adjustment | Replace the silicon carbide rod | Ensures operational capability |

| Risk of heating imbalances | Replace rods in matched sets or groups with similar resistance | Prevents premature failure and maintains uniformity |

| Budget constraints | Measure rod resistance and group within 10% difference | Avoid mixing new and old rods on same circuit |

Struggling with furnace performance due to aging silicon carbide rods? At KINTEK, we specialize in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental needs, ensuring reliable and efficient furnace operation. Contact us today to discuss how we can enhance your lab's performance and extend the life of your equipment!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element