Connecting a new muffle furnace to power requires a systematic electrical and environmental safety check. This is not a simple plug-and-play operation. For any high-voltage system, especially three-phase 380V power, the connection must be performed by a qualified electrician to verify the supply, ensure proper grounding, and install a dedicated circuit with appropriate overcurrent protection.

A muffle furnace is a powerful industrial heating system, not a household appliance. Safe power connection is less about the final plug and more about ensuring the entire electrical infrastructure—from the building's panel to the furnace itself—is correctly specified, installed, and verified.

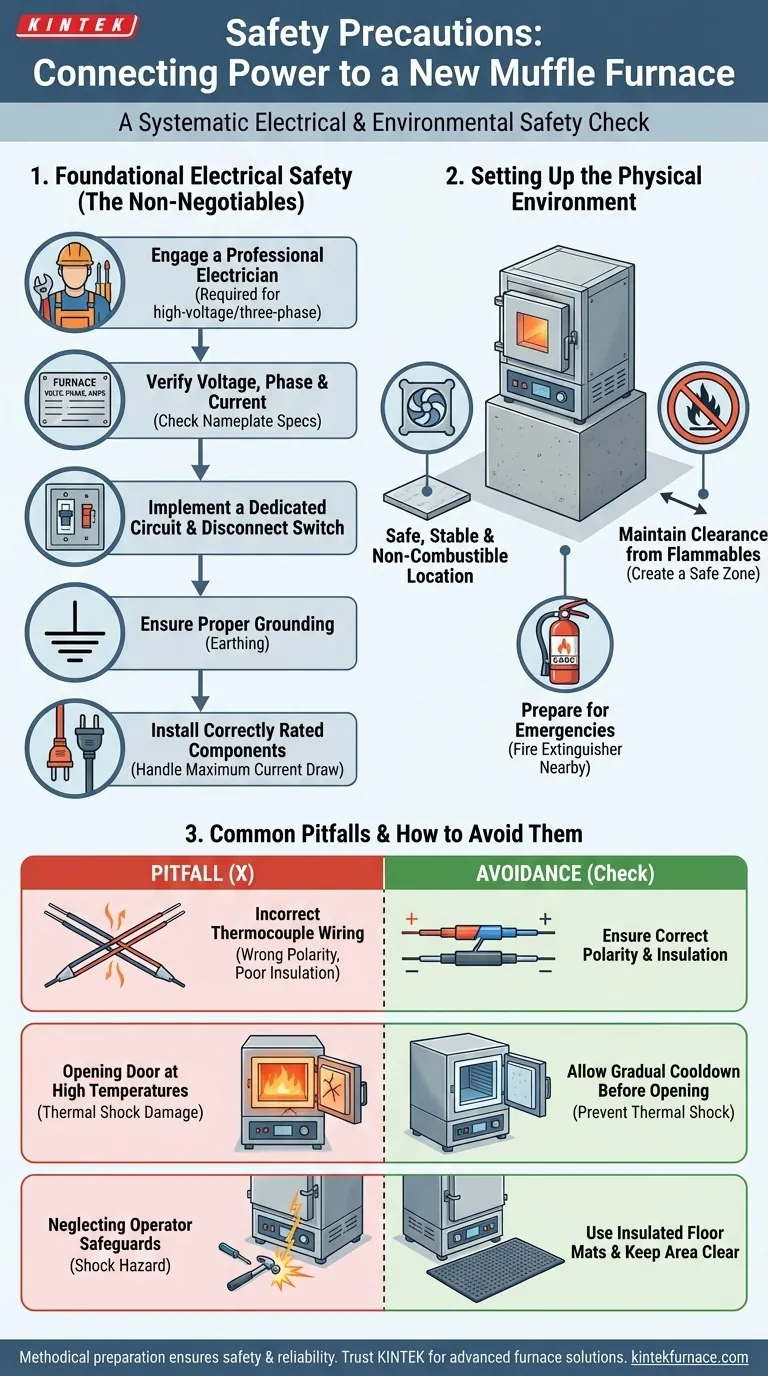

Foundational Electrical Safety: The Non-Negotiables

The initial power connection is the single most critical safety step. Mistakes here can lead to immediate equipment damage, fire, or severe electric shock.

Engage a Professional Electrician

For any furnace, and especially for those requiring a three-phase power supply, installation is not a DIY task. A professional electrician must perform the connection.

They will verify that the building's supply matches the furnace's requirements and ensure all connections comply with local electrical codes.

Verify Voltage and Phase Requirements

Before any connection is made, check the furnace's nameplate. This plate specifies the required voltage (e.g., 240V, 380V), phase (single-phase or three-phase), and current draw (Amps).

Supplying incorrect voltage or phase will damage or destroy the furnace's electrical components and create a significant safety hazard.

Implement a Dedicated Circuit and Disconnect

A muffle furnace must be on its own dedicated circuit. This prevents overloading a shared circuit, which can trip breakers or, in a worst-case scenario, cause a fire.

This circuit must include a dedicated disconnect switch or circuit breaker located near the furnace. This allows for a quick and obvious way to cut all power during an emergency or for maintenance.

Ensure Proper Grounding (Earthing)

The furnace shell and the controller shell must be connected to a verified earth ground wire.

Proper grounding is a critical safety feature that protects operators from electric shock in the event of an internal wiring fault.

Install Correctly Rated Components

All electrical components in the circuit—including plugs, sockets, wiring, and fuses or circuit breakers—must be rated to handle the furnace's maximum current draw.

Using underrated components can cause them to overheat and fail, creating a fire risk.

Setting Up the Physical Environment

Electrical safety is linked to the furnace's physical placement and surroundings. A safe electrical setup in a hazardous environment is still unsafe.

Choose a Safe and Stable Location

The furnace must be placed on a solid, level, and non-combustible surface, such as a concrete floor or a sturdy cement platform.

Ensure the location is well-ventilated but free from excessive drafts that could affect temperature stability.

Maintain Clearance from Flammable Materials

Absolutely no flammable or explosive materials should be stored near the furnace. The intense heat radiated from the unit can ignite combustible items from a distance.

This clear zone should be maintained around all sides of the furnace.

Prepare for Emergencies

A suitable fire extinguisher (typically Class C for electrical fires, but Class ABC is a good general choice) must be located nearby.

All personnel who operate the furnace must know its location and how to use it.

Common Pitfalls and How to Avoid Them

Beyond the initial setup, several common mistakes can compromise safety and lead to equipment failure. Understanding these pitfalls is key to long-term, reliable operation.

Pitfall: Incorrect Thermocouple Wiring

The thermocouple is the furnace's temperature sensor. It is connected to the controller with special compensation wires.

Connecting these wires with the wrong polarity (positive to negative) will cause incorrect temperature readings. This can lead to dangerous overheating, as the controller will not receive accurate feedback. Ensure the gap around the thermocouple entry point is filled with an insulator like asbestos rope to prevent heat loss.

Pitfall: Opening the Door at High Temperatures

Never open the furnace door when the internal temperature is extremely high (e.g., above 600°C), unless required by a specific process. The sudden thermal shock of cool air rushing in can crack the refractory materials lining the furnace chamber.

After a cycle is complete, cut power and allow the furnace to cool gradually. You can open the door just a crack to accelerate cooling before opening it fully.

Pitfall: Neglecting Operator Safeguards

The area directly in front of the furnace is a high-risk zone for dropped tools or crucibles.

Laying a thick, insulated rubber mat on the floor provides an extra layer of protection against electric shock should a fault occur while an operator is present.

Applying This to Your Setup

Your approach should be dictated by your primary responsibility, whether you are managing the facility, overseeing the lab, or operating the equipment.

- If your primary focus is immediate installation safety: Prioritize hiring a qualified electrician to install a dedicated, grounded, and properly protected circuit that matches the furnace's nameplate specifications.

- If your primary focus is long-term operational reliability: Ensure the furnace is placed on a stable, non-combustible surface in a clean environment and that all operators are trained on proper cooldown procedures to prevent thermal shock damage.

- If your primary focus is operator protection: Enforce strict rules about keeping the area clear of flammables, ensure a fire extinguisher is accessible, and use physical safeguards like insulated floor mats.

A methodical and professional approach to the initial power connection is the foundation for safe and reliable furnace operation.

Summary Table:

| Safety Precaution | Key Details |

|---|---|

| Professional Electrician | Required for high-voltage systems, ensures code compliance and correct wiring |

| Voltage and Phase Verification | Check nameplate specs to prevent damage and hazards |

| Dedicated Circuit | Prevents overloads, includes disconnect switch for emergencies |

| Proper Grounding | Protects against electric shock from wiring faults |

| Correctly Rated Components | Use components rated for max current to avoid overheating and fire |

| Safe Location | Place on non-combustible surface with good ventilation |

| Clearance from Flammables | Maintain distance to prevent ignition |

| Emergency Preparedness | Keep fire extinguisher nearby and train personnel |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today for expert guidance and reliable equipment tailored to your requirements!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites