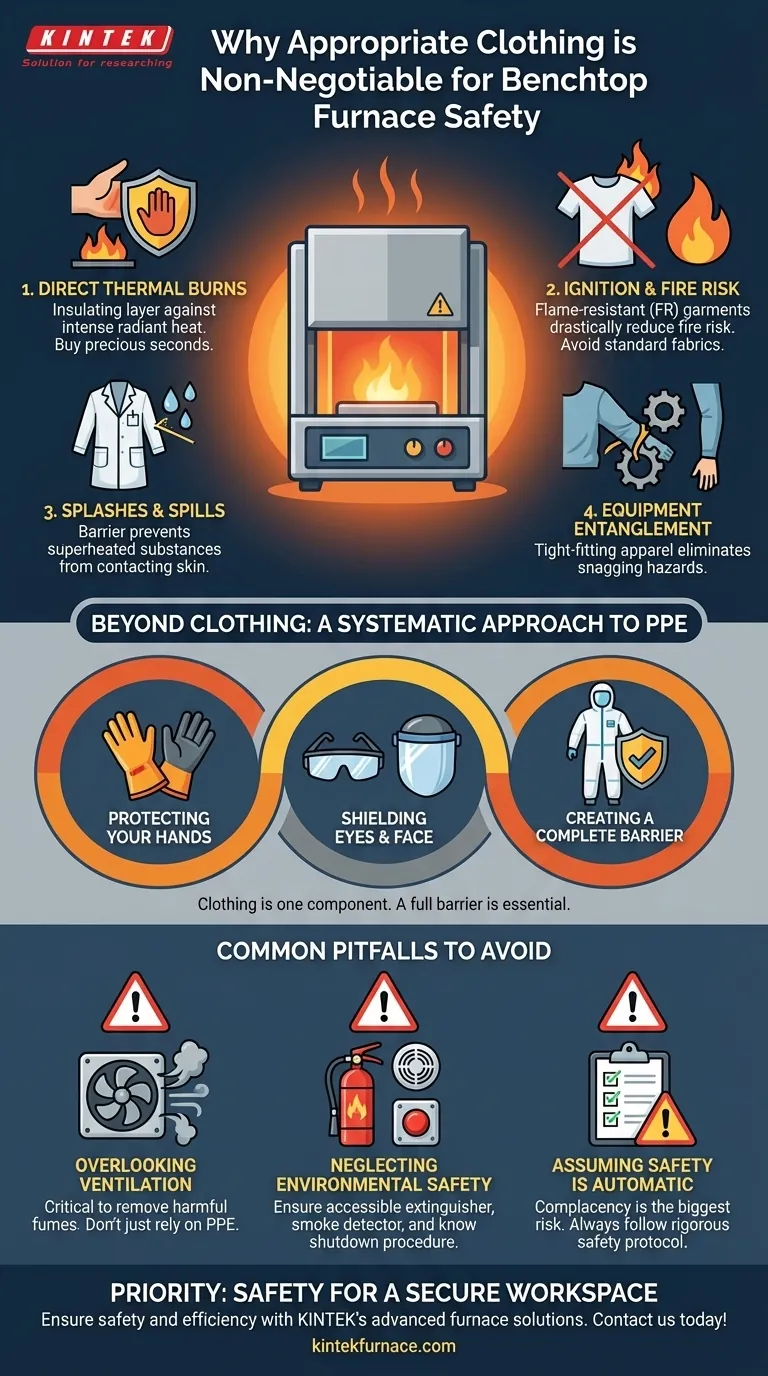

Wearing appropriate clothing when operating a benchtop furnace is a non-negotiable safety requirement for four primary reasons. It provides a critical barrier against severe thermal burns from radiant heat, prevents your own clothes from igniting and causing a fire, shields your skin from the splash or spill of superheated materials, and ensures that loose garments do not get snagged or entangled with the equipment.

Your choice of clothing is the first line of defense in a comprehensive safety system. While it directly protects you, true operational safety is achieved when personal protective equipment (PPE) is combined with an awareness of the surrounding environment and its hazards.

The Primary Hazards Your Clothing Protects Against

The dangers associated with a benchtop furnace extend beyond the obvious heat source. Understanding each specific risk clarifies why clothing choice is not a matter of preference, but of personal safety protocol.

Direct Thermal Burns

A furnace emits intense radiant heat that can cause severe burns even without direct contact. Appropriate, heat-resistant clothing acts as an essential insulating layer, giving you precious seconds to move away from a heat source before injury occurs.

Ignition and Fire Risk

Standard fabrics like cotton or polyester can ignite when exposed to the high temperatures or sparks from a furnace. Wearing tight-fitting, flame-resistant (FR) garments drastically reduces the risk of your clothing catching fire.

Splashes and Spills

The materials you are heating can sometimes splash or spill out of the furnace. Proper lab coats or protective clothing provide a barrier that prevents these superheated substances from making direct contact with your skin.

Equipment Entanglement

Loose sleeves, drawstrings, neckties, or even long hair can easily become caught on the furnace door, controls, or nearby equipment. This can pull you toward the heat source or cause a spill, leading to a serious accident. Tight-fitting apparel eliminates this hazard.

Beyond Clothing: A Systematic Approach to PPE

Viewing your clothing in isolation is a mistake. It is one component of a complete Personal Protective Equipment (PPE) system designed to create a full barrier between you and potential harm.

Protecting Your Hands

Your hands are often closest to the heat source. Heat-resistant gloves are mandatory for handling any items being placed into or removed from the furnace.

Shielding Your Eyes and Face

Sparks, airborne debris, or splashes can cause permanent eye damage. Safety glasses or goggles are the minimum requirement. For procedures with a higher risk of splashing, a full face shield should be worn over your safety glasses.

Creating a Complete Barrier

Each piece of PPE works in concert. Your flame-resistant coat protects your torso, your gloves protect your hands, and your goggles protect your eyes. A failure in one area compromises the entire system.

Common Pitfalls to Avoid

Even with the right PPE, operators can fall into a false sense of security. True safety requires a holistic view of the workspace and a disciplined mindset.

Overlooking Ventilation

PPE protects you from external hazards, but it does not protect you from what you breathe. Proper ventilation is critical to remove harmful fumes, gases, or smoke generated during the heating process, which can pose a significant respiratory risk.

Neglecting Environmental Safety

Your personal gear is only half the equation. You must also ensure the environment is safe. This includes having a fire extinguisher rated for electrical fires within reach, installing a smoke detector, and knowing the furnace's emergency shutdown procedure by heart.

Assuming Safety is Automatic

The most significant risk is complacency. Never assume a procedure is safe just because you have done it many times. Treat every furnace operation with the same rigorous attention to safety protocol.

Making the Right Choice for Your Goal

Your specific safety actions should align with a comprehensive protocol that covers personal, environmental, and procedural safety before every use.

- If your primary focus is personal protection: Always verify you have a complete set of appropriate PPE—flame-resistant clothing, heat-resistant gloves, and safety glasses—before you begin work.

- If your primary focus is workspace safety: Before powering on the furnace, confirm the ventilation is active, locate the nearest fire extinguisher, and mentally review the emergency shutdown steps.

- If your primary focus is preventing accidents: Treat safety checks as the first, most critical step in your standard operating procedure, not as an afterthought.

Ultimately, prioritizing safety is the foundation of a productive and secure work environment.

Summary Table:

| Hazard Type | Protective Clothing Benefit |

|---|---|

| Thermal Burns | Acts as an insulating barrier against radiant heat |

| Fire Risk | Reduces ignition with flame-resistant materials |

| Splashes and Spills | Prevents skin contact with superheated substances |

| Equipment Entanglement | Eliminates risks from loose garments or accessories |

Ensure your laboratory's safety and efficiency with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your operational safety and performance!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals