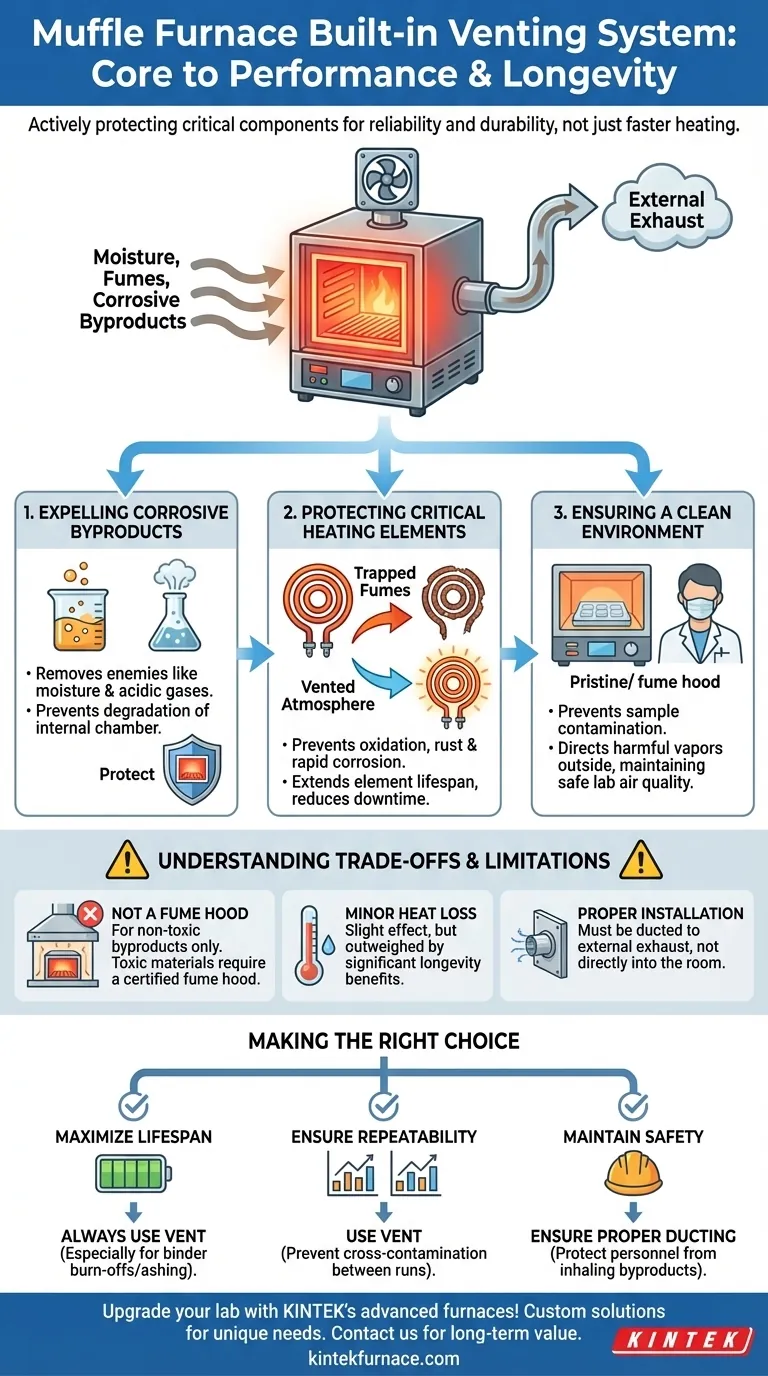

At its core, a built-in venting system improves muffle furnace performance by actively protecting its most critical components from damage. During heating, many materials release moisture, fumes, and corrosive byproducts that, if trapped, will attack and degrade the internal chamber and heating elements. The vent systematically removes these harmful contaminants, ensuring the furnace operates reliably for longer.

The primary role of a muffle furnace vent is not to make it heat faster, but to guarantee its long-term health and operational integrity. It is a protective feature that directly translates to increased durability, reduced maintenance, and a safer lab environment.

The Core Function of a Venting System

A muffle furnace is a sealed, high-temperature chamber. Any substance heated within it will release gases or vapors. Without an exit path, these byproducts create a hostile internal atmosphere that is detrimental to the equipment itself.

Expelling Corrosive Byproducts

Many common furnace applications, like ashing or burning off binders, generate significant moisture and acidic or oxidizing gases.

These substances are the primary enemies of the furnace's internal components. A venting system provides a dedicated pathway to draw them out of the chamber as they are produced.

Protecting Critical Heating Elements

The heating elements are the heart of the furnace, but they are also highly susceptible to damage from chemical attack.

When exposed to trapped moisture and process fumes at high temperatures, elements can oxidize, rust, and corrode rapidly. This leads to premature failure, costly repairs, and significant equipment downtime. A vent directly prevents this by maintaining a cleaner, less reactive atmosphere around the elements.

Ensuring a Clean Operating Environment

The benefits extend beyond just protecting the furnace. Removing fumes and particulates prevents them from settling on the furnace walls or contaminating future samples.

Furthermore, by directing all emitted vapors and gases outside the lab, a properly installed vent is a critical feature for maintaining safe air quality for personnel.

Understanding the Trade-offs and Limitations

While essential, a venting system is not a universal solution for all laboratory exhaust needs. Understanding its purpose and limitations is key to safe and effective operation.

A Vent Is Not a Fume Hood

A standard muffle furnace vent is designed to handle the typical, non-toxic byproducts of common heating processes. It is not a substitute for a fume hood.

If you are working with materials that release toxic, flammable, or highly reactive vapors, the entire furnace must be operated inside a certified fume hood.

Potential for Minor Heat Loss

By design, a vent creates an opening for air to exit the chamber. This can lead to a minor degree of heat loss, potentially affecting the furnace's maximum temperature or heat-up rate slightly.

However, modern furnace designs are engineered to minimize this effect, and the profound benefits for equipment longevity far outweigh this minor inefficiency.

Requires Proper Installation

A venting system is only effective if it is correctly ducted to an external exhaust. Venting directly into the room defeats the purpose of removing contaminants and creates a potential safety hazard for anyone in the laboratory.

Making the Right Choice for Your Process

Use the venting system strategically based on your primary goal for each furnace run. It is an active feature, not a passive one.

- If your primary focus is maximizing equipment lifespan: Always use the vent, especially during binder burn-offs, ashing, or any process known to release moisture or fumes.

- If your primary focus is ensuring process repeatability: Use the vent to create a more stable and clean internal atmosphere, preventing cross-contamination between different sample runs.

- If your primary focus is maintaining a safe laboratory: Ensure the vent is properly ducted to the outside to protect personnel from inhaling process byproducts.

Treating the venting system as an integral part of the furnace's operation is the key to unlocking its full value and ensuring a long service life.

Summary Table:

| Function | Benefit |

|---|---|

| Expels corrosive byproducts | Prevents damage to internal components and heating elements |

| Protects heating elements | Reduces oxidation, rust, and corrosion for longer lifespan |

| Ensures clean operating environment | Minimizes contamination and improves lab air quality |

| Supports safe lab practices | Directs harmful vapors outside, enhancing personnel safety |

Upgrade your laboratory with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs, enhancing durability, safety, and efficiency. Contact us today to discuss how our products can transform your processes and deliver long-term value!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity