In short, the ideal chamber dimensions must be large enough to fully contain your sample within the furnace's constant temperature zone, not just the physical chamber. This critical distinction ensures your material is heated uniformly. Choosing a chamber that is excessively large for your sample, however, leads to significant energy waste and higher operational costs.

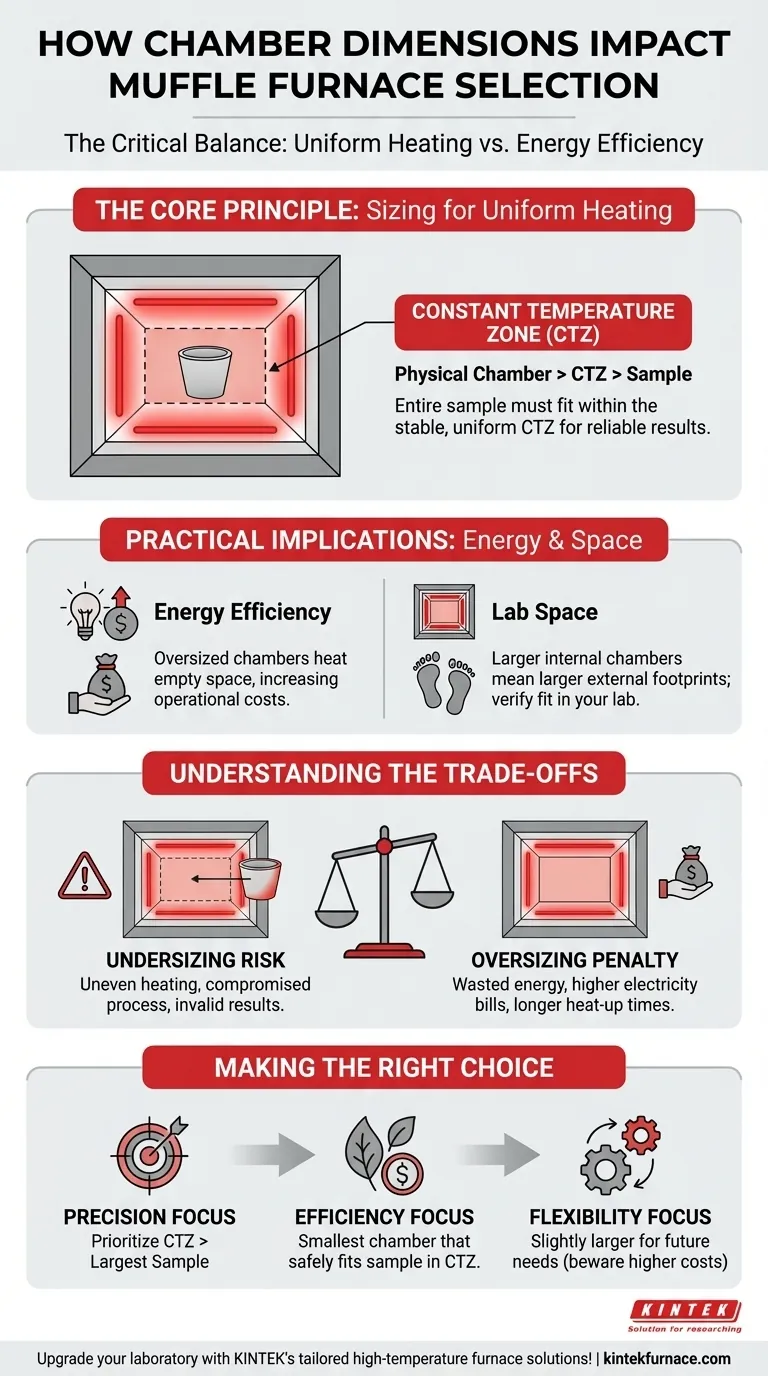

The central challenge is selecting a furnace that guarantees process integrity by providing uniform heat, without paying an unnecessary penalty in energy consumption and lab space for a chamber that is too large.

The Core Principle: Sizing for Uniform Heating

The most common mistake is assuming the entire internal chamber provides a consistent temperature. The reality is more nuanced, and understanding this is key to achieving reliable results.

Accommodating Sample Dimensions

At the most basic level, the furnace chamber must be physically larger than the sample or crucible you intend to heat.

You must account for the length, width, and height of your largest typical workload, ensuring it fits without touching the chamber walls.

The Critical Role of the Constant Temperature Zone

The most important factor is the constant temperature zone, which is the usable volume in the center of thechamber where the temperature is stable and uniform.

This zone is always smaller than the physical chamber dimensions because the areas near the door, walls, and thermocouple are subject to slight temperature variations.

For your process to be successful, your entire sample must fit comfortably inside this uniform heating zone. Failure to do so will result in inconsistent heating and unreliable test results.

The Practical Implications of Chamber Size

Beyond the core heating function, the dimensions you choose have direct consequences for your lab's budget and workflow.

Energy Efficiency and Operational Cost

A larger chamber requires more energy to reach and maintain its setpoint temperature.

If your samples are consistently small but your furnace chamber is large, you are paying to heat empty space. This directly increases operational costs over the lifetime of the furnace.

External Footprint and Lab Space

The internal chamber size directly influences the furnace's external dimensions.

Before selecting a furnace, you must confirm that its physical footprint will fit within your available laboratory space, including necessary clearance for ventilation and user access. A large chamber in a small lab can create significant logistical problems.

Understanding the Trade-offs

Choosing the right chamber size is a balancing act. Both undersizing and oversizing come with significant disadvantages.

The Risk of Undersizing

Choosing a chamber that is too small is a critical error. Your sample may not fit at all, or worse, it may extend beyond the constant temperature zone.

This leads to uneven heating, which can compromise or completely invalidate your process, whether you are ashing, annealing, or performing material analysis.

The Penalty of Oversizing

The primary penalty for an oversized chamber is poor energy efficiency. You will face longer heat-up times and higher electricity bills.

While it may seem wise to buy a larger furnace "just in case," this strategy is only cost-effective if you genuinely anticipate needing the larger capacity in the near future.

Advanced Process Considerations

For some applications, the process itself dictates chamber requirements.

Operations requiring special atmospheres (e.g., inert gas) or specific vacuum levels may necessitate particular chamber structures or materials, which can influence the available size options.

Making the Right Choice for Your Application

Use your primary goal to guide your final decision.

- If your primary focus is precision and repeatability: Prioritize the furnace's specified constant temperature zone, ensuring it is larger than your biggest sample.

- If your primary focus is energy efficiency and cost: Choose the smallest chamber that safely accommodates your sample within its constant temperature zone.

- If your primary focus is future flexibility: Select a slightly larger model, but be fully aware of the higher initial and ongoing energy costs.

Ultimately, a correct assessment of your sample size against the furnace's true uniform heating volume will ensure you make an effective and efficient investment.

Summary Table:

| Factor | Impact on Selection |

|---|---|

| Constant Temperature Zone | Must fully contain sample for uniform heating |

| Sample Dimensions | Ensure fit without touching walls |

| Energy Efficiency | Larger chambers increase operational costs |

| Lab Space | External footprint must fit available area |

| Process Requirements | Influences chamber structure for atmospheres or vacuum |

Upgrade your laboratory with KINTEK's tailored high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with advanced options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how we can optimize your furnace selection for superior performance and cost savings!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?