The door of a muffle furnace typically operates using a movable double-hinge mechanism. This specialized design is not just for opening and closing; it is engineered to move in concert with the furnace body as it expands and contracts under extreme temperatures. This dynamic movement ensures the door maintains a tight, consistent seal against the furnace chamber, which is critical for performance.

The design of a furnace door is fundamentally a solution to a physics problem: how to seal a chamber that physically changes its dimensions due to thermal expansion. The double-hinge mechanism allows the door to "float" and self-adjust, preserving the integrity of the high-temperature, isolated environment inside.

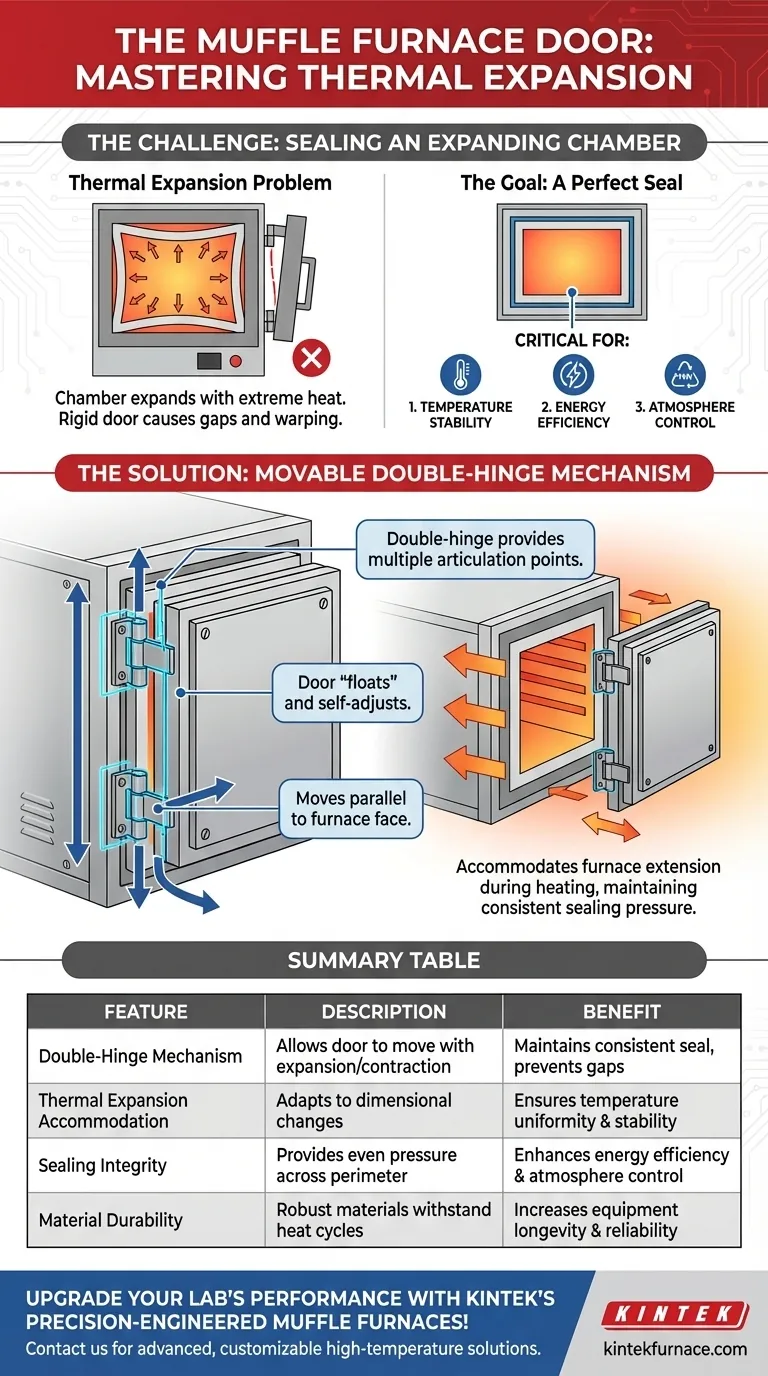

The Core Challenge: Sealing an Expanding Chamber

Muffle furnaces operate at incredibly high temperatures. This heat creates a significant engineering challenge that directly influences the door's design.

The Problem of Thermal Expansion

As the furnace chamber heats up, its materials expand. A rigidly fixed door with a simple hinge cannot accommodate this change.

This mismatch would cause the frame to warp or the door to jam, creating gaps. These gaps compromise the entire purpose of the furnace.

The Goal of a Perfect Seal

A perfect seal is non-negotiable for three reasons:

- Temperature Stability: It prevents heat from escaping and cold air from entering, ensuring a uniform and stable temperature inside.

- Energy Efficiency: A tight seal minimizes heat loss, reducing the energy needed to maintain the target temperature.

- Atmosphere Control: It isolates the sample from the outside environment, which is essential for processes that require a controlled atmosphere without contamination.

How the Double-Hinge Mechanism Works

The movable double-hinge is an elegant solution to the problem of thermal expansion. It allows the door to maintain constant, even pressure against the furnace opening.

The Movable Hinge Design

Unlike a standard door hinge that pivots on a single fixed axis, a double-hinge provides multiple points of articulation. This allows the door to shift slightly up, down, or outward without breaking its seal.

The mechanism allows the door to move parallel to the furnace face, rather than just swinging away from it.

Accommodating Furnace Extension

As the furnace body expands with heat, the front face of the chamber moves slightly. The double-hinge mechanism allows the entire door assembly to travel with this movement.

This ensures the door face remains perfectly flush against the furnace opening, maintaining seal integrity at any temperature.

Ensuring Consistent Sealing Pressure

The design guarantees that pressure is applied evenly across the entire perimeter of the door. This prevents the formation of hot or cold spots near the opening and ensures the most efficient heating possible.

The Door's Role in the Broader System

The door mechanism is not an isolated feature; it is integral to the furnace's core functions of providing indirect, uniform, and controlled heat.

Maintaining Temperature Uniformity

The references note that muffle furnaces operate via thermal radiation and convection to achieve even heat distribution. A poor seal would introduce drafts, creating temperature gradients and ruining uniformity. The double-hinge door prevents this.

Enabling Indirect Heating

A key principle of a muffle furnace is that the sample is heated indirectly by elements in the walls, protecting it from flames or byproducts. The sealed chamber, made possible by the door, is what creates the isolated "muffle" environment required for this to work.

Preventing Heat Loss

Effective insulation is a defining feature of a muffle furnace. The door is the only major break in this insulation. A high-performance sealing mechanism is therefore just as important as the refractory materials lining the chamber walls.

Understanding the Design Considerations

While highly effective, this mechanism involves specific complexities and trade-offs compared to simpler designs.

Mechanical Complexity vs. Simplicity

A double-hinge is mechanically more complex and costly to manufacture than a basic hinge. However, this cost is justified by the vast improvement in temperature stability and process repeatability.

Material Durability

The hinge components themselves are exposed to significant radiated heat. They must be constructed from robust materials that resist deformation and wear over thousands of heating and cooling cycles.

Maintenance and Alignment

Over time, even the best mechanisms can fall out of alignment. Periodic checks are necessary to ensure the door continues to close evenly and provide a perfect seal, as misalignment can negate its benefits.

Why This Mechanism Matters for Your Work

Understanding the furnace door's function helps you optimize your processes and maintain your equipment.

- If your primary focus is process repeatability and accuracy: The double-hinge mechanism is critical because it ensures a stable, consistent heating environment from one run to the next.

- If your primary focus is energy efficiency and operational cost: A properly functioning sealed door directly reduces heat loss, lowering the energy required to maintain high temperatures.

- If your primary focus is equipment longevity: Knowing to check for proper door alignment can help you spot maintenance issues before they compromise the furnace or your results.

Ultimately, the furnace door is not an afterthought but an active component engineered to master the physics of extreme heat.

Summary Table:

| Feature | Description | Benefit |

|---|---|---|

| Double-Hinge Mechanism | Allows door to move with furnace expansion/contraction | Maintains consistent seal and prevents gaps |

| Thermal Expansion Accommodation | Adapts to dimensional changes at high temperatures | Ensures temperature uniformity and stability |

| Sealing Integrity | Provides even pressure across door perimeter | Enhances energy efficiency and atmosphere control |

| Material Durability | Made from robust materials to withstand heat cycles | Increases equipment longevity and reliability |

Upgrade your lab's performance with KINTEK's precision-engineered muffle furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for superior sealing, energy savings, and process repeatability. Contact us today to discuss how our furnaces can optimize your operations!

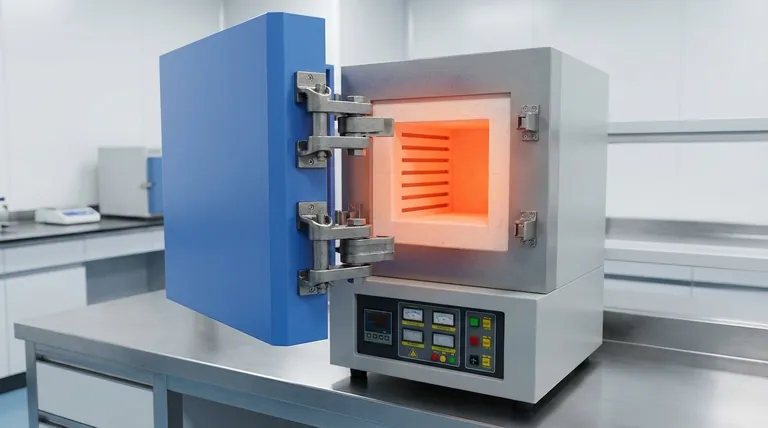

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing