In short, ceramic furnaces are precision tools for fundamentally altering the properties of materials through controlled thermal energy. Their primary applications include sintering, co-firing, annealing, metallizing, flattening, and specialized powder processing. These functions make them essential in the manufacturing of advanced components across the electronics, aerospace, medical, and automotive industries.

A ceramic furnace is not merely an oven; it is a controlled environment for inducing specific, transformative changes in material properties. Its true value lies in the precise management of temperature and atmosphere to achieve desired outcomes like increased density, component bonding, or stress relief.

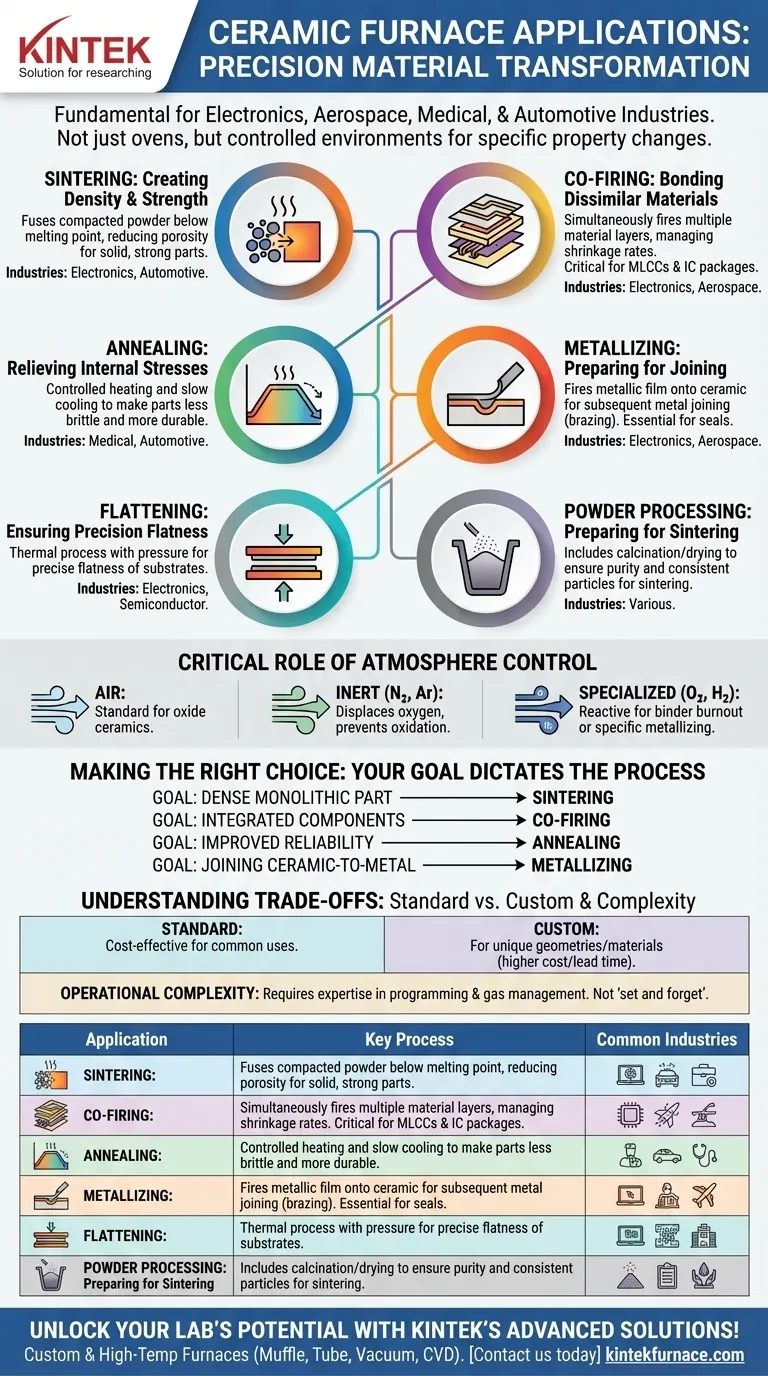

Core Thermal Processes Explained

The "application" of a ceramic furnace is best understood by the specific thermal process it is designed to execute. Each process targets a different material transformation.

Sintering: Creating Density and Strength

Sintering is the process of taking a compacted powder and heating it to a temperature below its melting point.

This causes the individual particles to fuse, reducing porosity and creating a solid, dense, and strong monolithic object. It is the fundamental process for creating most advanced ceramic parts.

Co-firing: Bonding Dissimilar Materials

Co-firing is a specialized form of sintering where multiple, distinct material layers are fired simultaneously. A common example is firing a ceramic substrate with metallic conductive traces.

The primary challenge is managing the different shrinkage rates of the materials to prevent warping or delamination. This process is critical for producing components like multi-layer ceramic capacitors (MLCCs) and integrated circuit packages.

Annealing: Relieving Internal Stresses

Annealing involves heating a material to a specific temperature and then holding it there before cooling it at a very controlled, often slow, rate.

This process relieves internal stresses that may have been introduced during manufacturing, making the final ceramic component less brittle and more durable.

Metallizing: Preparing for Joining

Metallizing is the process of firing a metallic film onto a ceramic surface.

This thin metal layer prepares the ceramic to be joined to a metal component through a subsequent process like brazing. It is essential for creating robust ceramic-to-metal seals used in vacuum tubes, sensors, and high-power electronics.

Flattening and Powder Processing

Flattening is a thermal process, often combined with light pressure, used to ensure the precise flatness of ceramic substrates, which is crucial for semiconductor and electronics applications.

Powder processing is a broader category that includes calcination or drying of powders to prepare them for a later sintering step, ensuring purity and consistent particle characteristics.

The Critical Role of Atmosphere Control

The atmosphere inside the furnace is just as important as the temperature. The gas environment prevents or encourages specific chemical reactions during firing.

Air Atmosphere

An air atmosphere is the standard for firing many oxide ceramics where oxidation is not a concern. It is the simplest and most common operating environment.

Inert Atmospheres (Nitrogen, Argon)

Inert gases like nitrogen or argon are used to displace oxygen and prevent oxidation. This is critical when firing non-oxide ceramics or when co-firing ceramics with easily oxidized metals like copper.

Specialized Atmospheres

In some cases, a reactive atmosphere is required. A pure oxygen environment can be used to ensure the complete burnout of binder materials, while a reducing atmosphere like hydrogen is often necessary for specific metallizing processes.

Understanding the Trade-offs

Selecting a furnace involves more than just knowing the application; it requires understanding the operational constraints and design choices.

Standard vs. Custom Configurations

Standard, off-the-shelf furnaces are cost-effective solutions for common applications with conventional material sizes.

However, unique component geometries, novel materials, or highly specific thermal and atmospheric profiles often demand a custom-designed furnace, which involves higher initial costs and longer lead times.

Operational Complexity

These are not simple "set and forget" devices. Operating a ceramic furnace effectively requires expertise in programming multi-stage temperature profiles and managing complex gas delivery systems.

Operator error or a poorly designed firing profile can easily ruin a batch of high-value components, making process control a critical factor for success.

Making the Right Choice for Your Goal

Your end goal dictates the type of furnace process you require.

- If your primary focus is creating a dense, monolithic ceramic part: You need a sintering furnace with excellent temperature uniformity to ensure consistent densification.

- If your primary focus is manufacturing integrated electronic components: A co-firing furnace with precise atmospheric control is essential for successfully bonding ceramics and conductive metals.

- If your primary focus is improving the mechanical reliability of a finished part: An annealing furnace with programmable cooling rates is the correct tool to relieve internal stress.

- If your primary focus is joining a ceramic component to a metal one: Your process requires a metallizing furnace, often operating with specific gas mixtures to create a bondable surface.

Understanding these core applications and their requirements is the first step toward leveraging thermal processing to achieve your material engineering objectives.

Summary Table:

| Application | Key Process | Common Industries |

|---|---|---|

| Sintering | Fuses powders for density and strength | Electronics, Automotive |

| Co-firing | Bonds dissimilar materials simultaneously | Electronics, Aerospace |

| Annealing | Relieves internal stresses for durability | Medical, Automotive |

| Metallizing | Applies metal films for joining | Electronics, Aerospace |

| Flattening | Ensures flatness of substrates | Electronics, Semiconductor |

| Powder Processing | Prepares powders for sintering | Various manufacturing |

Unlock the full potential of your laboratory with KINTEK's advanced ceramic furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, enhancing efficiency and results in electronics, aerospace, medical, and automotive applications. Contact us today to discuss how we can tailor a solution for you!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations