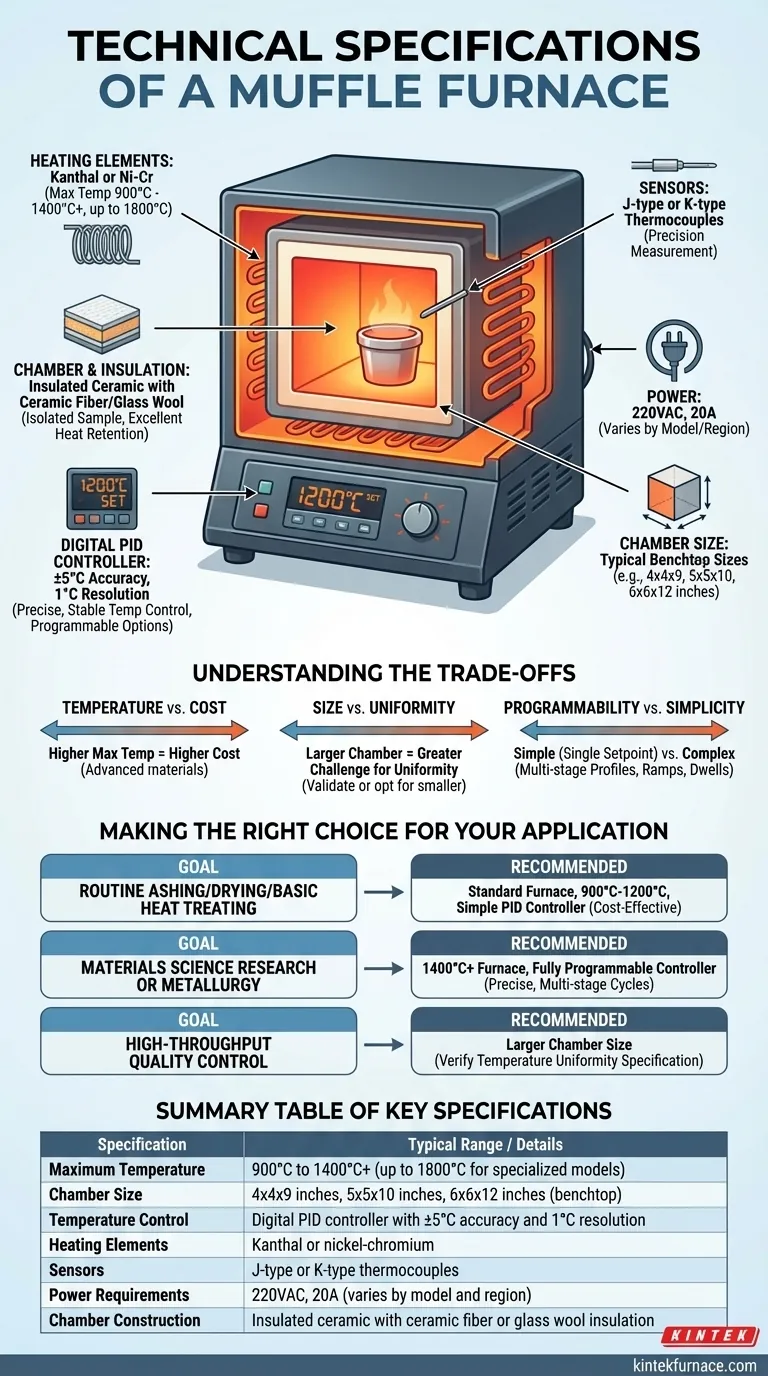

At their core, muffle furnaces are defined by a specific set of technical specifications that determine their performance and application. Typically, this includes a maximum temperature ranging from 900°C to over 1400°C, internal chamber sizes like 4x4x9 inches, and a digital PID controller providing temperature accuracy of around ±5°C. Power requirements are commonly in the range of 220VAC at 20A, with J-type or K-type sensors used for temperature measurement.

Understanding the specifications of a muffle furnace is not about memorizing numbers. It's about translating those numbers into performance capabilities—namely, the ability to achieve a precise, uniform, and contaminant-free heating environment for your specific material or process.

The Anatomy of a Muffle Furnace: Key Specifications Explained

A muffle furnace is a system of interacting components. To choose the right one, you must understand how each specification contributes to the final result.

Maximum Temperature Range

The single most important specification is the maximum achievable temperature. This dictates the applications the furnace is suitable for.

Common temperature tiers are ambient to 900°C, 1200°C, or 1400°C, with specialized models reaching 1700-1800°C. The heating elements, often made of materials like Kanthal or nickel-chromium, determine this upper limit.

Chamber Size and Volume

This specification defines the usable workspace inside the furnace, directly impacting your sample size and throughput.

Typical benchtop sizes include 4 x 4 x 9 inches, 5 x 5 x 10 inches, and 6 x 6 x 12 inches. Larger industrial models are also available for higher-capacity work.

Temperature Control and Accuracy

Precise control is what ensures repeatable and reliable results. Modern furnaces rely on sophisticated digital controllers to manage temperature.

Most quality furnaces use a PID (Proportional-Integral-Derivative) controller. This system intelligently anticipates temperature changes to prevent overshooting the setpoint, ensuring stability.

Look for a stated accuracy of ±5°C or better and a resolution of 1°C. This means the furnace can hold a target temperature with minimal deviation.

The "Muffle": Chamber Construction and Insulation

The defining feature of a muffle furnace is its chamber, which isolates the sample from the heating elements. This prevents contamination from combustion byproducts or direct radiation damage.

The chamber is typically made of insulated ceramic, which provides excellent heat retention. The external body is insulated with high-density ceramic fiber or glass wool to maximize thermal efficiency and keep the exterior safe to touch.

Sensors and Thermocouples

To control the temperature, the furnace must first measure it accurately. This is done with a thermocouple.

The sensor type is matched to the furnace's temperature range. J-type thermocouples are common for lower ranges, while K-type thermocouples are used for higher temperatures (above ~1200°C).

Power and Installation Requirements

This is a practical consideration for facility planning. A common specification is 220VAC, single-phase power, requiring a 20A circuit.

Always verify the specific voltage and amperage required for a model, as this can vary significantly with size and by region (e.g., 110V in North America vs. 220-240V elsewhere).

Understanding the Trade-offs

Selecting a furnace involves balancing competing priorities. Being aware of these trade-offs is crucial for making an informed decision.

Temperature vs. Cost

Higher maximum temperatures are more expensive. Reaching temperatures above 1400°C requires more advanced heating elements, thermocouples, and insulation materials, all of which increase the unit's cost significantly.

Size vs. Uniformity

While a larger chamber allows for processing more samples, it also presents a greater challenge for maintaining perfect temperature uniformity. For applications where every sample must be at the exact same temperature, you may need to validate the uniformity of a larger furnace or opt for a smaller model.

Programmability vs. Simplicity

A simple controller with a single temperature setpoint is easy to operate. However, a programmable PID controller allows for complex heating profiles with multiple steps, ramps (heating rate), and dwells (soak time). This is essential for advanced materials processing but adds complexity.

Making the Right Choice for Your Application

Use your primary goal to guide your selection through the key specifications.

- If your primary focus is routine ashing, drying, or basic heat treating: A standard furnace with a range of 900°C to 1200°C and a simple PID controller is typically sufficient and cost-effective.

- If your primary focus is materials science research or metallurgy: You will likely need a furnace capable of 1400°C or higher with a fully programmable controller to execute precise, multi-stage heat treatment cycles.

- If your primary focus is high-throughput quality control: Prioritize a larger chamber size to meet your capacity needs, but be sure to confirm that its temperature uniformity specification meets the tolerance of your testing protocol.

By understanding how these technical specifications translate into functional performance, you can confidently select the right tool for the job.

Summary Table:

| Specification | Typical Range / Details |

|---|---|

| Maximum Temperature | 900°C to 1400°C+ (up to 1800°C for specialized models) |

| Chamber Size | 4x4x9 inches, 5x5x10 inches, 6x6x12 inches (benchtop) |

| Temperature Control | Digital PID controller with ±5°C accuracy and 1°C resolution |

| Heating Elements | Kanthal or nickel-chromium |

| Sensors | J-type or K-type thermocouples |

| Power Requirements | 220VAC, 20A (varies by model and region) |

| Chamber Construction | Insulated ceramic with ceramic fiber or glass wool insulation |

Ready to enhance your lab's capabilities with a custom muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet precise experimental requirements. Whether you're in materials science, metallurgy, or quality control, we can help you achieve superior, contaminant-free heating. Contact us today to discuss your project and get a personalized solution!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production